Catalyst for preparing propylene by directly converting ethylene, and application method thereof

A catalyst and ethylene technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low propylene yield and achieve high propylene yield, strong acidity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the catalyst for the direct conversion of ethylene to propylene provided by the invention comprises the following steps:

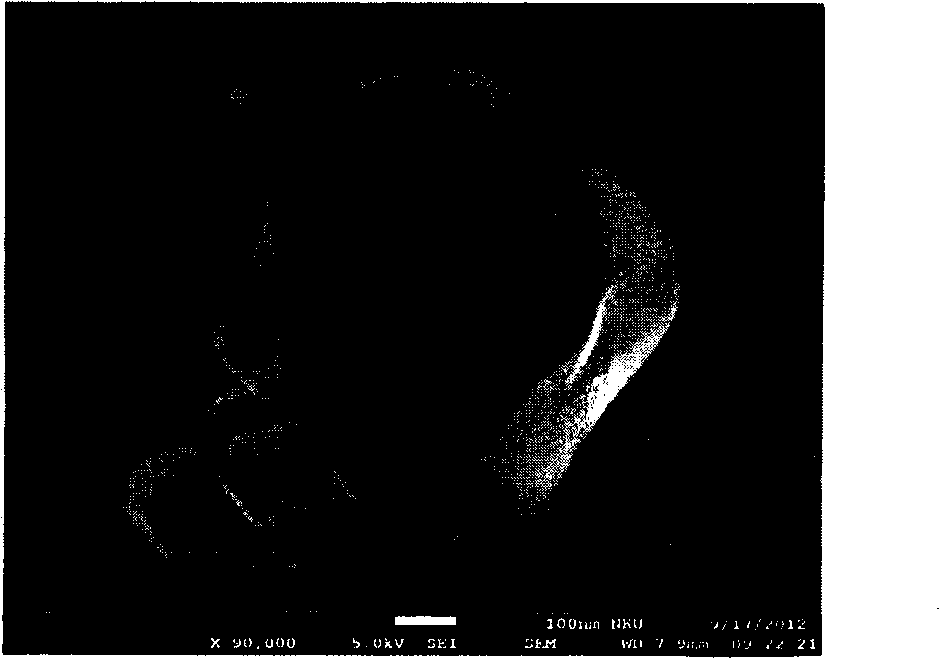

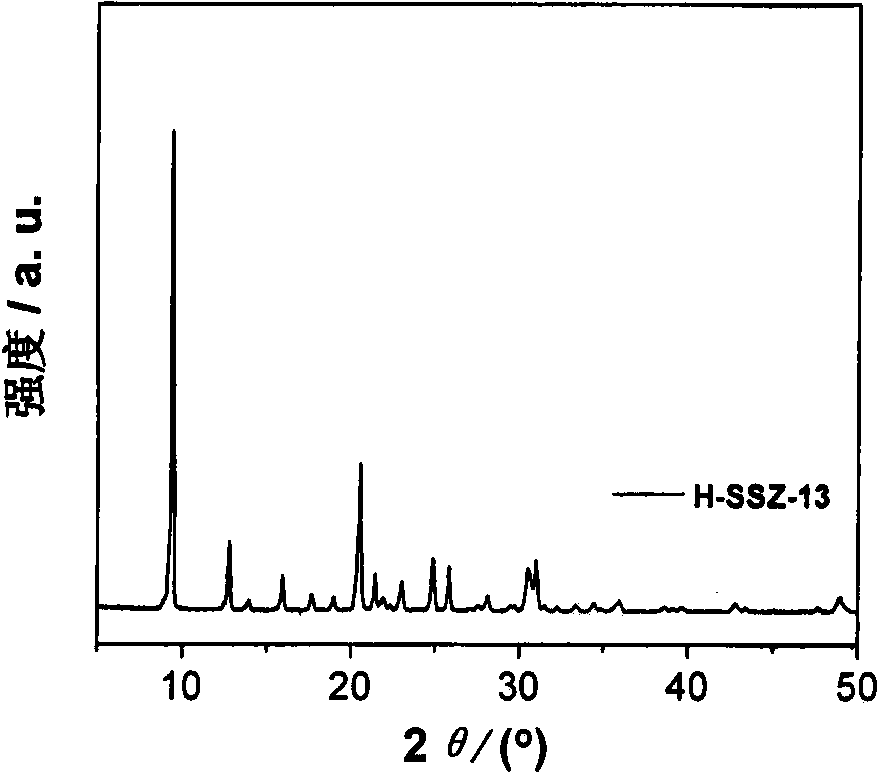

[0023] 1) Treat the original powder of H-SSZ-13 catalyst (the main components are Si, O and Al, where SiO2 / Al2O3=27) under the condition of concentrated acid (concentrated nitric acid, concentrated hydrochloric acid or acetic acid), and the treatment temperature is 25 -150℃, the treatment time is 5-60h;

[0024] 2) The acid-treated catalyst is calcined in an air atmosphere in a muffle furnace for 4-6 hours, and the calcining temperature is 500-600°C.

[0025] The former powder of H-SSZ-13 catalyst described in the present invention is purchased from Tianjin Shenneng Technology Co., Ltd., silicon-aluminum ratio (SiO 2 / Al 2 o 3 ) is 27; the obtained H-SSZ-13 is then treated with concentrated acid (that is, the catalyst is placed in a concentrated acid solution and stirred at different temperatures) to obtain a catalyst f...

Embodiment 2

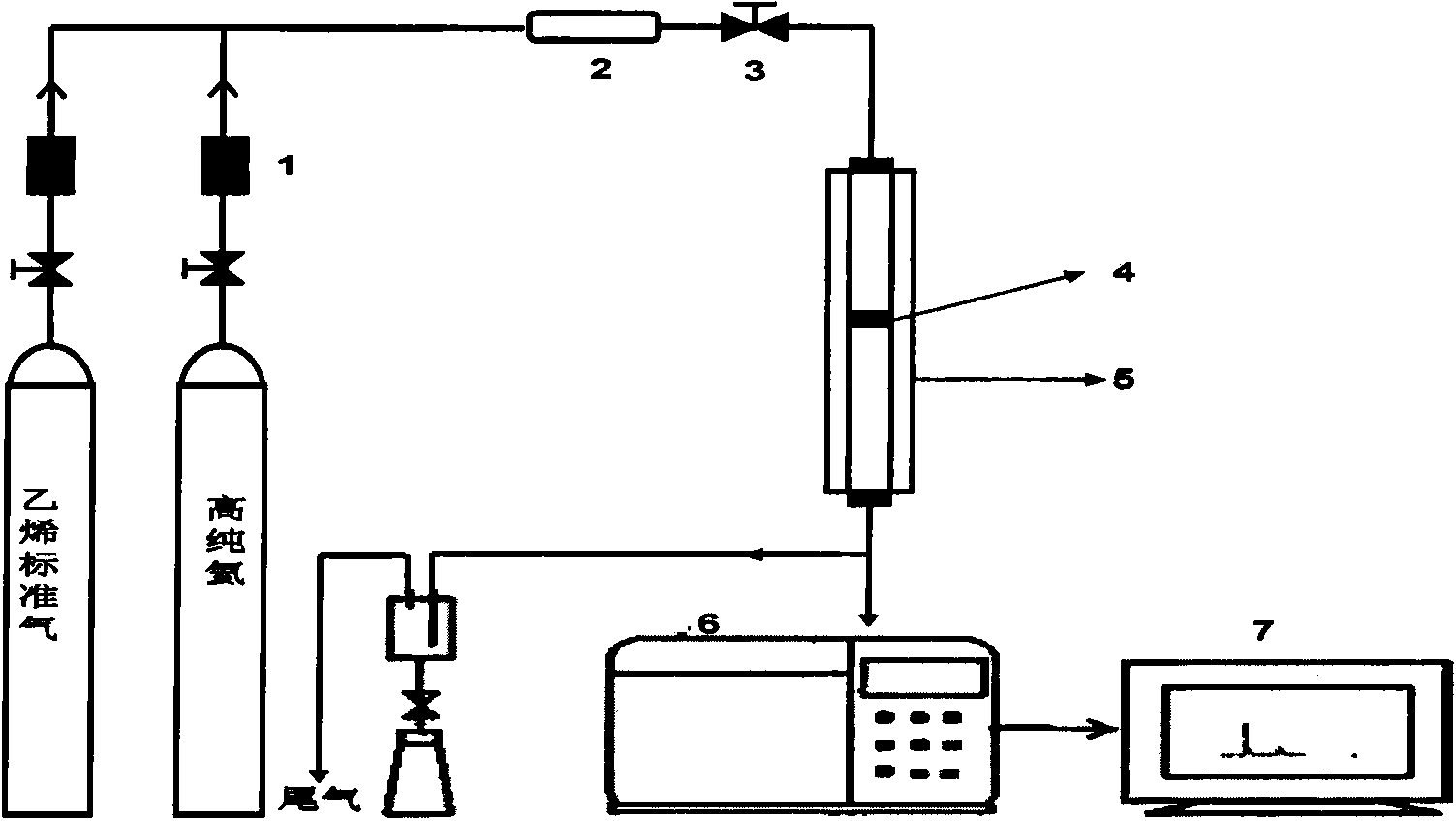

[0039] Weigh 1.0g each of catalyst samples X-5, Y-5 and C-5 after being treated with nitric acid, hydrochloric acid and acetic acid for 5 hours respectively, press into tablets and sieve, weigh 0.1g of 20-40 mesh samples and put them into the reaction device , the carrier gas flow rate is 20ml min -1 , the reaction pressure is normal pressure, and the space velocity of ethylene is 1.0h -1 , the reaction temperature is 400°C. The sampling time was 15 minutes, and the test results of the catalytic reaction are shown in Table 2.

[0040] The test results show that the conversion rate of ethylene and the selectivity of propylene are also different under the same reaction conditions for samples treated with different types of acids. Among them, the samples treated with nitric acid and acetic acid had better activity in ethylene conversion reaction. The conversion rate of ethylene reaches above 80%, and the selectivity of propylene also reaches above 55%.

[0041] Table 2 Test r...

Embodiment 3

[0044]Weigh samples X-5, X-10, X-20, X-40, X-60 and C-5, C-10, C-20, C-40, C-60 each 1.0g, after tableting and sieving, weigh 0.1g and put them into the reaction device, the carrier gas flow rate is 20ml min -1 , the reaction pressure is normal pressure, and the space velocity of ethylene is 1.0h -1 , the reaction temperature is 400°C. The sampling time was 15 minutes, and the test results of the catalytic reaction are shown in Table 3.

[0045] Table 3 Test results of ethylene to propylene

[0046]

[0047]

[0048] The test results showed that with the increase of acid treatment time, the conversion rate of ethylene and the selectivity of propylene increased first and then decreased, among which the acid treatment time of 40 h was the most suitable. The ethylene conversion rate on X-40 is 84.7%, and the propylene selectivity is 62.2%; the ethylene conversion rate on C-40 is 82.6%, and the propylene selectivity is 60.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com