Elastic epoxy resin waterproof coating and preparation method thereof

A technology of epoxy resin and waterproof coating, which is applied in the direction of epoxy resin coating, coating, etc., to achieve the effect of low application cost, simple preparation method, and improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

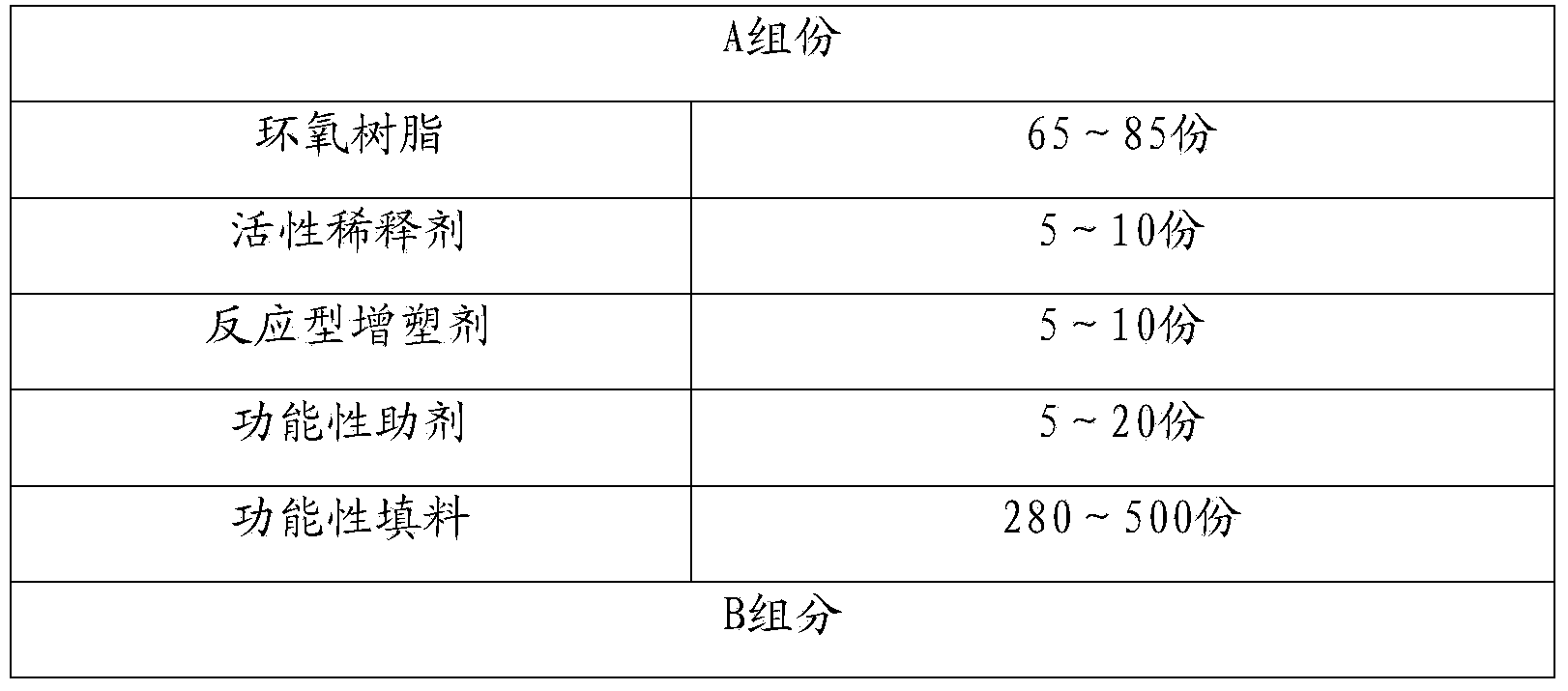

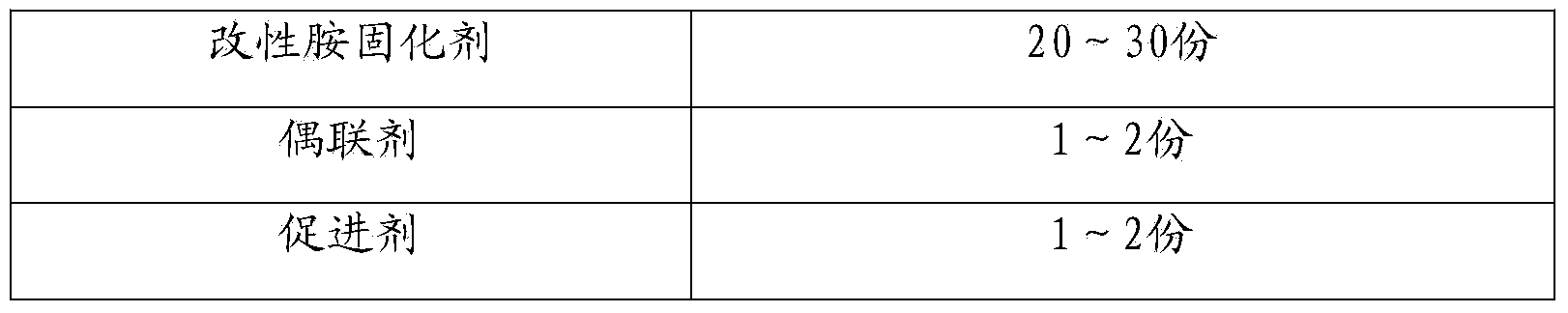

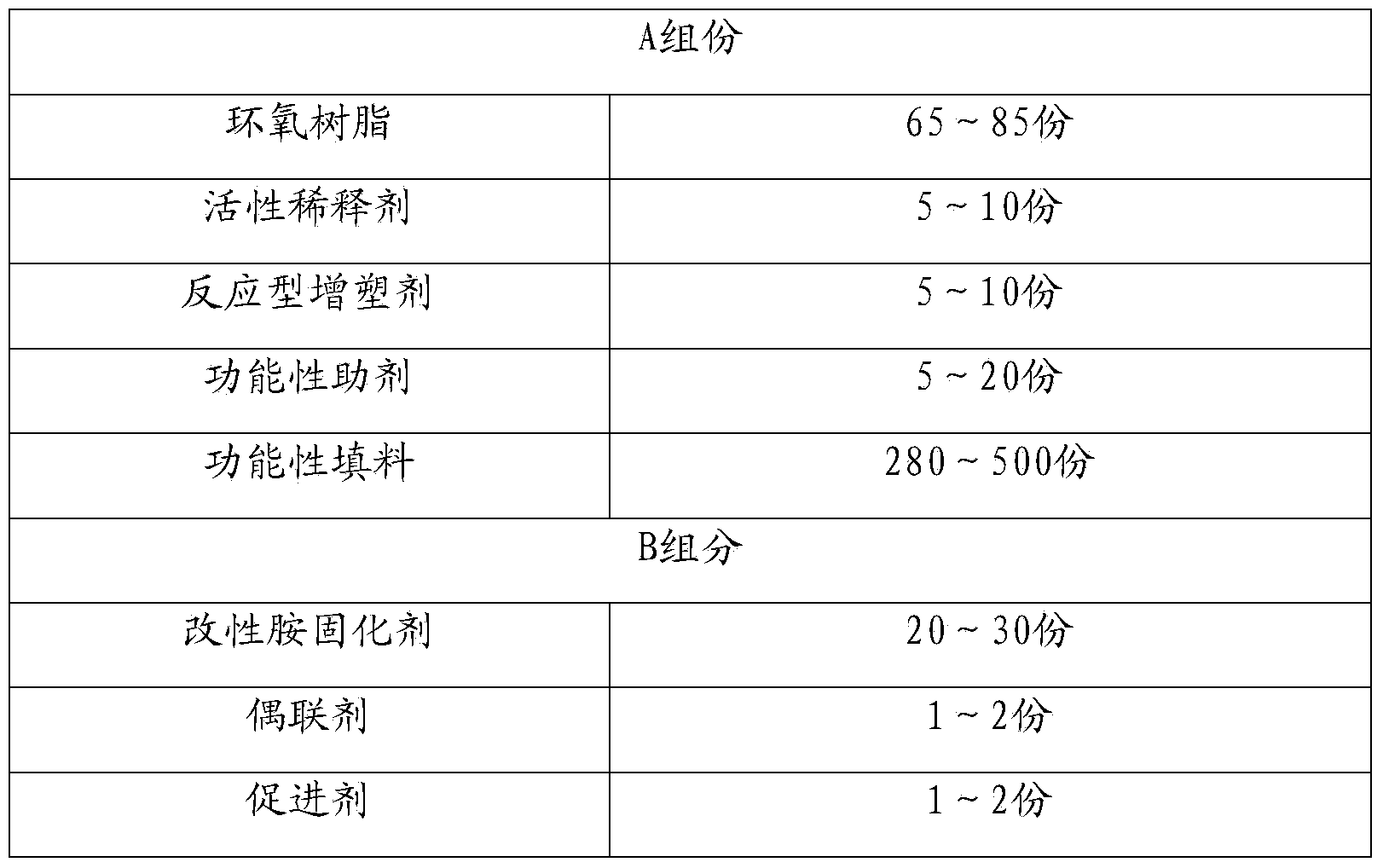

Method used

Image

Examples

Embodiment 1

[0027] 65 parts by weight of bisphenol A liquid epoxy resin E51, 8 parts by weight of butyl glycidyl ether, 1 part by weight of wetting agent (HX-4020), 1 part by weight of defoamer (BYK-A500 foam breaking polymer solution), 1 part by weight of leveling agent (polyester-modified polydimethylsiloxane solution), 2 parts by weight of plasticizer (methacrylate), 280 parts of functional filler (quartz powder 40, barium sulfate 40 , wollastonite 40, mica powder 40, talc powder 40, white cement 40, gray cement 40) mixed evenly to obtain component A;

[0028] Mix 20 parts by weight of butyl glycidyl ether modified amine curing agent, 2 parts by weight of anilinomethyltriethoxysilane, and 2 parts by weight of triethanolamine to obtain component B;

[0029] Mix components A and B evenly to obtain an elastic epoxy resin waterproof coating;

Embodiment 2

[0031] 65 parts by weight of bisphenol A liquid epoxy resin E51, 8 parts by weight of butyl glycidyl ether, 1 part by weight of wetting agent (HX-4040), 1 part by weight of defoamer (BYK-052 without silicone break Foam polymer solution), 1 weight part of leveling agent (acrylate leveling agent SKR-1153), 2 weight parts of plasticizer (fumarate), 200 mesh sieve of white cement to get 30 weight parts, 15 weight parts Barium sulfate, 15 parts by weight of 325 mesh quartz powder, 15 parts by weight of 600 mesh heavy calcium, and 300 parts by weight of 80-120 mesh quartz sand are mixed uniformly to obtain the A component mixture described in claim 1;

[0032] Mix 20 parts by weight of butyl glycidyl ether modified amine curing agent, 2 parts by weight of anilinomethyltriethoxysilane, and 2 parts by weight of triethanolamine to obtain component B;

[0033] Mix component A and component B uniformly in proportion to obtain elastic epoxy resin waterproof coating;

Embodiment 3

[0035] 65 parts by weight of bisphenol F epoxy resin, 8 parts by weight of butyl glycidyl ether, 1 part by weight of wetting agent (HX-4020), 1 part by weight of defoamer (BYK-052 without silicone foam breaking polymerization solution), 1 part by weight of leveling agent (polyester modified polydimethylsiloxane solution), 2 parts by weight of plasticizer (acrylic acid ester), 30 parts by weight and 15 parts by weight of white cement through a 200 mesh sieve Barium sulfate, 15 parts by weight of 325 mesh quartz powder, 15 parts by weight of 600 mesh heavy calcium, and 300 parts by weight of 80-120 mesh quartz sand are uniformly mixed to obtain the A component described in claim 1;

[0036] Mix 20 parts by weight of butyl glycidyl ether modified amine curing agent, 2 parts by weight of anilinomethyltriethoxysilane, and 2 parts by weight of triethanolamine to obtain component B;

[0037] Mix component A and component B uniformly in proportion to obtain elastic epoxy resin waterpr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com