Canned edible fungi production process capable of decomposing imidazole pesticide residues

A technology of pesticide residues and production process, applied in application, food preparation, food science, etc., can solve problems such as processing and production process and process parameters that are not mentioned, and achieve sustainable and healthy development, simple production process and remarkable effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

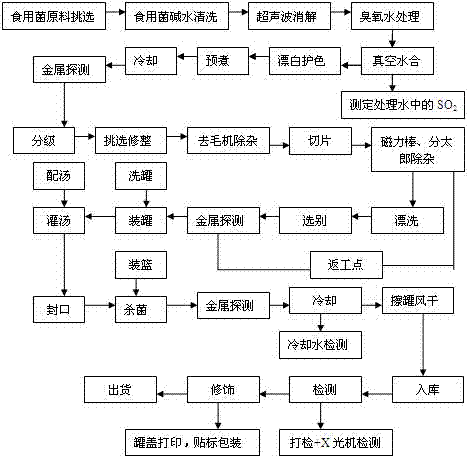

Image

Examples

Embodiment 1

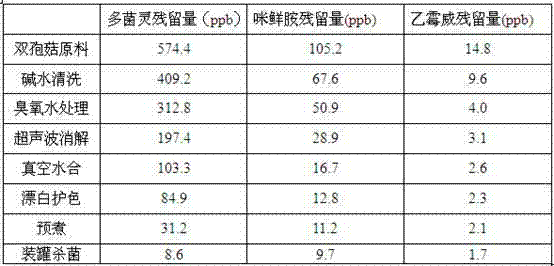

[0031] A method for producing canned Agaricus bisporus for digestion of imidazolic pesticide residues, comprising the following steps:

[0032] (1) Agaricus bisporus acceptance, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0033] (2) To clean Agaricus bisporus, use 5% sodium bicarbonate alkaline water to continuously clean Agaricus bisporus 3 times in a flow cell;

[0034] (3) Ozone water treatment: spread the cleaned Agaricus bisporus into a pile with a thickness of 1-2 cm, and evenly spray the ozone water with a concentration of 5 mg / L on the Agaricus bisporus, and the amount of ozone water used is 0.2% of the weight of the Agaricus bisporus;

[0035] (4) Ultrasonic digestion: the Agaricus bisporus after the ozone water treatment is used at the same time with an ultrasonic frequency of 20kHz and a power of 90w / cm 2 Ultrasound, ultrasonic for 2 hours;

[0036] (5) Vacuum hydration: use sodium bicarbonate alkaline water wi...

Embodiment 2

[0047] A process method for producing canned anchovy mushrooms for digestion of imidazolic pesticide residues, comprising the following steps:

[0048] (1) Acceptance of raw materials of Pteris edodes, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0049] (2) To clean the Pterodactylus, use 3% sodium bicarbonate alkali to clean the Pteris 2 times in the flow cell;

[0050] (3) Ozone water treatment: spread the cleaned Pteris edulis into a pile of 1~2cm thick, and spray evenly on Pteris edulis with a concentration of 10 mg / L. 0.6%;

[0051] (4) Ultrasonic digestion: the Pteris cerevisiae after treatment with ozone water, using an ultrasonic frequency of 35kHz and a power of 60w / cm 2 Ultrasound, ultrasonic 3h;

[0052] (5) Vacuum hydration: use sodium bicarbonate alkaline water with a concentration of 5wt%, hydrate under vacuum conditions twice, each time for 10 minutes, and the vacuum degree is 0.08 Mpa;

[0053] (6) Bleach...

Embodiment 3

[0059] A method for producing canned Coprinus comatus that digests imidazolic pesticide residues, comprising the following steps:

[0060] (1) Coprinus comatus acceptance, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0061] (2) Coprinus comatus is cleaned by using 1% sodium bicarbonate alkaline water to continuously clean Coprinus comatus twice in a flow cell;

[0062] (3) Ozone water treatment: spread the cleaned Coprinus comatus to a thickness of 1-2 cm, and evenly spray the ozone water with a concentration of 15 mg / L on the raw material of Coprinus comatus edible fungus. 1%;

[0063] (4) Ultrasonic digestion: Coprinus comatus treated with ozone water, using an ultrasonic frequency of 25kHz and a power of 75w / cm 2 Ultrasound, ultrasonic 3h;

[0064] (5) Vacuum hydration: use sodium bicarbonate alkaline water with a concentration of 5wt%, hydrate under vacuum conditions twice, each time for 10 minutes, and the vacuum deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com