Method for preparing biodiesel through trichosporon cutaneum

A technology of Trichosporium dermatosa and biodiesel, which is applied in the fields of bioenergy and biocatalysis, can solve the problems of increased production costs and the probability of infection with miscellaneous bacteria, and achieve the effects of easy control, high yield, and slow heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

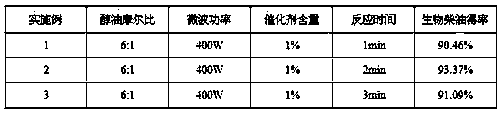

Embodiment 1

[0026] A kind of method utilizing Trichosporium dermatosa yeast to prepare biodiesel, comprises the following steps:

[0027] 1) Preparation of inulin extract: Weigh 5kg of fresh Jerusalem artichoke, wash it with water, slice it with a slicer, spread it outdoors to dry, then put it in an oven, and dry it at 65°C until the water content is below 5%. After pulverizer pulverizes, cross 100 mesh sieves and make about 1.3kg Jerusalem artichoke powder. Weigh 100g of Jerusalem artichoke powder and dissolve it in 900mL of distilled water, place it in a constant temperature water bath, heat it in a water bath at 85°C for 80 minutes, centrifuge at 4000r / min for 10 minutes, remove the precipitate, and take the supernatant as the inulin extract;

[0028] 2) Preparation of lipid-producing medium: Enzymolyze the inulin extract prepared in step 1). Enzymolysis conditions: adjust the pH value of the inulin extract to 4.6 with 1 mmol / L HCl, add 3 mL of exo-inulinase enzyme solution with an en...

Embodiment 2

[0034] A kind of method utilizing Trichosporium dermatosa yeast to prepare biodiesel, comprises the following steps:

[0035] 1) The preparation of the inulin extract is the same as in Example 1;

[0036] 2) The preparation of lipid-producing medium is the same as that in Example 1;

[0037] 3) Trichospora dermatosus oil preparation, the same as in Example 1;

[0038] 4) Biodiesel preparation

[0039] Take 5g of the Trichospora dermatosus oil prepared in step 3) and place it in a one-necked flask, and irradiate it in a microwave oven for a certain period of time to remove moisture. Weigh 0.05g of NaOH required for the reaction and dissolve it in 30g of anhydrous methanol to prepare a catalyst methanol solution. The prepared catalyst methanol solution was poured into the flask, and then the flask was put into a microwave oven for heating. The microwave power was 400W, the heating time was 2.0min, and the reaction was carried out with stirring. After the reaction is finished...

Embodiment 3

[0042] A kind of method utilizing Trichosporium dermatosa yeast to prepare biodiesel, comprises the following steps:

[0043] 1) The preparation of the inulin extract is the same as in Example 1;

[0044] 2) The preparation of lipid-producing medium is the same as that in Example 1;

[0045] 3) Trichospora dermatosus oil preparation, the same as in Example 1;

[0046] 4) Biodiesel preparation

[0047] Take 5g of the Trichospora dermatosus oil prepared in step 3) and place it in a one-necked flask, and irradiate it in a microwave oven for a certain period of time to remove moisture. Weigh 0.05g of NaOH required for the reaction and dissolve it in 30g of anhydrous methanol to prepare a catalyst methanol solution. The prepared catalyst methanol solution was poured into the flask, and then the flask was put into a microwave oven for heating. The microwave power was 400W, the heating time was 3.0min, and the reaction was carried out with stirring. After the reaction was finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com