Silica gel loaded type catalyst and application of catalyst in Baeyer-Villiger reaction

A supported catalyst and catalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve poor solubility, difficult catalyst recovery and reuse, loss of enzyme activity, etc. problems, to achieve the effect of simple recycling, improved cleaning and safety, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Step 1, preparation of silica gel supported catalyst:

[0019] 1. Add 1g of silica gel to a three-necked flask, pour 10ml of concentrated nitric acid to submerge the silica gel, and react at 80°C for 8 hours. After the reaction, filter and dry to obtain the product. This step is to remove impurities in the silica gel by acid treatment.

[0020] 2. Add the silica gel from the previous step into the three-necked flask, use ethanol as the solvent, add 1ml of phenyltrimethoxysilane coupling agent, add acetic acid to adjust the pH to about 4, and react at 70°C for 15h. After the reaction, pour the mixture into distilled water, filter while hot, and dry the product.

[0021] 3. Add the product from the previous step into a three-necked flask, add 5mL of 98wt% sulfuric acid for sulfonation, the reaction time is 20h, and the temperature is 30°C. After the reaction, pour into water to fully precipitate, filter, and dry to obtain a silica gel-loaded catalyst.

[0022] 4. A...

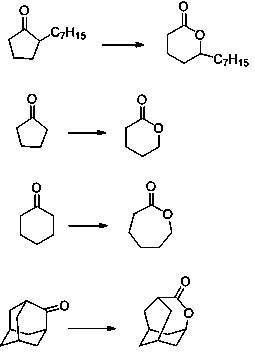

Embodiment 1

[0028] In a 50 mL three-neck flask, add 0.45 g of 2-heptylcyclopentanone, dropwise add hydrogen peroxide with a mass fraction of 30%, the molar ratio of hydrogen peroxide to 2-heptylcyclopentanone is 2.5 / 1, and then Add a silica gel-supported catalyst whose mass is 20% of the mass of 2-heptylcyclopentanone, stir with a magnetic force, and react at 40° C. for 24 hours. The mixture was filtered through a glass funnel to remove the catalyst. The filtrate was left standing to separate the organic phase. Take 2 mL of 5% sodium bicarbonate aqueous solution to wash the organic phase three times, then wash with distilled water until the organic phase is neutral, adjust the aqueous phase to weak alkalinity with 5% sodium bicarbonate aqueous solution and extract with ethyl acetate, The ethyl acetate extract was combined with the organic phase, vacuum rotary evaporated, vacuum rotary evaporated solvent, weighed and analyzed by gas chromatography. The conversion of 2-heptylcyclopent...

Embodiment 2

[0032] In a 50 mL three-necked flask, add 0.21 g of cyclopentanone, dropwise add hydrogen peroxide with a mass fraction of 30%, the molar ratio of hydrogen peroxide to cyclopentanone is 2.5 / 1, and then add a silica gel-supported catalyst, the mass fraction of which is 20% of the mass of cyclopentanone, stirred by magnetic force, and reacted at 10°C for 24 hours. The mixture was filtered through a glass funnel to remove the catalyst. The filtrate was left standing to separate the organic phase. Take 2 mL of 5% sodium bicarbonate aqueous solution to wash the organic phase three times, then wash with distilled water until the organic phase is neutral, adjust the aqueous phase to weak alkalinity with 5% sodium bicarbonate aqueous solution and extract with ethyl acetate, The ethyl acetate extract was combined with the organic phase, the solvent was evaporated in vacuo, weighed and analyzed by gas chromatography. The conversion of cyclopentanone was 70%. The yield of delta-va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com