Multi-strain composite microorganism feed additive and preparation method thereof

A technology of compound microorganisms and feed additives, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of decreased production performance, high morbidity and even mortality, and diarrhea of animals, so as to eliminate adverse reactions, improve the breeding environment, Growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The multi-species compound microbial feed additive of the present invention comprises the following components by weight:

[0040] Bacillus 29.2%, Enterococcus faecalis 16.3%, Saccharomyces cerevisiae 0.23%, Mannan oligosaccharide 8%, Small peptide preparation 3%, Vitamin 3%, Sulfate 6.08%, Potassium iodide 0.27%, Sodium selenite 0.22%, Stone powder 33.7% %.

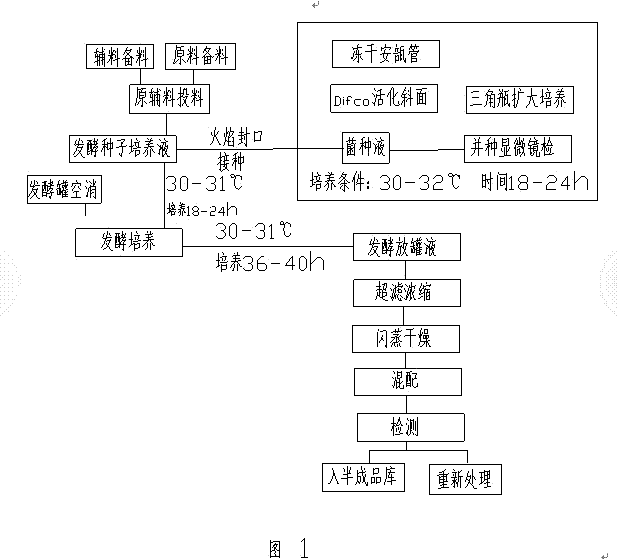

[0041] as attached figure 1 As shown, the above raw materials are sequentially subjected to liquid submerged fermentation and fixed closed fermentation to prepare the multi-strain compound microbial feed additive. The culture condition of the liquid submerged fermentation is: culture at 30-32°C for 18-24h; the culture condition of the fixed and closed fermentation is: culture at 30-31°C for 36-40h.

Embodiment 2

[0043] The multi-species compound microbial feed additive of the present invention comprises the following components by weight:

[0044] Bacillus licheniformis 12.5%, Bacillus lateralis 6.7%, Bacillus subtilis 10%, Enterococcus faecalis 16.3%, Saccharomyces cerevisiae 0.23%, mannan oligosaccharide 8%, small peptide preparation 3%, vitamin A 1.5%, vitamin D 1 %, vitamin E 0.5%, copper sulfate 0.5%, zinc sulfate 1.3%, ferrous sulfate 2.5%, manganese sulfate 1.3%, cobalt sulfate 0.48%, potassium iodide 0.27%, sodium selenite 0.22%, stone powder 33.7%.

[0045] as attached figure 1 As shown, the above raw materials are sequentially subjected to liquid submerged fermentation and fixed closed fermentation to prepare the multi-strain compound microbial feed additive. The culture condition of the liquid submerged fermentation is: culture at 30-32°C for 18-24h; the culture condition of the fixed and closed fermentation is: culture at 30-31°C for 36-40h.

Embodiment 3

[0047] The multi-species compound microbial feed additive of the present invention comprises the following components by weight:

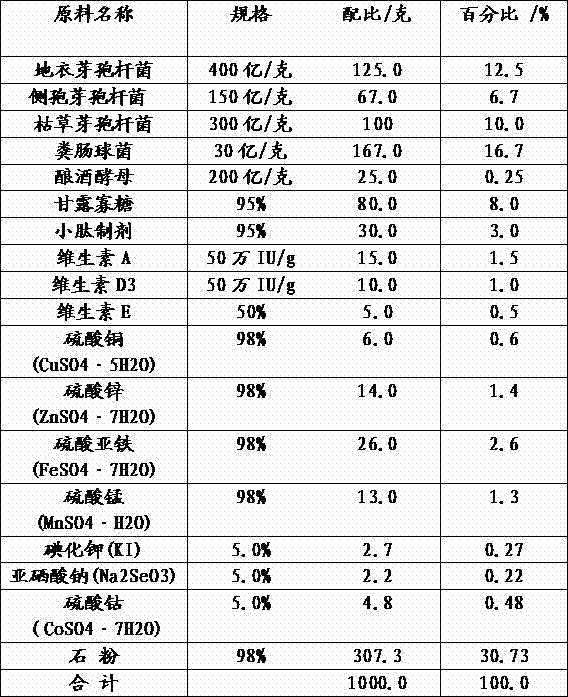

[0048] 40 billion / gram of Bacillus licheniformis 12.5%, 15 billion / gram of Bacillus lateralis 6.7%, 30 billion / gram of Bacillus subtilis 10%, 3 billion / gram of Enterococcus faecalis 16.3%, 20 billion / gram of Saccharomyces cerevisiae 0.23%, 95% mannan oligosaccharide 8%, 95% small peptide preparation 3%, 500,000 IU / g vitamin A 1.5%, 500,000 IU / g vitamin D 1%, 50% vitamin E 0.5%, 98% copper sulfate 0.5%, 98% zinc sulfate 1.3%, 98% ferrous sulfate 2.5%, 98% manganese sulfate 1.3%, 5% cobalt sulfate 0.48%, 5% potassium iodide 0.27% , 5% sodium selenite 0.22%, 98% stone powder 33.7%. as attached figure 1 As shown, the above raw materials are sequentially subjected to liquid submerged fermentation and fixed closed fermentation to prepare the multi-strain compound microbial feed additive. The culture condition of the liquid submerged fermentation is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com