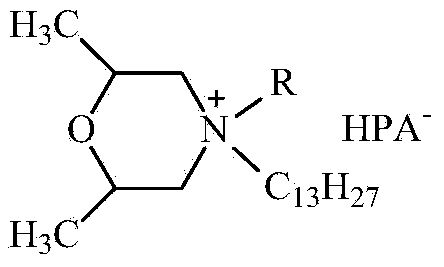

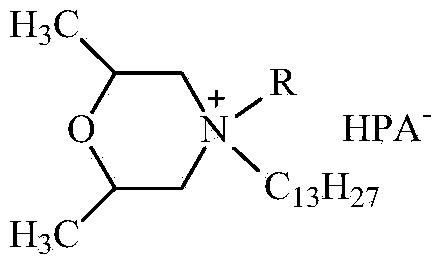

Heteropoly tridemorph quaternary ammonium salt as well as preparation method and application of quaternary ammonium salt

A technology of tridemorpholine and quaternary ammonium salt, which is applied in the field of preparation of tridemorpholine quaternary ammonium salt of heteropolyacid, can solve the problems of difficult recovery, lower use cost, poor solubility, etc., and achieve simplified production process and high activity , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of tridemorpholine quaternary ammonium salt

[0019] 44.6g (0.150mol) tridecylmorpholine and 20.6g (0.150mol) n-butyl bromide were stirred and reacted at 120°C for 48 hours to obtain a yellow semi-solid crude product, which was recrystallized from ethyl acetate to obtain tridecabromide as a pale yellow solid Morpholine n-butylammonium 63.2g, yield 96.9%.

Embodiment 2

[0020] Embodiment 2: Preparation of n-butyl trimorpholine ammonium phosphotungstic acid

[0021] 4.3g (0.010mol) n-butyl trimorphinium bromide and 28.8g (0.010mol) H 3 PW 12 o 40 Heat to reflux in 100mL of 1,2-dichloroethane, stir the reaction, use the suction device to absorb the hydrogen bromide generated, until no hydrogen bromide gas is generated, distill off the solvent to obtain 32.3g of milky white n-butyl phosphotungstic acid Trimorpholine ammonium salt, 100% yield.

[0022] The assay result of gained phosphotungstic acid n-tridemorpholine quaternary ammonium salt:

[0023] H NMR spectrum ( 1 H NMR, 300MHz, D 2 O) δ3.67-3.61(m, 2H), 3.52-3.49(m, 4H), 3.24-3.22(m, 4H), 1.34-1.32(m, 22H), 1.73(m, 4H), 1.21(d , J=7.2Hz, 6H), 0.97(t, J=7.2Hz, 3H), 0.96(t, J=7.2Hz, 3H).

[0024] Fourier transform infrared spectrum (potassium bromide tablet): 3404cm -1 (broad front) is the stretching vibration peak of H-O bond; 2959cm -1 、2873cm -1 It is the stretching vibration pe...

Embodiment 3

[0025] Embodiment 3: the preparation of epoxidized soybean oil

[0026] Install an electric mixer and a reflux condenser on a 250mL three-necked bottle, add 100.0g soybean oil (130 iodine value, 0.50 acid value), 2.0g n-butyltridecmorpholine ammonium phosphotungstic acid catalyst to the bottle, and control the reaction temperature 55°C, under stirring, slowly add 65mL of 30% hydrogen peroxide dropwise through the constant pressure dropping funnel. Determination, the epoxy value is 6.3%, the iodine value is 4.25g / 100g, and the acid value is 0.35mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com