Edible nano-peanut protein composite film and preparation process thereof

A peanut protein and preparation technology, applied in the biological field, can solve the problems of underutilization and waste of resources, and achieve the effects of reduced water vapor permeability and swelling degree, improved mechanical strength and water resistance, and reasonable compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation technology of edible nano-peanut protein composite film, it comprises the steps:

[0028] 1) Preparation of peanut protein isolate:

[0029] Take a certain amount of peanut protein powder, add water to dissolve according to the ratio of material to liquid 1:10 (kg / L), adjust the pH of the solution to 8.5, and stir at a constant temperature at 35°C for 1 hour, then centrifuge at 3000rpm for 15 minutes, and take the supernatant solution; adjust the pH of the supernatant to 4.5, centrifuge at 3000rpm for 15 minutes, collect the precipitate, and freeze-dry to obtain peanut protein isolate;

[0030] 2) Preparation of nano-peanut protein:

[0031] Prepare a peanut protein isolate solution with a concentration of 6% (add 6g to 100ml of water), adjust the pH of the solution to 8.5, let it stand at room temperature for 1 hour, and then add absolute ethanol drop by drop to the solution until the ethanol and water in the solution The volume ratio is 4:1, th...

Embodiment 2

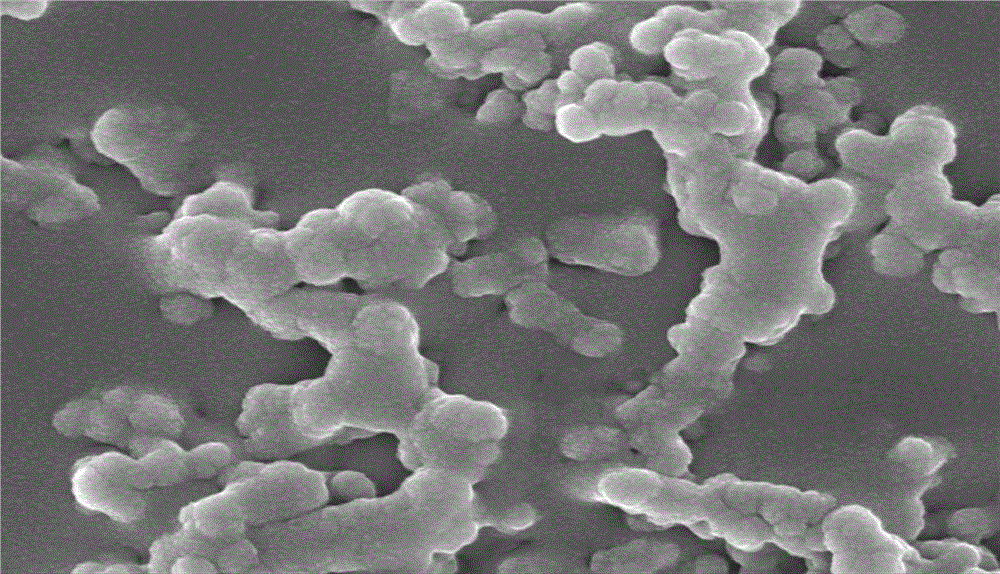

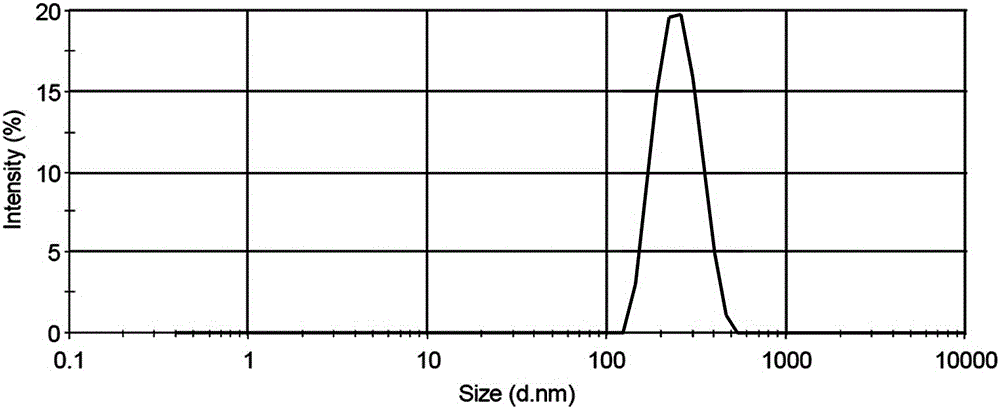

[0037] The analysis of nano peanut protein structure prepared by the present invention

[0038] figure 1 with figure 2 They are the scanning electron microscope image and particle size distribution graph of nano-peanut protein respectively, from which it can be seen that the nano-protein particles prepared by the present invention are spherical, have a consistent structure and smooth surface; the particle size distribution of nano-protein particles is from 150nm to 500nm, mainly The distribution is around 200nm, reaching the nanometer level, and the distribution is relatively uniform.

Embodiment 3

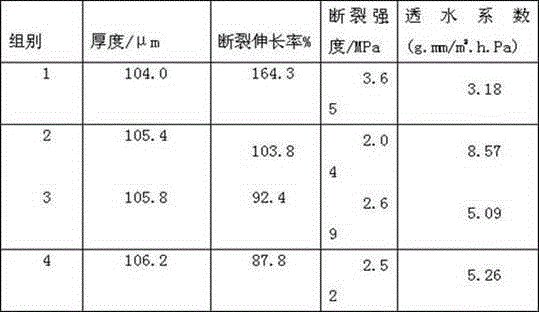

[0040] Performance testing and influencing factors:

[0041] 1. The influence of nano-corn starch solution on the mechanical strength and water resistance of peanut protein composite film, see Table 1, wherein, it is divided into four groups: Group 1 is Example 1 of the present invention; Group 2: Refer to Example 1, But no nano-corn starch solution was added; Group 3: referring to Example 1, adding corn starch (untreated); Group 4: referring to Example 1, adding pea starch (untreated).

[0042] Table 1

[0043]

[0044] Conclusion: In the present invention, by adding an appropriate amount of nano-corn starch, both the mechanical strength and the water-blocking performance are greatly improved.

[0045] 2. In the present invention, the water vapor permeability and swelling degree of the composite membrane are greatly reduced by adding chitosan and agar. Compared with the control group without adding chitosan and agar, we unexpectedly found that the water vapor permeability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com