Optical liquid adhesive with high weather resistance and preparation method thereof

A high weather resistance, adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of not meeting product requirements, high refraction and atomization, insufficient flexibility problems, to achieve the effect of small curing shrinkage, low refractive index and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

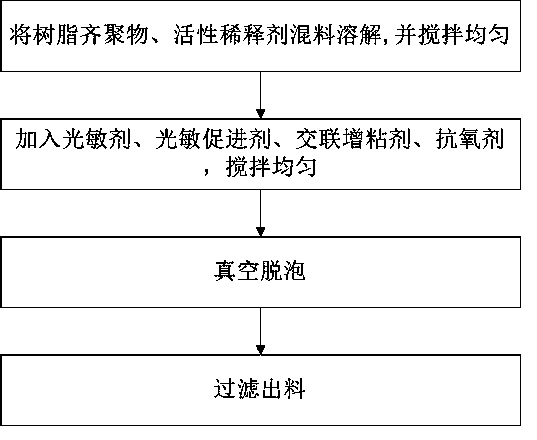

Method used

Image

Examples

Embodiment 1

[0023] The raw materials for making the highly weather-resistant liquid optical adhesive of Example 1 include the following ingredients in proportion by weight:

[0024] Resin Oligomer: Urethane Acrylate 28%

[0026] Reactive Thinner: 6-Hexanediol Diacrylate 23%

[0027] Tripropylene glycol diacrylate 18%

[0028] Photosensitizer: 2-Hydroxy-2-methyl-1-phenyl-1-propanone 1.6%

[0029] Photosensitizer: Ethyl-p-dimethylaminobenzoate 1.2%

[0030] Cross-linking tackifier: Bis-γ-trimethoxysilylpropylamine 1.5%

[0031] Antioxidant: N,N'-bis-[3-(3,5-di-tert-butyl

[0032] yl-4-hydroxyphenyl)propionyl]hydrazine 4.7%

[0033] Add the resin oligomer and reactive diluent weighed according to the above percentage ratio into the reaction kettle, stir at room temperature (25°C) for 1.5 hours, and then add photosensitizer, photosensitization accelerator, crosslinking tackifier, Antioxidant, stirred for 4 hours, until mixed evenly, sampling control technica...

Embodiment 2

[0035] The raw materials for making the highly weather-resistant liquid optical adhesive of embodiment 2 include the following ingredients in proportion by weight:

[0036] Resin Oligomer: Urethane Acrylate 58%

[0037] Reactive diluent: Tripropylene glycol diacrylate 31%

[0038] Photosensitizer: 2-Hydroxy-2-methyl-1-phenyl-1-propanone 3.5%

[0039] Photosensitizer: Ethyl-p-dimethylaminobenzoate 1.4%

[0040] Cross-linking tackifier: γ-Aminopropyltriethoxysilane 1.9 %

[0041] Antioxidant: N,N'-bis-[3-(3,5-di-tert-butyl

[0042] yl-4-hydroxyphenyl)propionyl]hydrazine 4.2%

[0043] Similarly, add the resin oligomer and active diluent weighed according to the above percentage ratio into the reaction kettle, stir at 40°C for 1.5 hours, and then add photosensitizer, photosensitization accelerator, crosslinking tackifier, anti- Oxygen agent, stirred for 4 hours, until mixed evenly, sampling control technical indicators, detection of quality parameters in the usual detection m...

Embodiment 3

[0045] The highly weather-resistant liquid optical adhesive of embodiment 3 comprises the following raw material formula feeding and making by weight ratio:

[0046] Resin Oligomer: Epoxy Acrylate 55%

[0047] Reactive diluent: 6-Hexanediol diacrylate 12%

[0048] Tripropylene glycol diacrylate 23%

[0049] Photosensitizer: 2-Hydroxy-2-methyl-1-phenyl-1-propanone 3.7%

[0050]Photosensitizer: Ethyl-p-dimethylaminobenzoate 0.5%

[0051] Cross-linking tackifier: γ-Aminopropyltriethoxysilane 1.3%

[0052] Antioxidant: Thiodiethylene bis[3-(3,5-ditert-

[0053] Butyl-4-hydroxyphenyl) ester] 4.5%

[0054] The resin oligomer and reactive diluent weighed according to the above weight percentage ratio were added to the reaction kettle, stirred at 30°C for 1.5 hours, and then photosensitizer, photosensitization accelerator, cross-linking tackifier, antioxidant Stir for 4 hours until the mixture is uniform, take samples and check the technical indicators, check the quality paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com