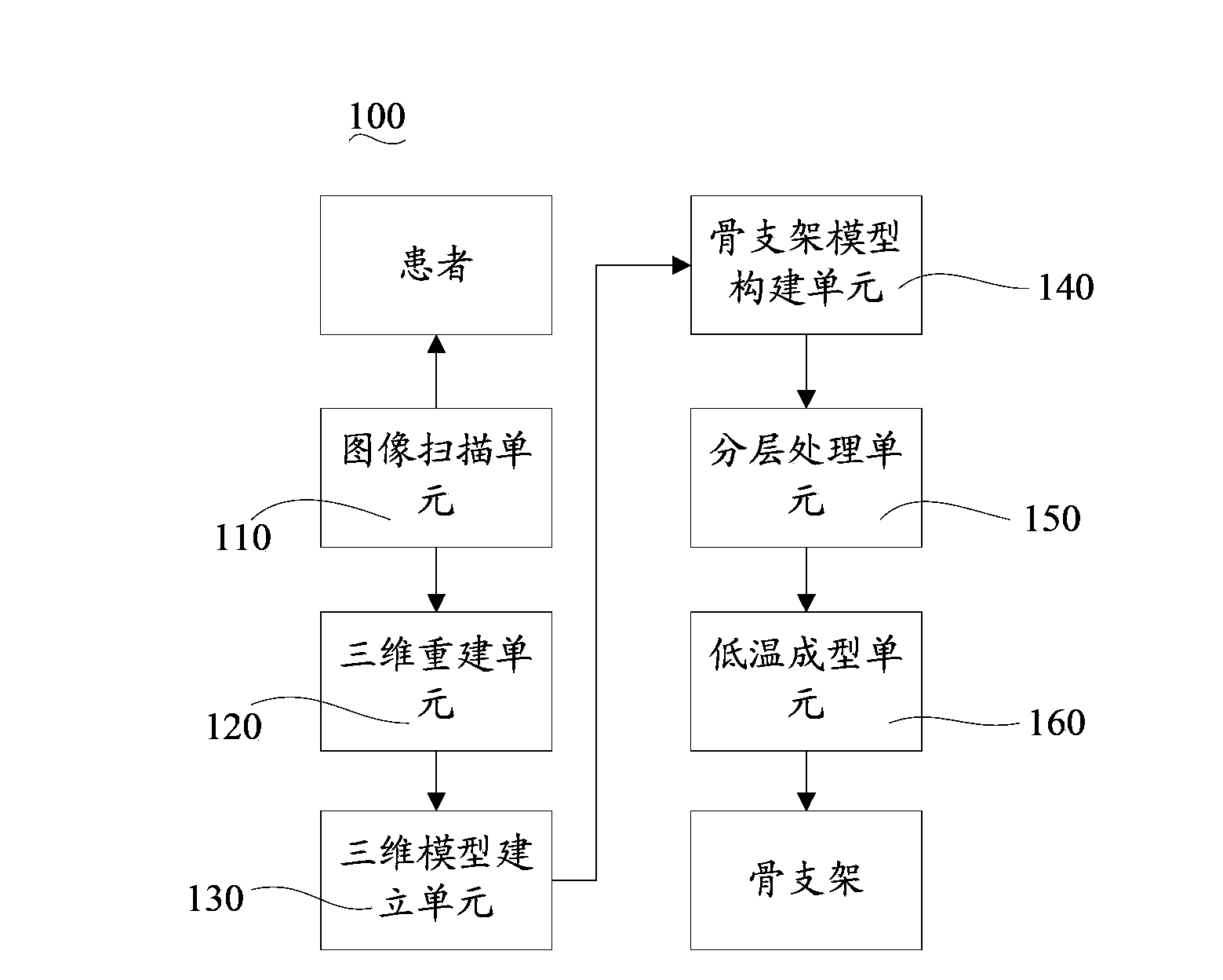

Bone scaffold forming system

A bone scaffold and model technology, applied in the field of biomedical tissue engineering, can solve the problem of lack of individual matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Through CT scanning of the necrotic part of the femoral head of the patient, the scanning interval is 0.70mm, and the two-dimensional CT image data is obtained, which is stored in the U disk in dicom format; the data is read, segmented and three-dimensionally reconstructed with Mimics software; extracted The grayscale threshold range for the distal femur was 769-1023. After the three-dimensional defect part model is established, the software mirror function and transparency function are used to cut and separate along the overlapped edge contour line, extract the three-dimensional restoration model, and generate an STL format file.

[0038] 2. Read the above files with Solidworks software, optimize the macrostructure of the prosthetic model and perform hierarchical processing, and output the files in CLI format.

[0039] 3. Prepare material solution: weigh 20g of polyglycolic acid-lactic acid copolymer, 5g of finely ground hydroxyapatite, and 5g of icariin according to...

Embodiment 2

[0044] 1. Through CT scanning of the patient's bone defect, the scanning interval is 0.75mm, and the two-dimensional CT image data is obtained, which is stored in the U disk in dicom format; the data is read, segmented and three-dimensionally reconstructed with Mimics software; the proximal tibial bone is extracted The grayscale threshold range at the end is 567-2014. After the three-dimensional defect part model is established, the software mirror function and transparency function are used to cut and separate along the overlapped edge contour line, extract the three-dimensional restoration model, and generate an STL format file.

[0045] 2. Read the above files with Solidworks software, optimize the macrostructure of the prosthetic model and perform hierarchical processing, and output the files in CLI format.

[0046] 3. Preparation of material solution: Weigh 20g of polylactic acid, 10g of finely ground calcium sulfate, and 5g of icariin according to mass percentage, put t...

Embodiment 3

[0051] 1. Through CT scanning of the patient's bone defect, the scanning interval is 0.65mm, and the two-dimensional CT image data is obtained, which is stored in the U disk in dicom format; the data is read, segmented and three-dimensionally reconstructed with Mimics software; the proximal tibial bone is extracted The grayscale threshold range at the end is 567-2014. After the three-dimensional defect model is established, use the software mirror function and transparency function to cut and separate along the overlapped edge contour line, extract the restoration model, and generate an STL format file.

[0052] 2. Read the above files with Solidworks software, optimize the macrostructure of the prosthetic model and perform hierarchical processing, and output the files in CLI format.

[0053] 3. Prepare the material solution: weigh 20g of polyglycolic acid, 1 part of finely ground tricalcium phosphate powder, 5g of icariin according to the mass percentage, put the above mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com