Nano-structure lithium manganate/lithium iron phosphate/carbon three-dimensional composite spherical powder material and preparation process thereof

A technology of structural lithium manganate and lithium iron phosphate, applied in the directions of nanotechnology, nanotechnology, structural parts, etc., can solve the problem of not realizing multi-phase nanocomposite, and achieve the effect of inhibiting the dissolution of Mn, good protection, and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

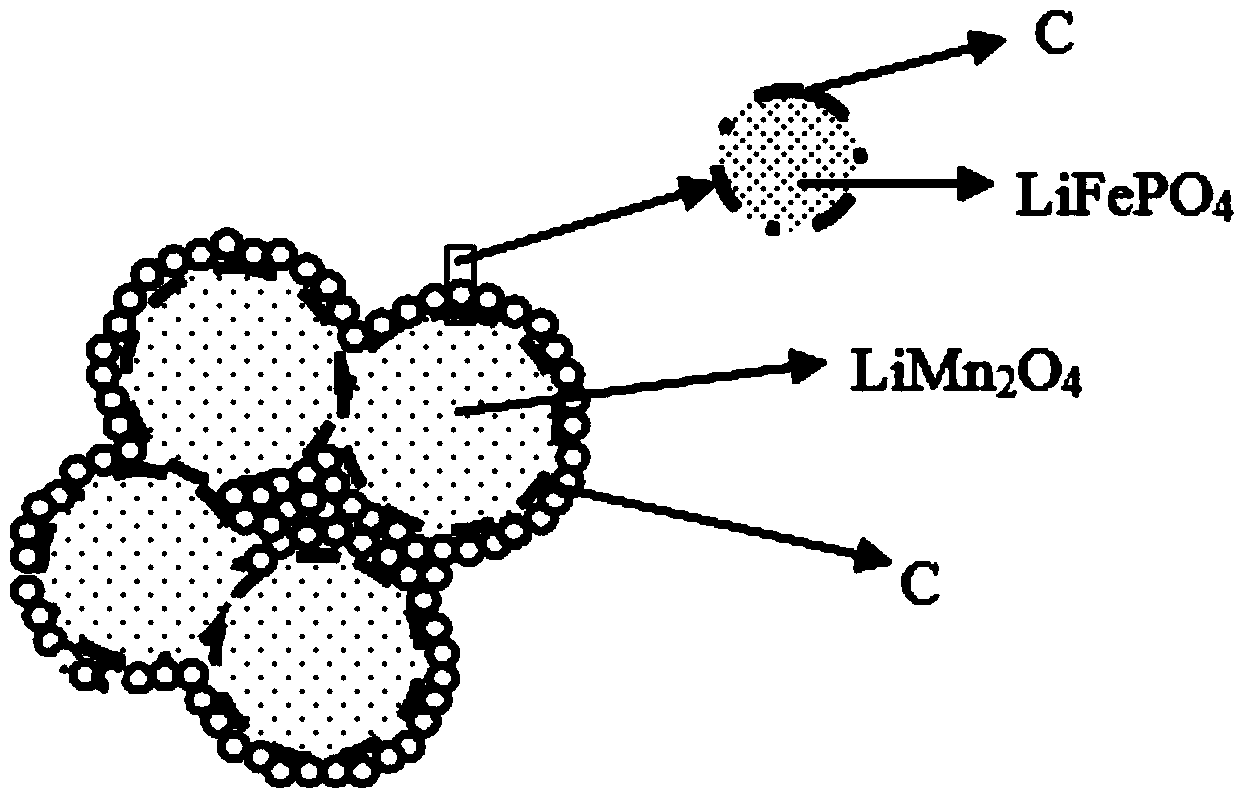

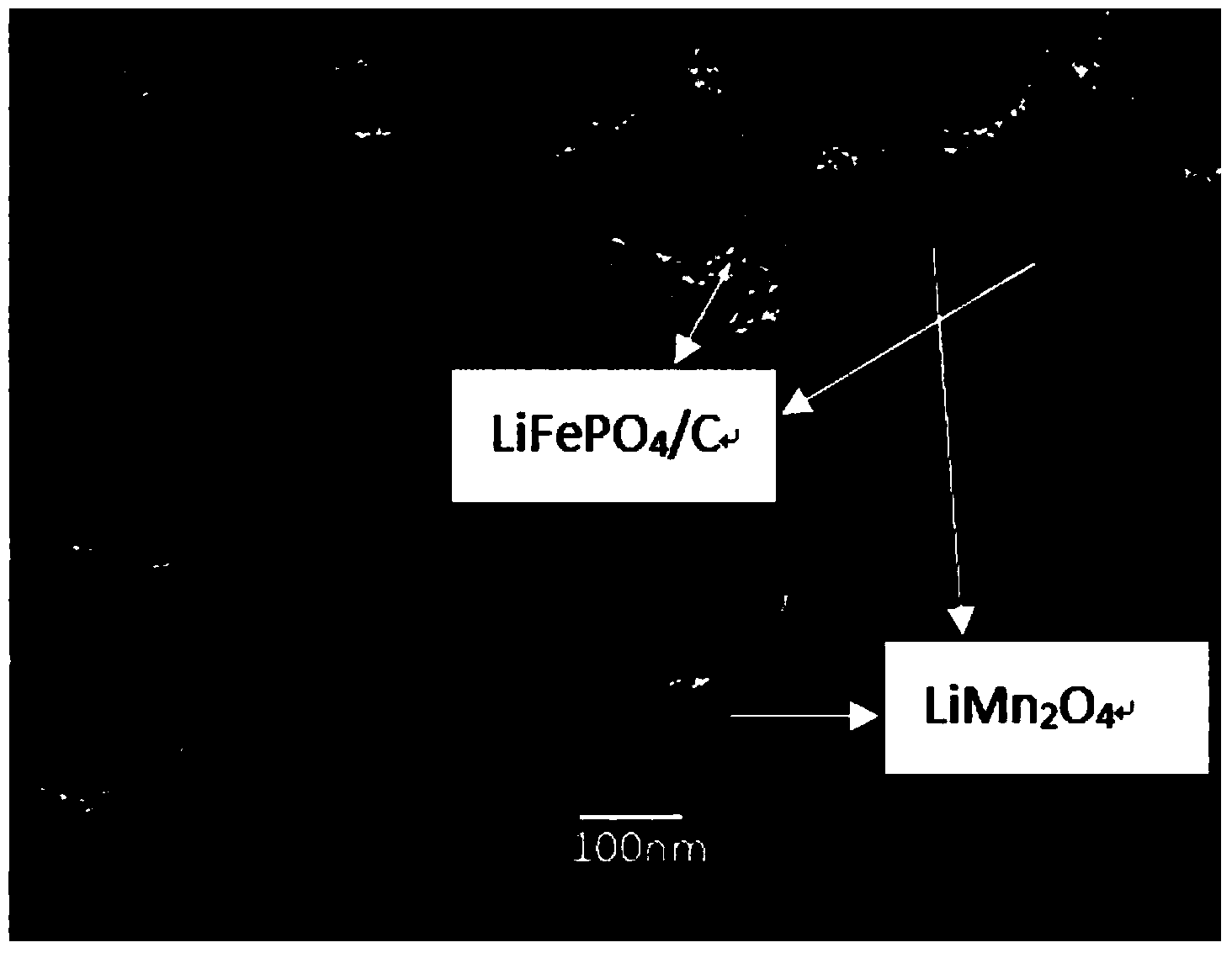

[0039] a kind of like figure 1 The nanostructured lithium manganate / lithium iron phosphate / carbon three-dimensional composite spherical powder material of the present invention is mainly composed of nanoporous lithium manganate, nanometer lithium iron phosphate and carbon three-phase, and has a spherical shape. The particle size of the three-dimensional composite spherical powder material is micron-scale, the particle size of the primary particles constituting the three-dimensional composite spherical powder material is nano-scale, and the nano-lithium iron phosphate and carbon are uniformly deposited on the surface of the microspheres and In the pores, the mass fractions of nanoporous lithium manganese oxide, nanometer lithium iron phosphate and carbon in the three-dimensional composite spherical powder material are 90%, 5% and 5%, respectively, that is, nanoporous lithium manganate, nanometer lithium iron phosphate and The mass ratio of carbon is controlled at 9:0.5:0.5. In...

Embodiment 2

[0048] a kind of like figure 1 The nanostructured lithium manganate / lithium iron phosphate / carbon three-dimensional composite spherical powder material of the present invention is mainly composed of nanoporous lithium manganate, nanometer lithium iron phosphate and carbon three-phase, and has a spherical shape. The particle size of the three-dimensional composite spherical powder material is micron-scale, the particle size of the primary particles constituting the three-dimensional composite spherical powder material is nano-scale, and the nano-lithium iron phosphate and carbon are uniformly deposited on the surface of the microspheres and In the pores, the mass fractions of nanoporous lithium manganese oxide, nanometer lithium iron phosphate and carbon in the three-dimensional composite spherical powder material are 50%, 45% and 5%, respectively, that is, nanoporous lithium manganate, nanometer lithium iron phosphate and The mass ratio of carbon is controlled at 5:4.5:0.5. I...

Embodiment 3

[0057] a kind of like figure 1The nanostructured lithium manganate / lithium iron phosphate / carbon three-dimensional composite spherical powder material of the present invention is mainly composed of nanoporous lithium manganate, nanometer lithium iron phosphate and carbon three-phase, and has a spherical shape. The particle size of the three-dimensional composite spherical powder material is micron-scale, the particle size of the primary particles constituting the three-dimensional composite spherical powder material is nano-scale, and the nano-lithium iron phosphate and carbon are uniformly deposited on the surface of the microspheres and In the pores, the mass fractions of nanoporous lithium manganese oxide, nanometer lithium iron phosphate and carbon in the three-dimensional composite spherical powder material are 70%, 27% and 3%, respectively, that is, nanoporous lithium manganate, nanometer lithium iron phosphate and The mass ratio of carbon is controlled at 7:2.7:0.3. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com