Resource utilization method of high-concentration ammonia nitrogen waste liquid

A high-concentration, resource-based technology, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems affecting the quality of etching sub-liquid, avoid ammonia nitrogen re-pollution, and reduce treatment energy consumption , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

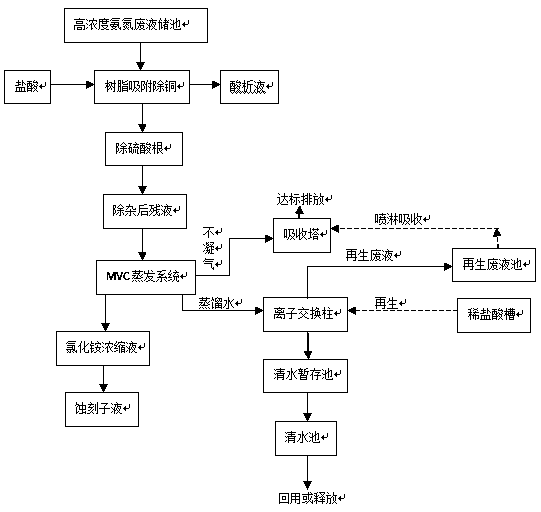

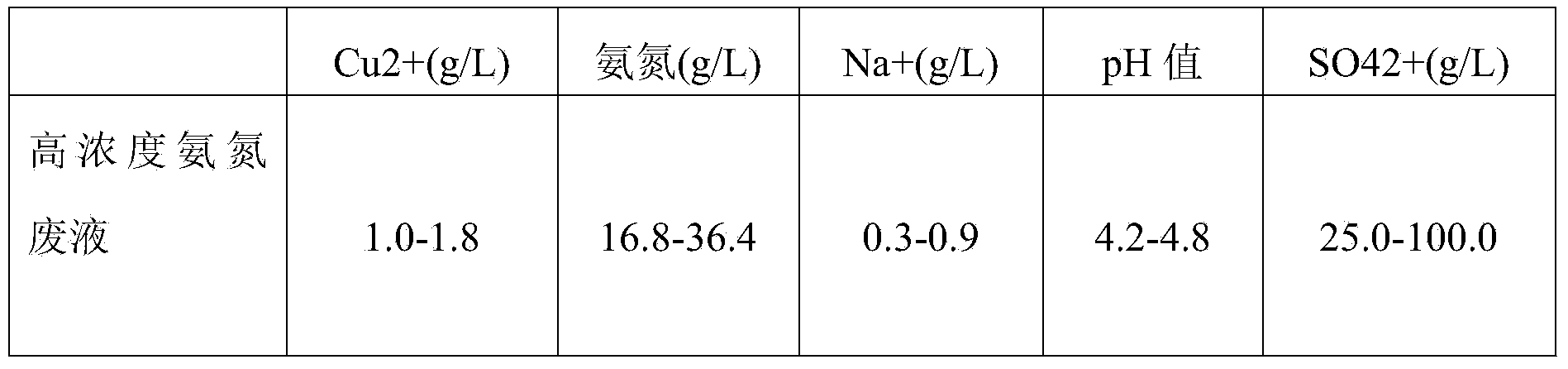

[0022] The following describes the present invention in further detail in combination with specific embodiments, and is not intended to limit the protection scope of the present invention. The composition of the high-concentration ammonia nitrogen waste liquid after copper extraction from the copper-containing etching waste liquid in the circuit board industry is shown in Table 1.

[0023] Table 1 High-concentration ammonia nitrogen waste liquid composition table.

[0024]

[0025] Step 1: Remove impurities.

[0026] (1) 16 cubic meters of copper-containing wastewater collected are slowly added dropwise to a chelating resin column with a height of 1 meter and a volume of 12 cubic meters. The residence time of the waste liquid in the resin column is 1 minute, and it is collected after passing through the ion exchange column. Copper-free ammonia nitrogen wastewater, the copper content in copper-free wastewater is 0.8ppm after testing;

[0027] (2) Use 5% analytically pure hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com