A method for preparing high f-value collagen peptides by hydrolyzing anglerfish skin

A collagen peptide and collagen protein technology, which is applied in the field of hydrolyzing anglerfish skin to prepare high F-value collagen peptides, can solve the problems of ineffective use of anglerfish skin waste, lack of preparation of high-F value fish collagen peptides, etc., and achieve effective Good for human body absorption, relatively small molecule, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

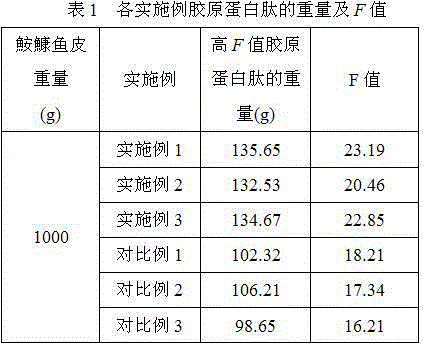

Embodiment 1

[0030] Take 1000 g of washed anglerfish skin, and cut it into fragments with a length and width of about 2 cm × 2 cm with scissors. Add 25L of 4.5% NaOH solution to the anglerfish skin fragments, soak for 24 hours, take it out, and then wash with water until the pH is neutral. Add 35L of 9% n-butanol solution to the fish skin, stir for 28 hours, take it out, wash with water and drain. Crush the drained anglerfish skin fragments, add citric acid solution with a mass fraction of 4%, heat to 55°C, and continuously stir and extract After 6 hours, the crude collagen extract was obtained after filtration. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 0.5h. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 30Hz, and the electric field intensity as 25kV / cm. After taking it out, add 1% pepsin to the crude collagen extract based on the mass of the crud...

Embodiment 2

[0032]Take 1000 g of washed anglerfish skin, and cut it into fragments with a length and width of about 2 cm × 2 cm with scissors. Add 25L of 2.5% NaOH solution to the anglerfish skin fragments, soak for 30 hours, take it out, and then wash with water until the pH is neutral. Then add 35L 9% n-butanol solution to the fish skin, take it out after stirring for 20 hours, wash with water and drain. Crush the drained anglerfish skin fragments, add 1% acetic acid solution with a mass fraction of 1% acetic acid solution according to the solid-liquid ratio of fish skin and acetic acid solution, heat to 65°C, and continuously stir and extract for 7 hours. After filtering, the crude collagen extract was obtained. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 1 h. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 40Hz, and the electric field intensity as...

Embodiment 3

[0034] Take 1000 g of washed anglerfish skin, and cut it into fragments with a length and width of about 2 cm × 2 cm with scissors. Add 25L of 5.5% NaOH solution to the anglerfish skin fragments, soak for 28 hours, take out, and then wash with water until the pH is neutral. Add 35L of 9% n-butanol solution to the fish skin, stir for 25 hours, take it out, wash with water and drain. Crush the drained anglerfish skin fragments, add citric acid solution with a mass fraction of 2% according to the ratio of fish skin and citric acid solution to 1:5, heat to 90°C, and continuously stir to extract After 5 hours, the crude collagen extract was obtained after filtration. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 0.8h. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 35Hz, and the electric field intensity as 20kV / cm. After taking it out, add 1.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com