Preparation method for cerium-doped barium strontium titanate (BST) thin film

A strontium barium titanate thin film and cerium doping technology, applied in the field of functional materials, can solve the problems of lack of sol, precipitation, deterioration of BST thin film structure and dielectric properties, etc., and achieve low leakage current density and low dielectric loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

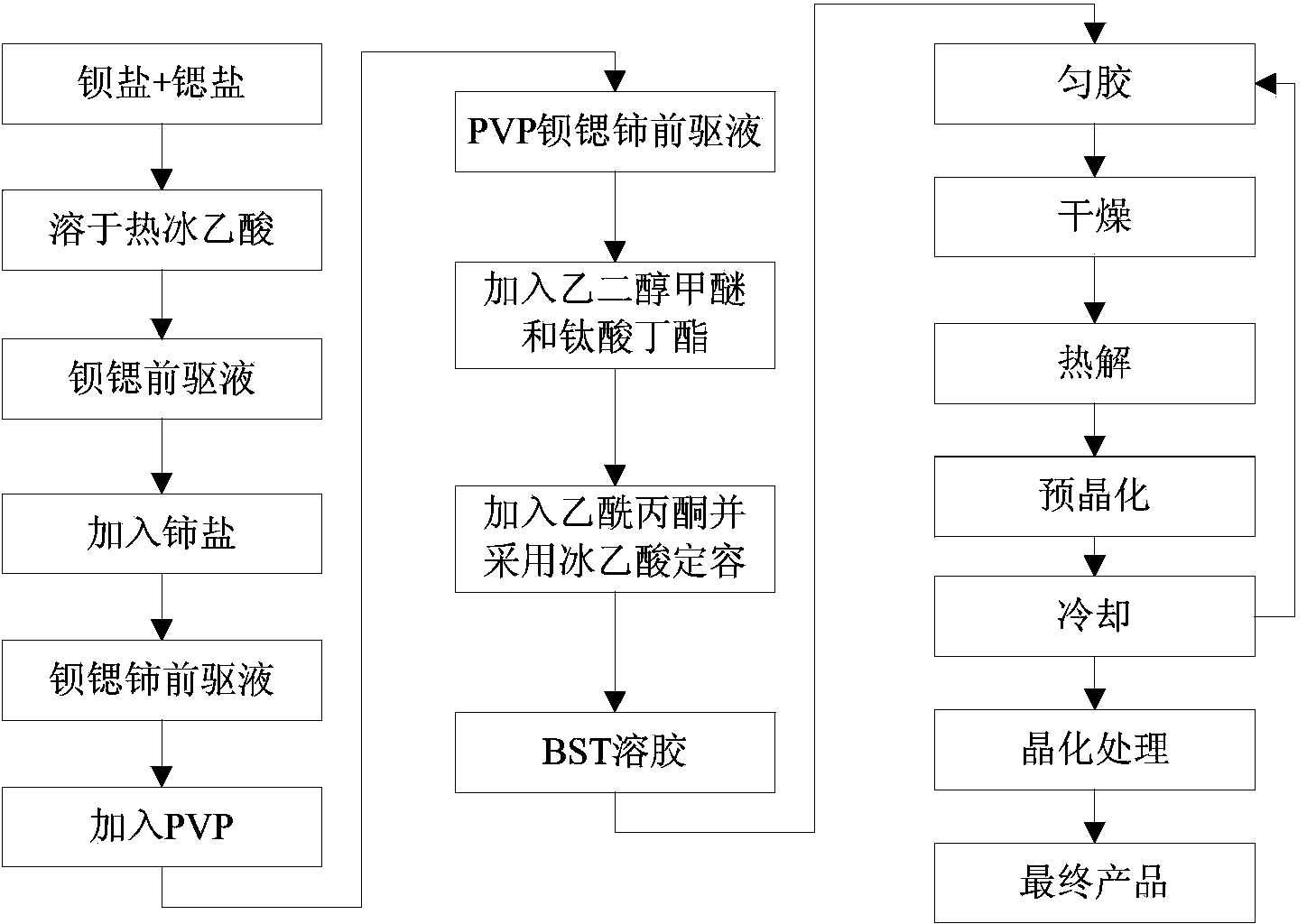

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: take cerium acetate as dopant to prepare 6 layers of Ba with cerium doping concentration of 1% 0.6 Sr 0.4 TiO 3 film

[0031] Step 1: Weigh barium acetate, strontium acetate and butyl titanate 0.012, 0.008 and 0.02 moles respectively according to the atomic molar ratio of Ba, Sr and Ti 0.6:0.4:1; add barium acetate and strontium acetate to 250-300 ml A barium strontium precursor solution is formed in a beaker of hot glacial acetic acid; add cerium acetate with 1% Ti atomic moles, and stir for 25 to 30 minutes to form a barium strontium cerium precursor; then add 0.6% Ti atomic moles PVP and stir for 20 to 30 minutes Minutes later, a PVP barium strontium cerium precursor solution was formed.

[0032] Step 2: Add 80-100 ml of ethylene glycol methyl ether to the PVP barium strontium cerium precursor solution and stir for 15-20 minutes, then add butyl titanate, and stir for 25-30 minutes to form a cerium-doped BST precursor solution.

[0033] Step 3: Add 8...

Embodiment 2

[0040] Embodiment 2: Prepare 6 layers of Ba with a cerium doping concentration of 20% using cerium acetate as a dopant 0.6 Sr 0.4 TiO 3 film

[0041] The implementation steps are as follows:

[0042] It is basically the same as "Steps of Example 1", except that "1%" in Step 1, Step 3 and Step 5 is replaced with "20%".

[0043] Similarly, to prepare other doping concentrations such as "0%" cerium-doped Ba 0.6 Sr 0.4 TiO 3 thin film or pure Ba 0.6 Sr 0.4 TiO 3 Thin film, only need to delete "add 1% Ti atomic mole cerium acetate, stir for 25-30 minutes to form barium strontium cerium precursor solution" in step 1, and at the same time delete the relevant "cerium" and "cerium doping" in the step and "Cerium doping concentration is 1%" can be deleted.

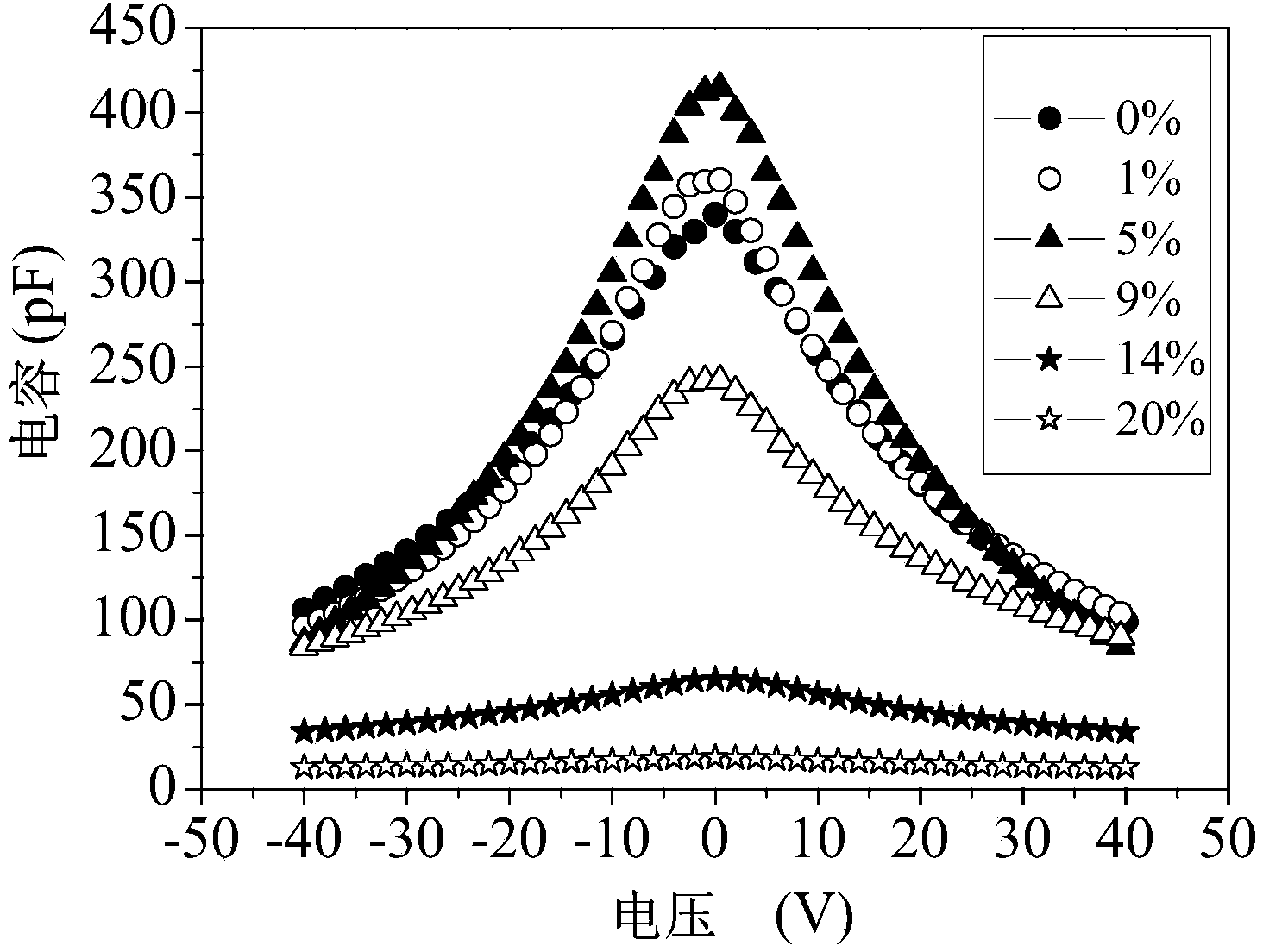

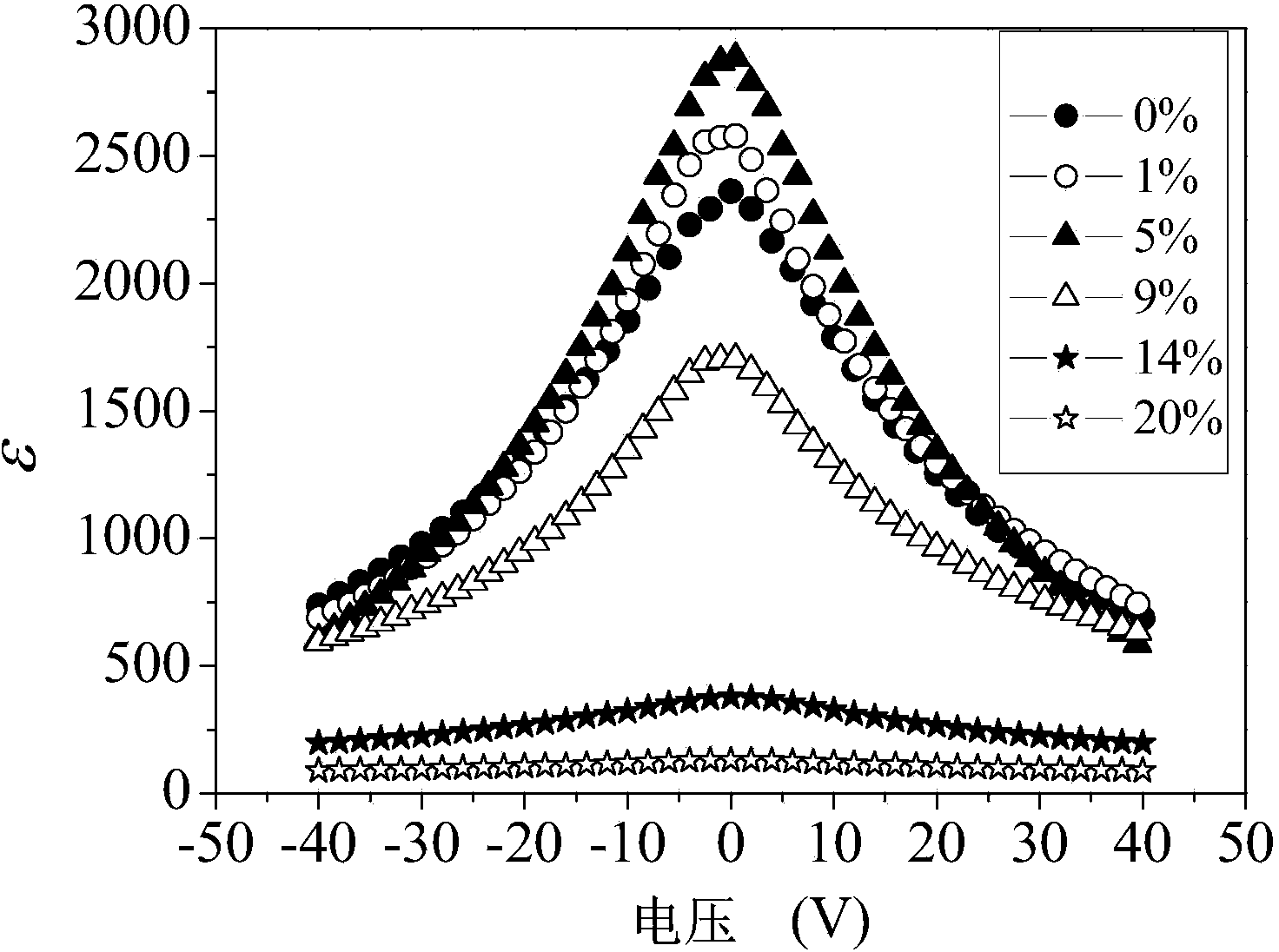

[0044] Examples 1 and 2 show that both BST sols and thin films with cerium acetate as dopant and cerium doping concentration of 0%-20% can be successfully prepared.

Embodiment 3

[0045] Embodiment 3: take cerium carbonate as dopant to prepare 6 layers of Ba with cerium doping concentration of 1% 0.6 Sr 0.4 TiO 3 film

[0046] The implementation steps are as follows:

[0047] It is basically the same as "the steps of Example 1", except that the relevant "cerium acetate" in step 1 is replaced by "cerium carbonate".

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap