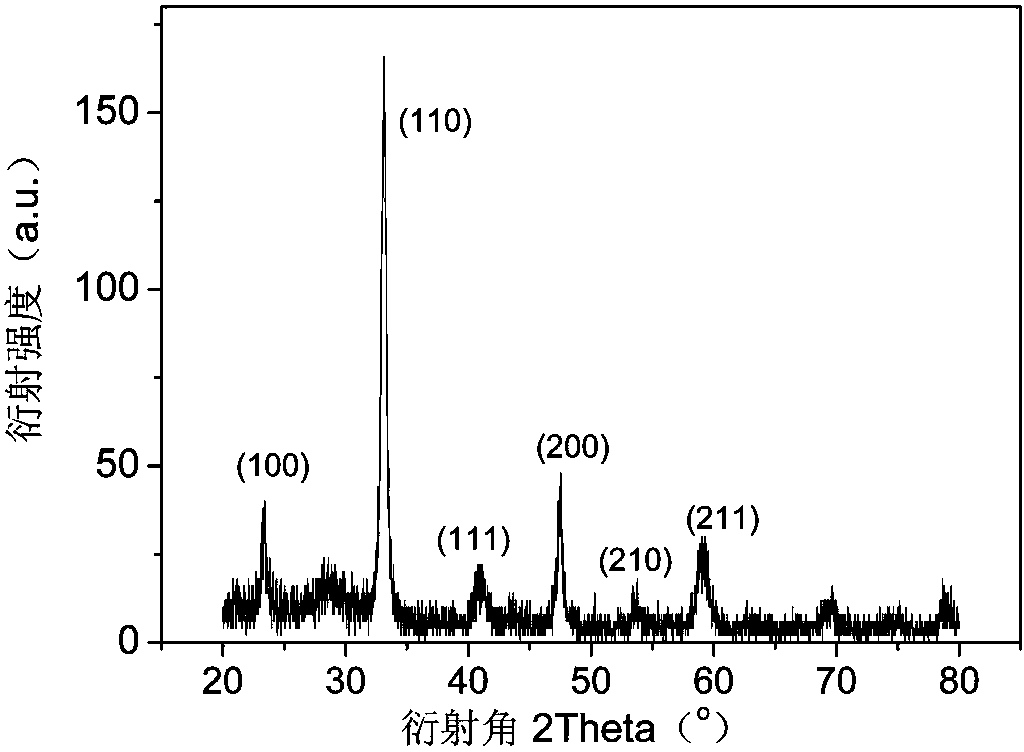

Preparation method of lanthanum nickelate conductive film by chemical solution deposition

A technology of chemical solution deposition and conductive thin film, which is applied to the direction of conductive layer on the insulating carrier, which can solve the problem of the gap in the conductivity of the thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of chemical solution deposition preparation method of lanthanum nickelate conductive thin film, its steps are as follows:

[0023] 1) Using nickel acetate as raw material, nickel acetate was dissolved in ethylene glycol methyl ether, and acrylic acid was added as complexing agent to prepare Ni solution. After stirring the Ni solution for 1.5 hours to obtain a clear solution, add lanthanum nitrate powder and continue stirring until it becomes clear to obtain LaNiO 3 sol, the LaNiO 3 The molar ratio of nickel acetate, lanthanum nitrate, acrylic acid and ethylene glycol methyl ether in the sol is 1: 1.3: 2:30.

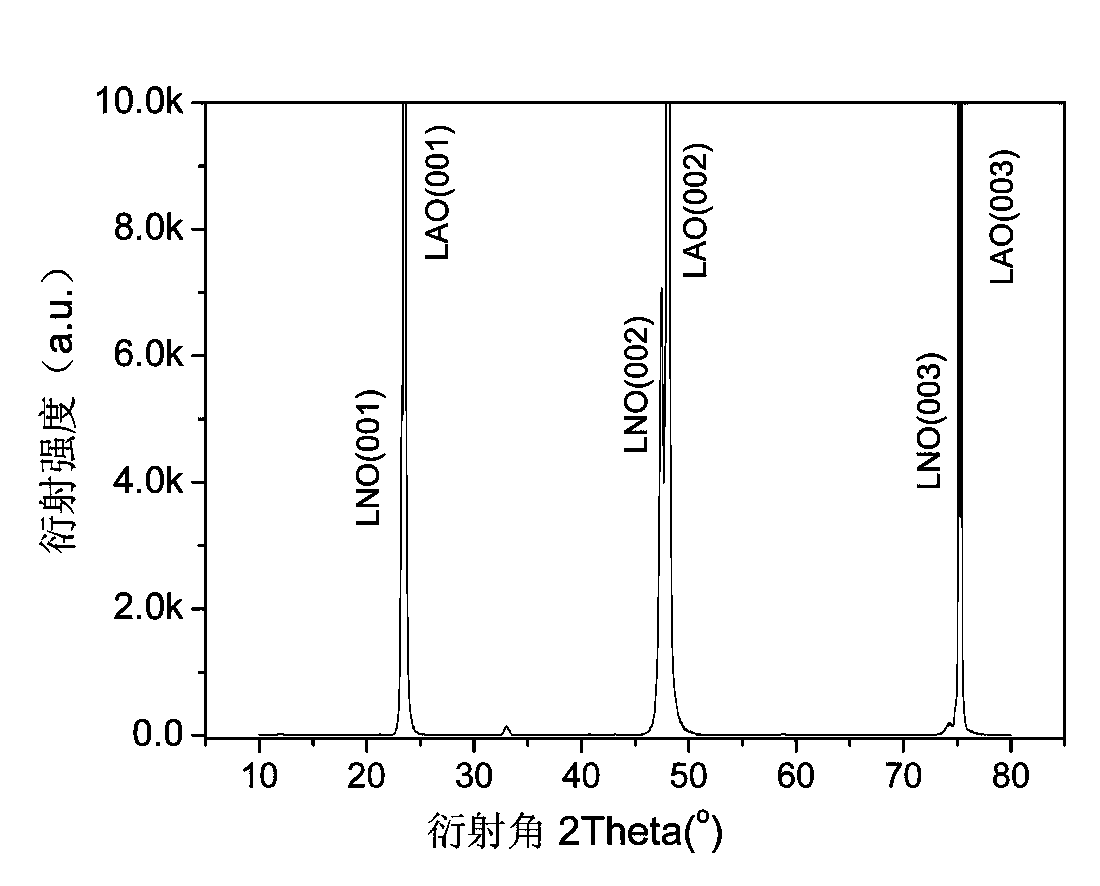

[0024] 2) LaNiO prepared in step 1) 3 Sol, prepared LaNiO on LAO single crystal substrate by dip-pulling method 3 gel film, which will subsequently be covered with LaNiO 3 The substrate of the gel film was dried at 150 °C for 10 min to make the LaNiO 3 The gel film dries to form LaNiO 3 Gel dry film.

[0025] 3) The obtained step 2) with LaNiO 3 The ...

Embodiment 2

[0032] A kind of chemical solution deposition preparation method of lanthanum nickelate conductive thin film, its steps are as follows:

[0033] 1) Using nickel acetate as raw material, dissolve nickel acetate in ethylene glycol methyl ether, add acrylic acid as a complexing agent to prepare Ni solution, stir Ni solution for 3 hours to obtain a clear solution, add lanthanum nitrate powder, and continue stirring clarification, LaNiO can be obtained 3 Sol, the molar ratio of nickel acetate, lanthanum nitrate, acrylic acid, and ethylene glycol methyl ether in the sol is 1:1.3:2:40.

[0034] 2) LaNiO prepared in step 1) 3 Sol, LaNiO prepared on Si single crystal substrates by spin-coating 3 gel film, which will subsequently be covered with LaNiO 3 The substrate of the gel film was dried at 100 °C for 10 min to make the LaNiO 3 The gel film dries to form LaNiO 3 Gel dry film.

[0035] 3) The obtained step 2) with LaNiO 3 The Si substrate of the gel dry film is tra...

Embodiment 3

[0042] A kind of chemical solution deposition preparation method of lanthanum nickelate conductive thin film, its steps are as follows:

[0043] 1) Using nickel acetate as raw material, nickel acetate was dissolved in ethanol, and propionic acid was added as complexing agent to prepare Ni solution. After stirring the Ni solution for 1 hour to obtain a clear solution, add lanthanum nitrate powder and continue stirring to clarify, and then LaNiO can be obtained. 3 Sol, the molar ratio of nickel acetate, lanthanum nitrate, propionic acid, and ethanol in the sol is 1:1.2:2:40.

[0044] 2) LaNiO prepared in step 1) 3 Sol, LaNiO prepared on LAO single crystal substrates by spin-coating 3 gel film, which will subsequently be covered with LaNiO 3 The substrate of the gel film was dried at 120 °C for 10 min to make LaNiO 3 The gel film dries to form LaNiO 3 Gel dry film.

[0045] 3) The obtained step 2) with LaNiO 3 The LAO single crystal substrate of the gel dry film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com