Silver/silver bromide/silver metavanadate plasma compound photocatalyst and preparation method thereof

A silver metavanadate and plasma technology is applied in the field of photocatalysis, which can solve the problem of low utilization rate of catalysts, and achieve the effects of superior photodegradation performance, convenient industrial production and short production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

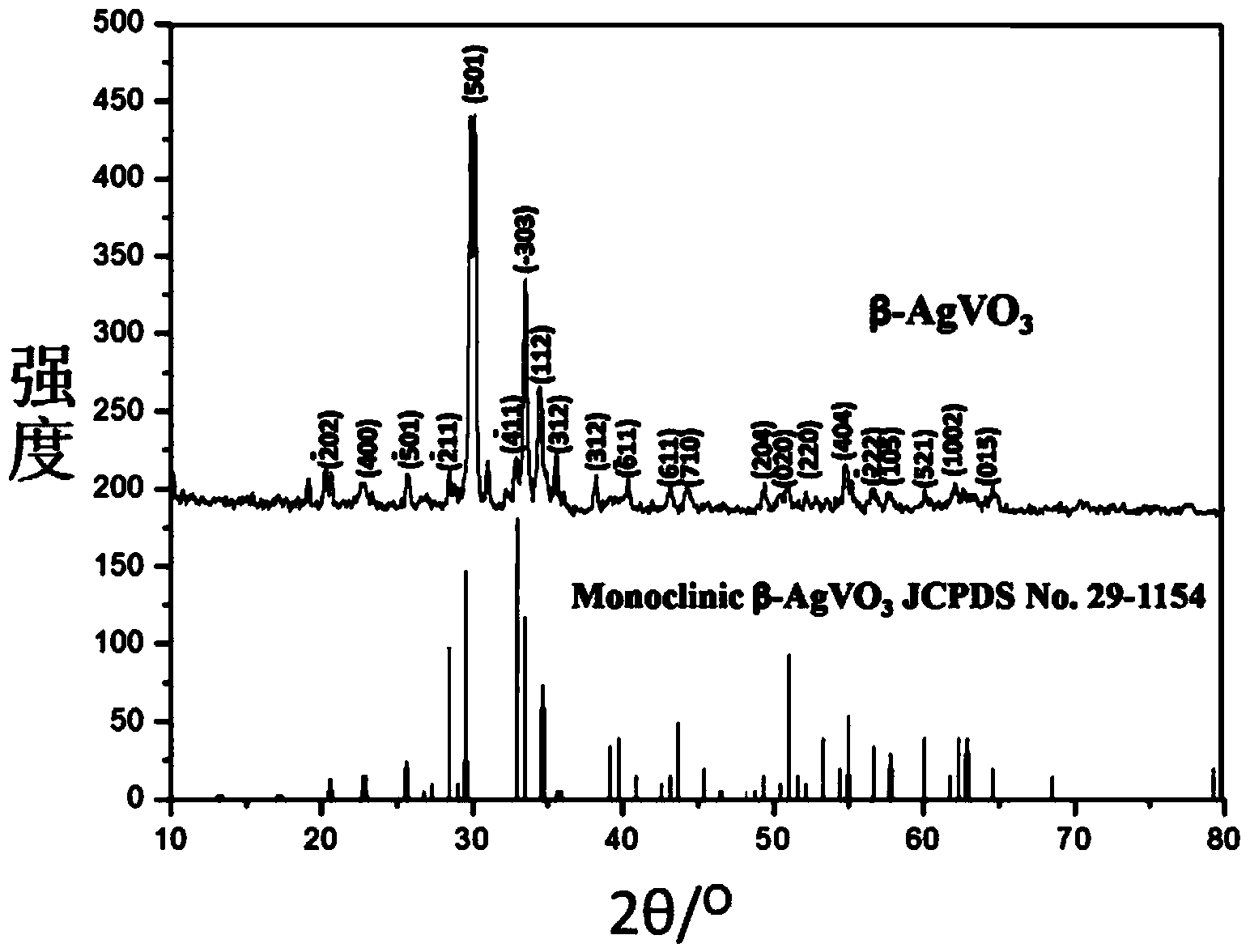

[0035] A kind of preparation method of silver / silver bromide / silver metavanadate plasma composite photocatalyst

[0036] (1) Weigh 1 mmol of ammonium metavanadate into a clean beaker, add 20 mL of distilled water, and stir on a magnetic stirrer to dissolve it completely. After it dissolves, add 1 mmol of silver nitrate while stirring, and continue stirring for 10 minutes; after stirring, transfer the obtained solution into a stainless steel autoclave with a capacity of 20mL polytetrafluoroethylene liner and react at 140°C for 12h . After the reaction time is up, take out the reaction kettle, cool it down to room temperature naturally, take out the precipitated product in the kettle, centrifuge, wash the precipitated product with ethanol and distilled water respectively, and finally place it in a vacuum drying oven at 60°C for 6 hours to obtain the product Silver Metavanadate.

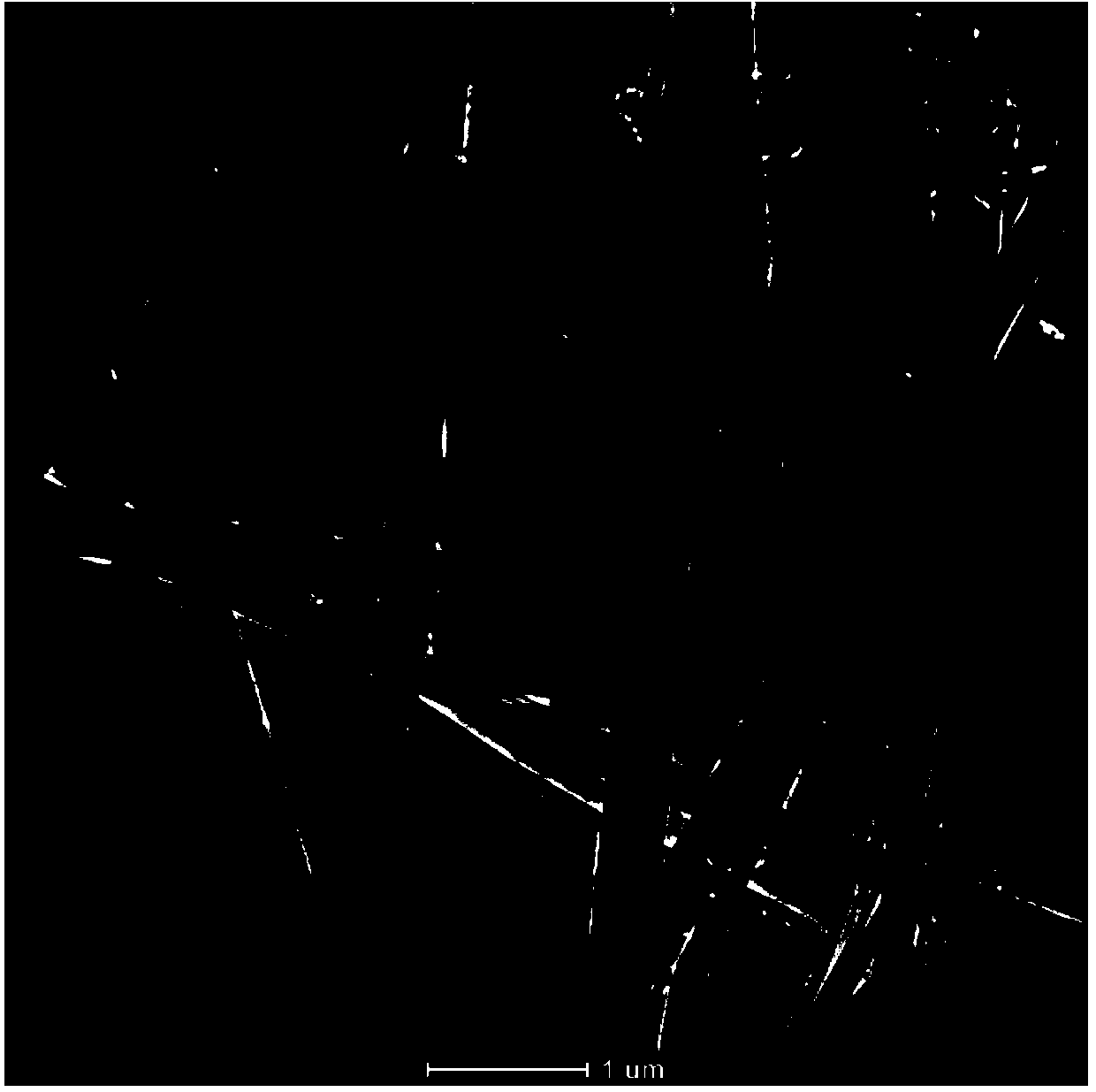

[0037] (2) Disperse the silver metavanadate nanobelts in distilled water at 25°C to a concentratio...

Embodiment 2

[0040] (1) Weigh 1 mmol of ammonium metavanadate into a clean beaker, add 20 mL of distilled water, and stir on a magnetic stirrer to dissolve it completely. After it dissolves, add 1 mmol of silver nitrate while stirring, and continue stirring for 10 minutes; after stirring, transfer the obtained solution into a stainless steel autoclave with a capacity of 20mL polytetrafluoroethylene liner and react at 160°C for 12h . After the reaction time is up, take out the reaction kettle, cool it down to room temperature naturally, take out the precipitated product in the kettle, centrifuge, wash the precipitated product with ethanol and distilled water respectively, and finally place it in a vacuum drying oven at 60°C for 6 hours to obtain the product Silver Metavanadate.

[0041] (2) Disperse the silver metavanadate nanobelts in distilled water at 20°C to a concentration of 0.1mol / dm 3 The surfactant dodecyltrimethylammonium bromide was slowly added dropwise to the silver metavanad...

Embodiment 3

[0044] (1) Weigh 1 mmol of ammonium metavanadate into a clean beaker, add 20 mL of distilled water, and stir on a magnetic stirrer to dissolve it completely. After it dissolves, add 1 mmol of silver nitrate while stirring, and continue stirring for 10 minutes; after stirring, transfer the obtained solution into a stainless steel autoclave with a capacity of 20mL polytetrafluoroethylene liner and react at 160°C for 24h . After the reaction time is up, take out the reaction kettle, cool it down to room temperature naturally, take out the precipitated product in the kettle, centrifuge, wash the precipitated product with ethanol and distilled water respectively, and finally place it in a vacuum drying oven at 60°C for 8 hours to obtain the product Silver Metavanadate.

[0045] (2) Disperse the silver metavanadate nanobelts in distilled water at 0°C, and the concentration is 0.1mol / dm 3 The surfactant dodecyltrimethylammonium bromide was slowly added dropwise to AgVO 3 solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com