Flexible bonded magnet and preparation method thereof

A bonded magnet and flexible technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, adhesives, etc., can solve the problems of low production efficiency, large line deformation rate, and not too high operating temperature, so as to improve production efficiency and high Effects of mechanical properties and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a high-temperature-resistant flexible bonded magnet and its preparation method, which is similar to the general flexible magnet processing method. Firstly, various raw materials are proportioned according to the formula requirements, and they are fully mixed, and then mixed in an open mill or The kneading is uniform in a belt-press kneader, and the obtained kneaded product is rolled into a predetermined thickness in a calender to obtain a single-layer thin magnetic sheet. Then put 2-5 sheets of the thin magnetic sheets into a mold, heat and hold pressure for 10-30 minutes to obtain a composite magnetic sheet, the holding temperature is 150-170° C., and the holding pressure is 5-20 MPa. This heat preservation and pressure holding process is the process of eliminating magnet strain and internal stress added in the preparation method of the present invention. This process is actually compressing the magnetic sheet, which helps to eliminate the strain ...

Embodiment 1

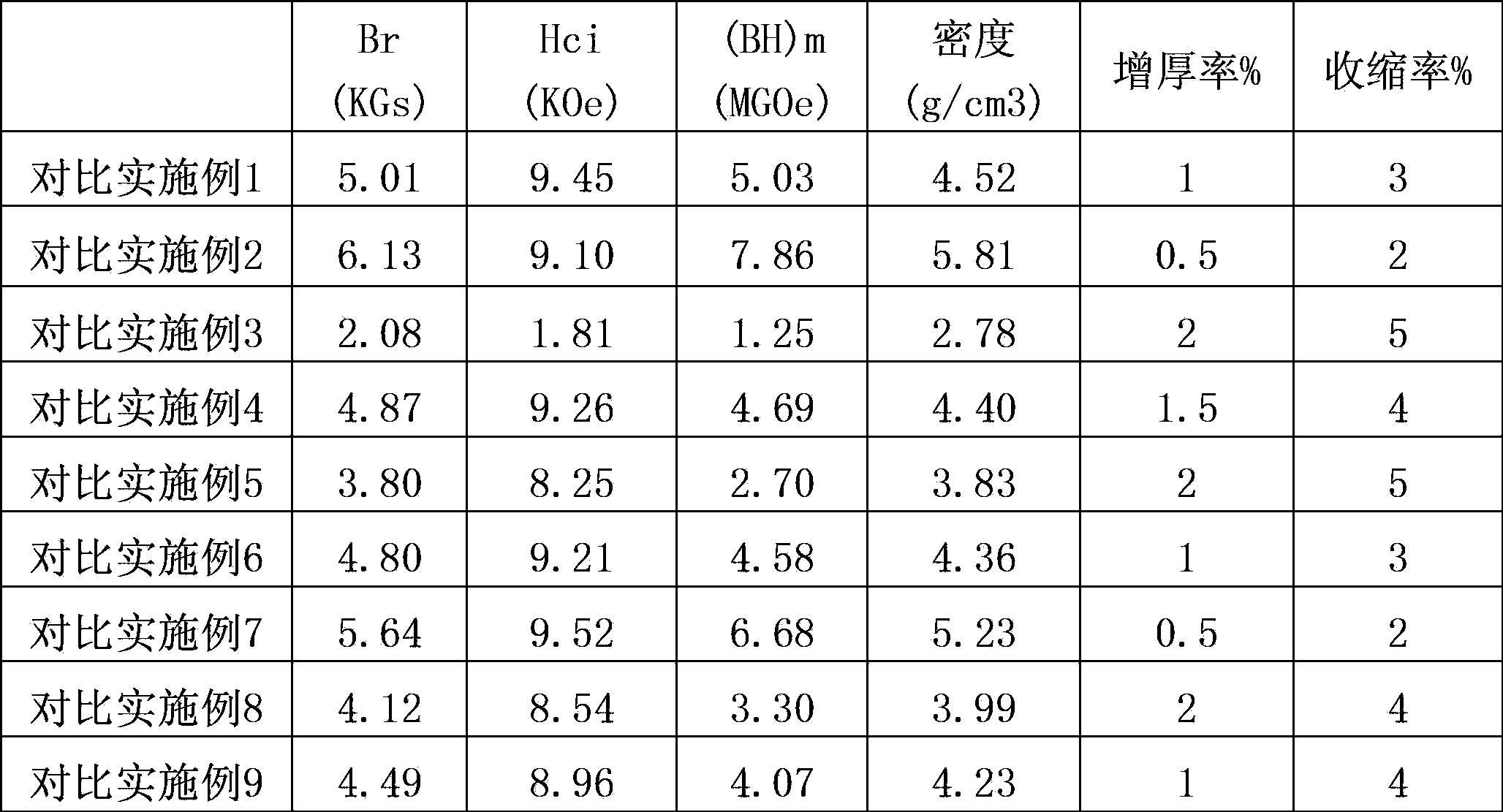

[0028] Bonded NdFeB magnetic powder (particle size 60μm, coupled with 0.1wt% surfactant vinyltriethoxysilane) 92wt%, polyurethane 5.0wt%, zinc stearate 0.8wt%, phthalate Dioctyl ester 1.0wt%, epoxidized soybean oil 1.0wt%, antioxidant triethylene glycol bis[3-(3-tert-butyl-5-methyl-4-hydroxyphenyl)propionate] 0.2wt%. First put the above components and magnetic powder into a high-speed mixer and mix them evenly, then knead the resulting mixture fully with an open mill, then put the resulting mixture on a calender to obtain a thin magnetic sheet with a thickness of 0.6mm, and finally put the 2-layer The thin magnetic sheets are laminated, compressed and maintained at 150° C. under a pressure of 5 MPa for 10 minutes, and finally a magnetic sheet with a thickness of 1.0 mm is obtained. The specific parameters are shown in Table 1 below.

Embodiment 2

[0030]Bonded NdFeN magnetic powder (particle size 40μm, coupled with 3wt% surfactant γ-aminopropyltriethoxysilane) 97wt%, polyethylene 2.5wt%, silicone oil 0.1wt%, dioctyl phthalate 0.1wt% ester, 0.1wt% epoxidized soybean oil, 0.2wt% antioxidant thiodiethylenebis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]. First put the above components and magnetic powder into a high-speed mixer and mix evenly, then fully knead the resulting mixture with a belt-pressure kneader, then put the resulting mixture on a calender to obtain a thin magnetic sheet with a thickness of 0.6 mm, and finally Laminate three layers of thin magnetic sheets, compress and maintain the shape at 160°C under a pressure of 8 MPa for 15 minutes, and finally obtain a magnetic sheet with a thickness of 1.0 mm. The specific parameters are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com