Compound cutting tool coating based on titanium diboride and preparation method thereof

A composite tool, titanium diboride technology, applied in the direction of tool, coating, metal material coating process for lathes, etc., to achieve the effects of good toughness, high electrical conductivity, thermal conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

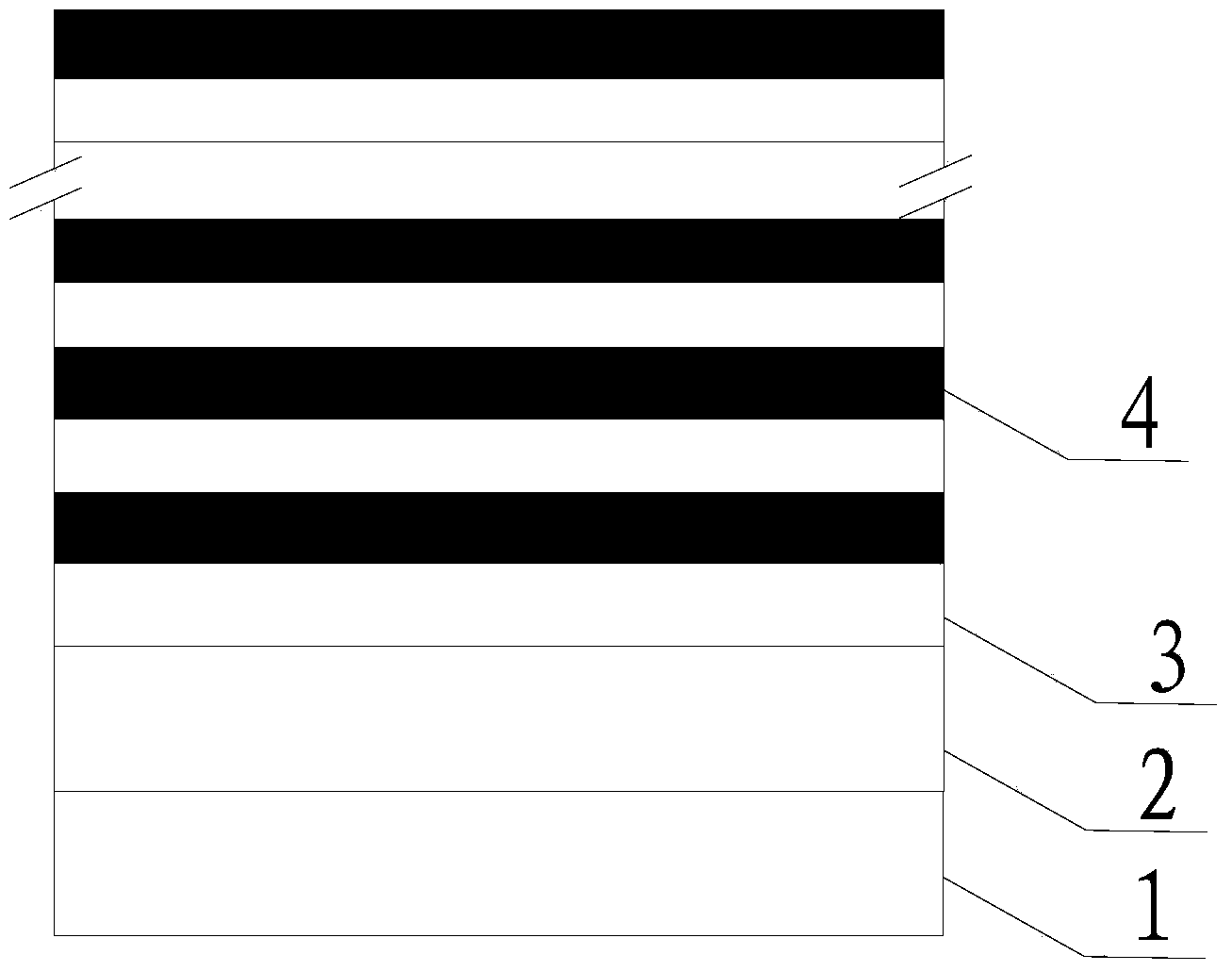

[0024] This example provides a composite tool coating based on titanium diboride for attachment to a substrate 1, mainly consisting of TiB 2 - Ni layer 3 and DLC-Ni layer 4, also transition layer 2 between substrate 1 and composite tool coating. Among them, TiB 2 -Ni layer 3 refers to TiB 2 and Ni composite layer, the DLC-Ni layer 4 is a diamond-like carbon and Ni composite layer, which are alternately laminated and have a thickness of nanometer size. Thanks to TiB 2 -Ni layer and DLC-Ni layer are alternately stacked, and the high hardness and high electrical conductivity of DLC are used to make the composite tool coating have the advantages of good toughness, good thermal conductivity and electrical conductivity, and its hardness can reach 20GPa.

[0025] In this example, TiB 2 -Ni layer 3 is first attached to transition layer 2 (metallic Ni layer), followed by DLC-Ni layer 4 with TiB 2 -Ni layers 3 are alternately stacked. TiB 2 The thickness of -Ni layer 3 and DLC-Ni...

Embodiment 2

[0027] This example provides a method for preparing a titanium diboride-based composite tool coating, which specifically includes the following steps:

[0028] (a) Choose commercially available TiB with a purity of 99.9% 2 Ceramic targets, commercially available metal Ni targets with a purity of 99.99% and carbon targets were installed on a multi-target magnetron sputtering apparatus; Ultrasonic cleaning of the substrate with ethanol for 10-20 minutes, then air-dried at 80°C for 1-2 hours, and then installed on a multi-target magnetron sputtering apparatus;

[0029] (b) Check that the gas, electricity, and water circuits of the multi-target magnetron sputtering instrument are normal, then turn on the main power supply and start the mechanical pump. When the pressure in the deposition chamber and the sample chamber is below 10Pa, close the gap between the mechanical pump and the chamber. valve, open the flapper valve, start the molecular pump, unscrew the gate valve, when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com