Heat preservation transformation technology of clay brick wall body

A brick wall and clay technology, applied in the direction of walls, building construction, building maintenance, etc., can solve the problems of low wall thermal insulation performance, low land utilization rate, damage, etc., to achieve improved thermal insulation performance, high added value of planting, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

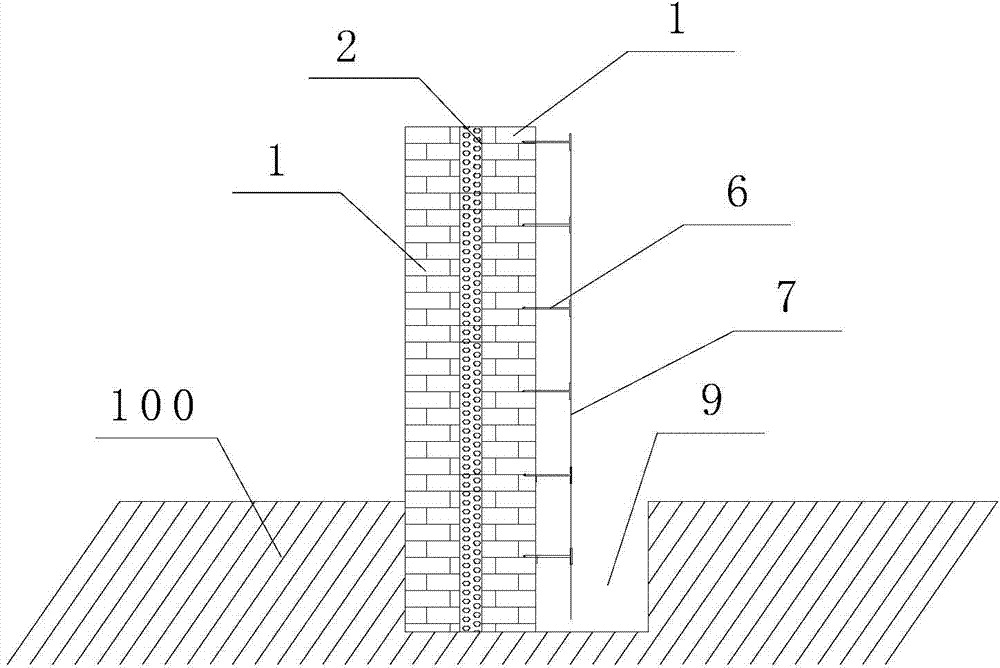

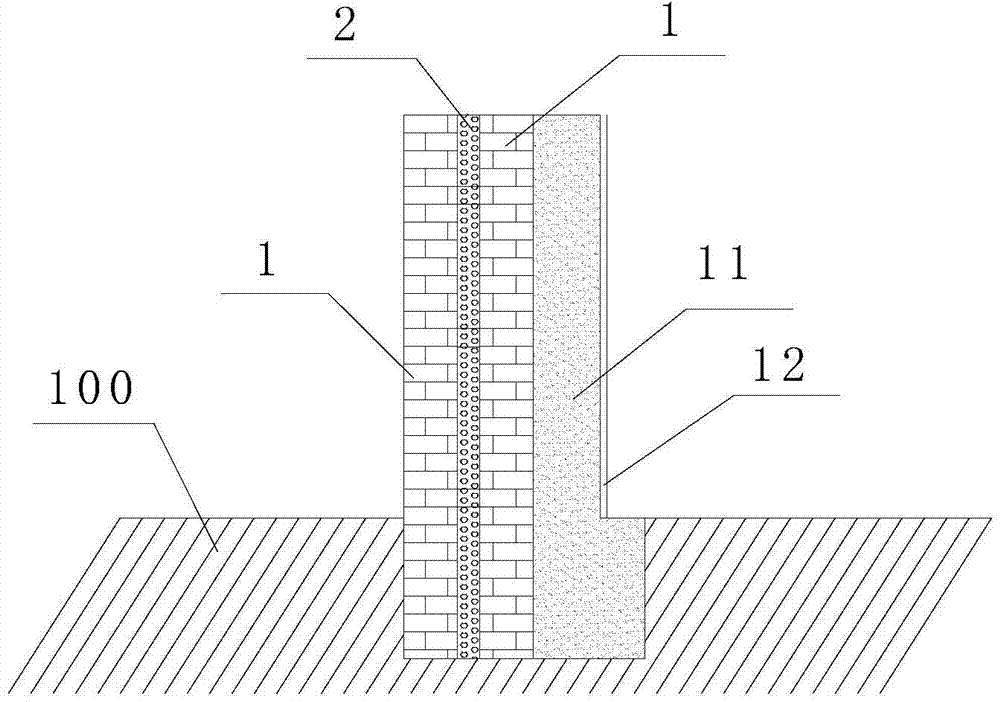

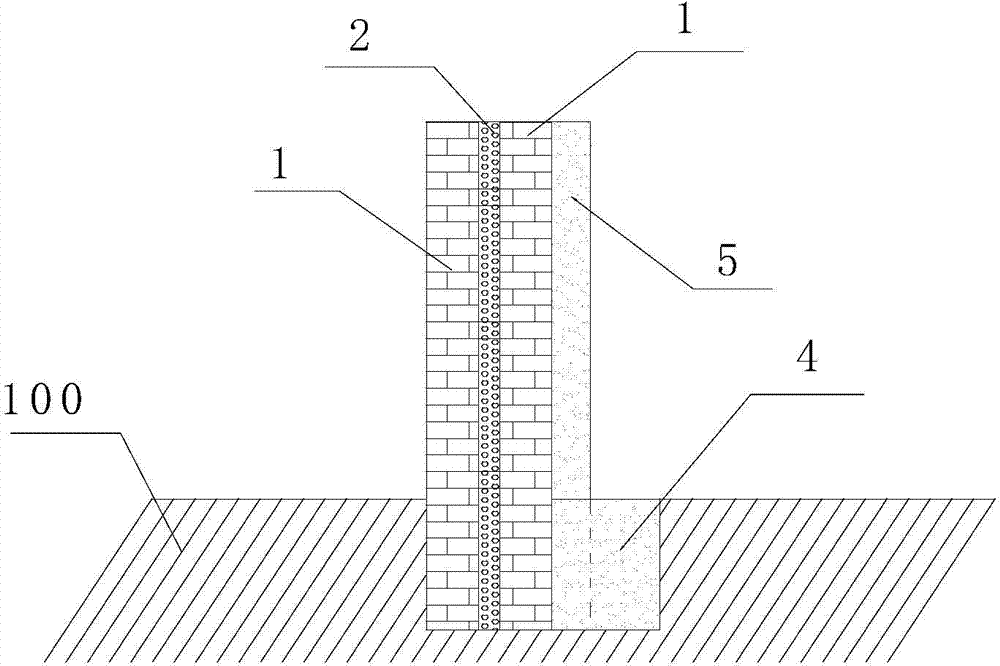

[0033] Please refer to figure 1 and figure 2 , wherein the existing clay brick wall includes clay brick 1 and polystyrene board 2 sandwiched between clay bricks 1, polystyrene board 2 is used to improve its thermal insulation capacity, obviously, as the basis, the clay brick wall It should be penetrated into the soil to a certain depth within 100°.

[0034] The following combination figure 1 and figure 2 Illustrate the thermal insulation modification process of the clay brick wall body of an embodiment of the present invention, comprise the steps:

[0035] (1) Dig down along the outer wall surface of the clay brick wall, dig out the construction pit 9, the construction pit 9 is a strip shape along the foundation of the outer wall, so that the foundation is exposed, and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap