Manganese zinc aluminate luminescent material and preparation method thereof

A luminescent material, zinc aluminate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems affecting device performance, weaken electron emission, etc., and achieve enhanced luminous intensity, stable chemical properties and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

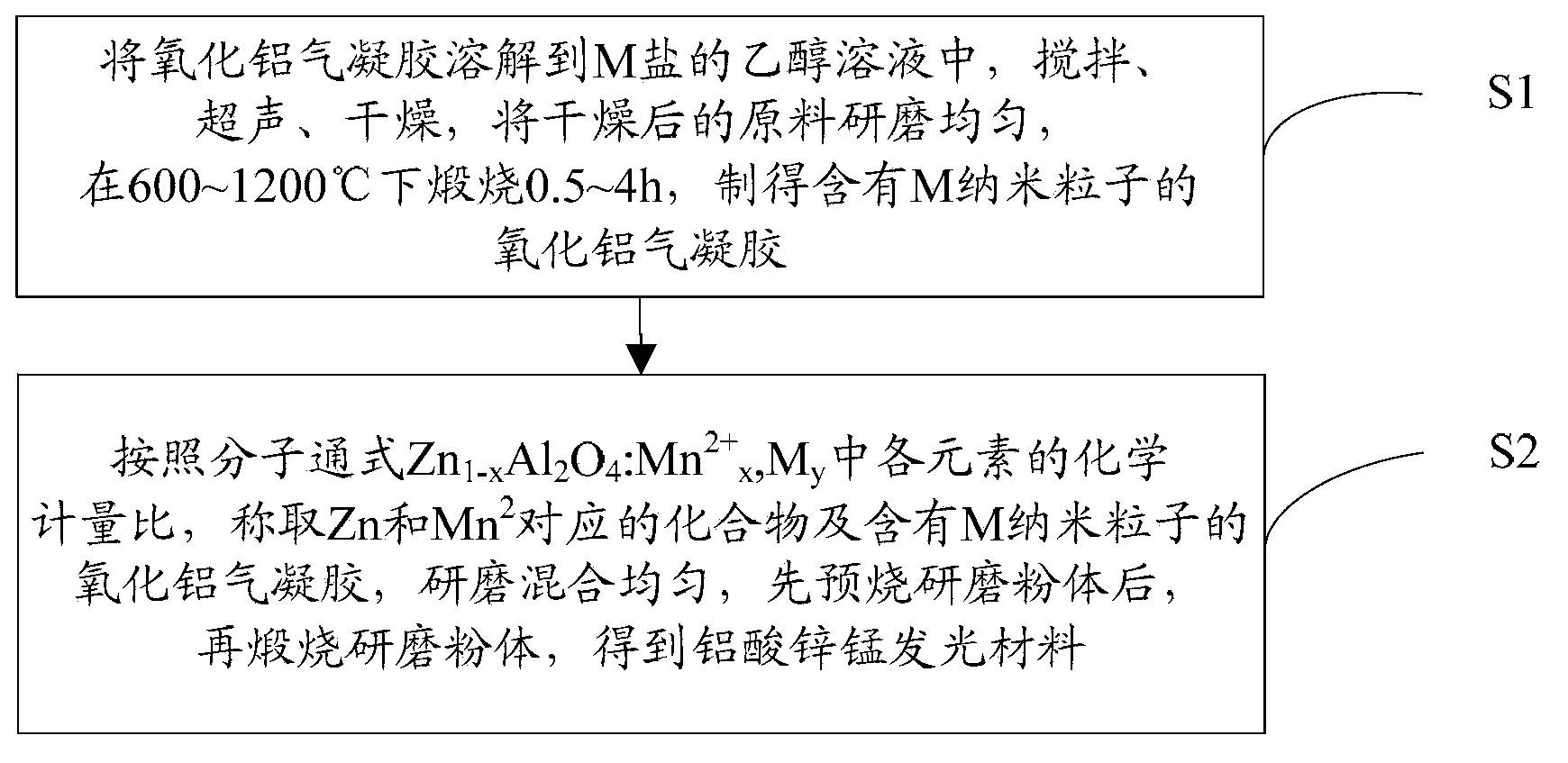

[0022] The preparation method of the above-mentioned zinc-manganese aluminate luminescent material comprises the following steps:

[0023] S1: Dissolve the alumina airgel in the ethanol solution of M salt, stir at 50-75°C for 0.5-3h, then sonicate for 10min, then dry at 60-150°C, grind the dried raw materials evenly, Calcining at 600-1200°C for 0.5-4 hours to prepare alumina airgel containing M nanoparticles; wherein, the molar ratio of alumina to M is greater than 0 and less than or equal to 5×10 -3 , preferably, the molar ratio of alumina to M is 5×10 -6 ~2.5×10 -3

[0024] S2, according to the general molecular formula Zn 1-x al 2 o 4 :Mn 2+ x ,M y For the stoichiometric ratio of each element in the formula, weigh the compounds corresponding to Zn and Mn and the alumina airgel containing M nanoparticles prepared in step S1, grind and mix evenly, heat up to 800 ° C ~ 1400 ° C for pre-calcination for 2 ~ 15 hours, then calcined at 1000°C-1400°C for 0.5-6 hours in air...

Embodiment 1

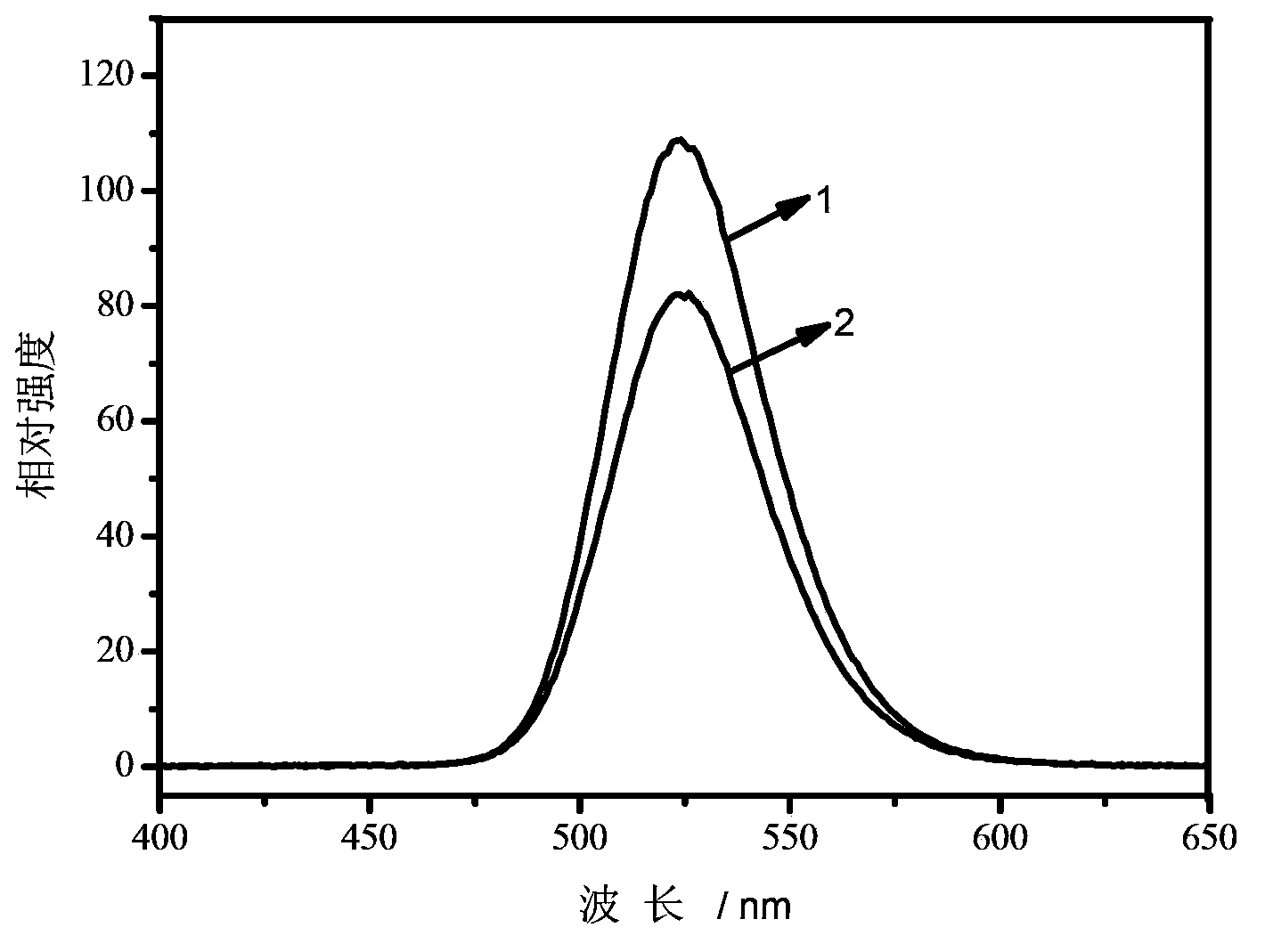

[0031] Example 1: Zn 0.999 Al 2 o 4 :Mn 2+ 0.001 ,

[0032] First weigh 0.6116g of alumina airgel, dissolve it to 24ml containing palladium chloride (PdCl 2 2H 2 O) 5×10 -6 mol / L ethanol solution, stirred at 65°C for 1.5h, then ultrasonicated for 10min, then dried at 120°C, ground the dried sample evenly, and pre-calcined at 1100°C for 2h to obtain aluminum oxide gas containing metal ions gel.

[0033] Then weigh the ZnC 2 o 4 2H 2 O 0.7569g, 0.4078g of Al containing metal ions 2 o 3 Aerogel, MnC 2 o 4 2H 2 O 0.0006g, put it in an agate mortar and grind until it is evenly mixed, then transfer the powder to a corundum crucible, heat-treat in a muffle furnace at 1400°C for 2h, and then sinter at 1400°C for 0.5h in a weak reducing atmosphere of CO , cooled to room temperature, you can get Pd-doped Zn 0.999 Al 2 o 4 :Mn 2+ 0.001 , Luminescent material.

Embodiment 2

[0034] Example 2: Zn 0.98 Al 2 o 4 :Mn 0.01 ,

[0035] First weigh 0.6117g of alumina airgel, dissolve it to 12ml containing auric acid chloride (HAuCl 4 )1×10 -2 mol / L ethanol solution, stirred at 75°C for 0.5h, then ultrasonicated for 10min, then dried at 150°C, ground the dried sample evenly, and pre-calcined at 1200°C for 0.5h to obtain aluminum oxide containing metal ions airgel.

[0036] Then weigh ZnCO 3 0.3073g, Al containing metal ions 2 o 3 Airgel 0.2549g, MnCO 3 0.0028g, put it in an agate mortar and grind it until it is evenly mixed, then transfer the powder to a corundum crucible, heat treat in a muffle furnace at 800°C for 15h, then sinter at 1000°C in an air atmosphere for 4h, and cool to room temperature. Get metal-doped Zn 0.98 Al 2 o 4 :Mn 0.01 , Luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com