Method for preparing ceramic tile from high-aluminum fly ash

A high-aluminum fly ash and ceramic technology, which is applied in the field of waste utilization of coal combustion residues, can solve the problems of not having ceramic bricks, and achieve the effects of environmental protection, huge economic benefits, social value, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

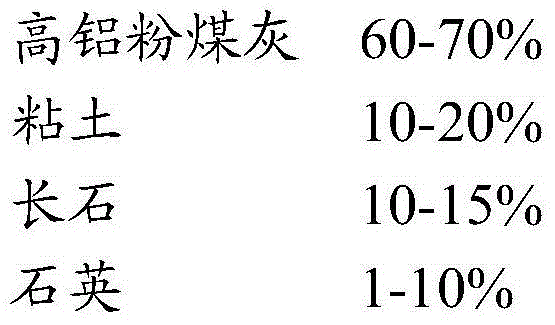

Method used

Image

Examples

Embodiment 1

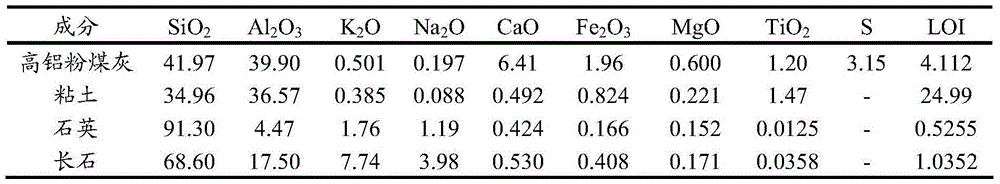

[0082] A, batching: take the raw material in the above table 1 of following mass percentage: 70% high alumina fly ash, 14% clay, 12% feldspar, 4% quartz, then mix uniformly, obtain batching;

[0083] B, ball milling: the batching is packed in the ball mill, and add water and anhydrous sodium carbonate and carry out ball milling, wherein the mass ratio of batching, ball mill grinding ball and water is 1:1:1.5, the quality of added anhydrous sodium carbonate is batching 0.1% of the mass; the ball milling time is 10 hours, and the sieve with ten thousand holes is 0.5%;

[0084] C. Slurry and drying: Slurry after ball milling is carried out, and the slurry is removed by an electromagnetic powder iron remover with a magnetic field strength of 10,000 gauss, and then dried at 80°C until the moisture content in it is 4 %;

[0085] D, granulation: grind the dried material in step C, mix and granulate, and pass through a 100-mesh sieve twice;

[0086] E. Stale: Encapsulate and stale f...

Embodiment 2

[0091] A. Ingredients: Weigh the raw materials in the above table 1 in the following mass percentages: 64% high-alumina fly ash, 15% clay, 12% feldspar, 9% quartz, and then mix them evenly to obtain the ingredients:

[0092] B, ball mill: batching is packed in ball mill, and add water and anhydrous sodium carbonate and carry out ball milling, wherein the mass ratio of batching, ball mill grinding ball and water is 1:1.5:2.5, the quality of added anhydrous sodium carbonate is batching 0.2% of the mass; the ball milling time is 15 hours, and the sieve with ten thousand holes is 0.7%;

[0093] C. Slurry and drying: Slurry after ball milling is carried out, and the slurry is removed by an electromagnetic powder iron remover with a magnetic field strength of 20,000 gauss, and then dried at 100°C until the moisture content in it is 5 %;

[0094] D, granulation: Grind, mix and granulate the dried material in step C, and pass through a 100-mesh sieve for 3 times;

[0095] E. Stale: ...

Embodiment 3

[0100] A. Ingredients: Weigh the raw materials in the above table 1 in the following mass percentages: 66% high alumina fly ash, 13% clay, 15% feldspar, 6% quartz, and then mix evenly to obtain the ingredients:

[0101] B, ball mill: batching is packed in the ball mill, and add water and anhydrous sodium carbonate and carry out ball milling, wherein the mass ratio of batching, ball mill grinding ball and water is 1:2:3, the quality of added anhydrous sodium carbonate is batching 0.3% of the mass; the ball milling time is 20 hours, and the remainder of the 10,000-hole sieve is 0.8%;

[0102] C. Slurry and drying: Slurry after ball milling is carried out, and the slurry is removed by an electromagnetic powder iron remover with a magnetic field strength of 30,000 gauss, and then dried at 110°C until the moisture content in it is 6 %;

[0103] D, granulation: Grind the dried material in step C, and pass through a 100-mesh sieve twice;

[0104] E. Stale: Encapsulate and stale for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com