Engineering bacterium for highly expressing lipopeptide biosurfactant and application thereof

A technology of biological surface and engineering bacteria, applied in the field of biotechnology and biochemical industry, to achieve good industrial application prospects, increase production, and increase output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

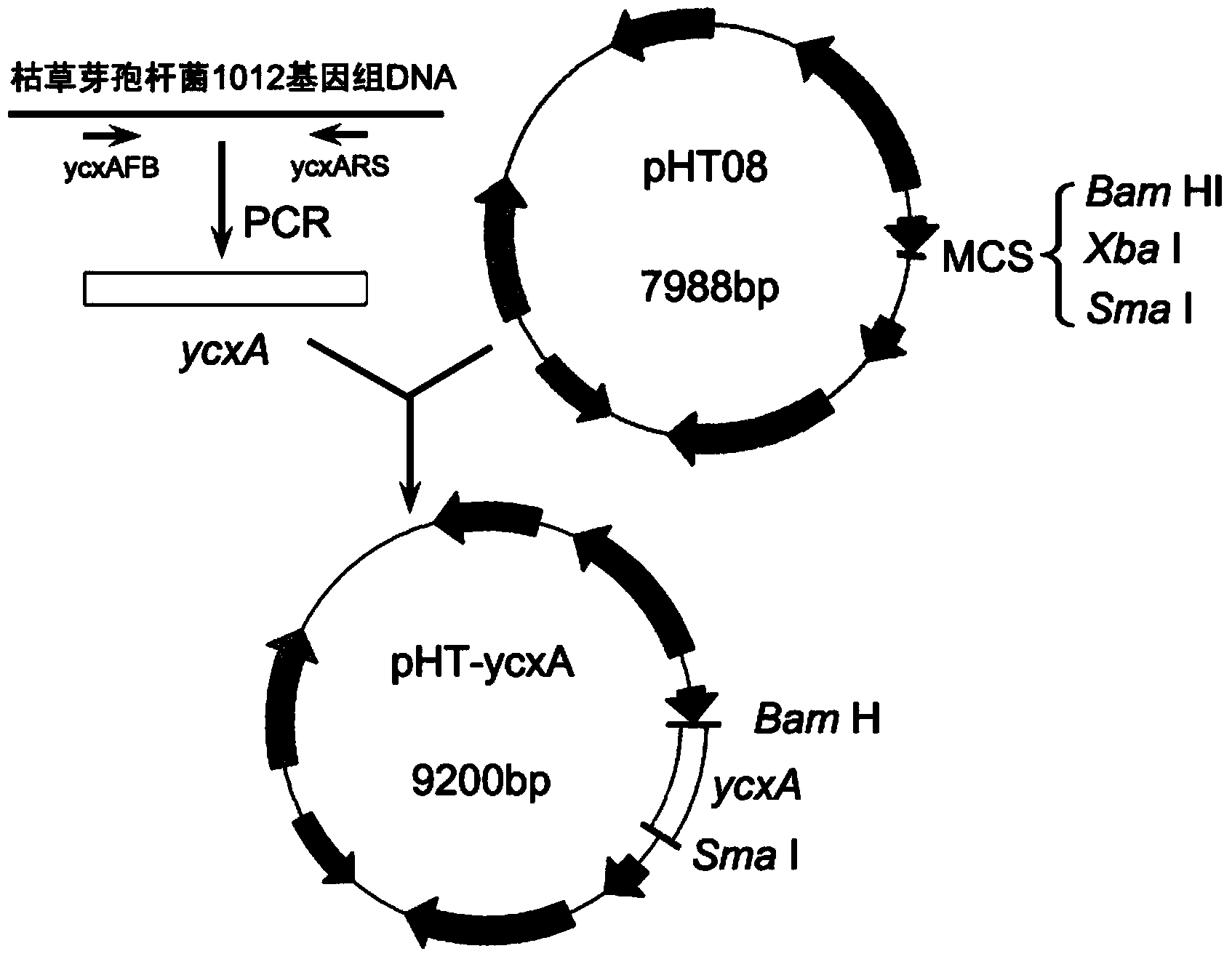

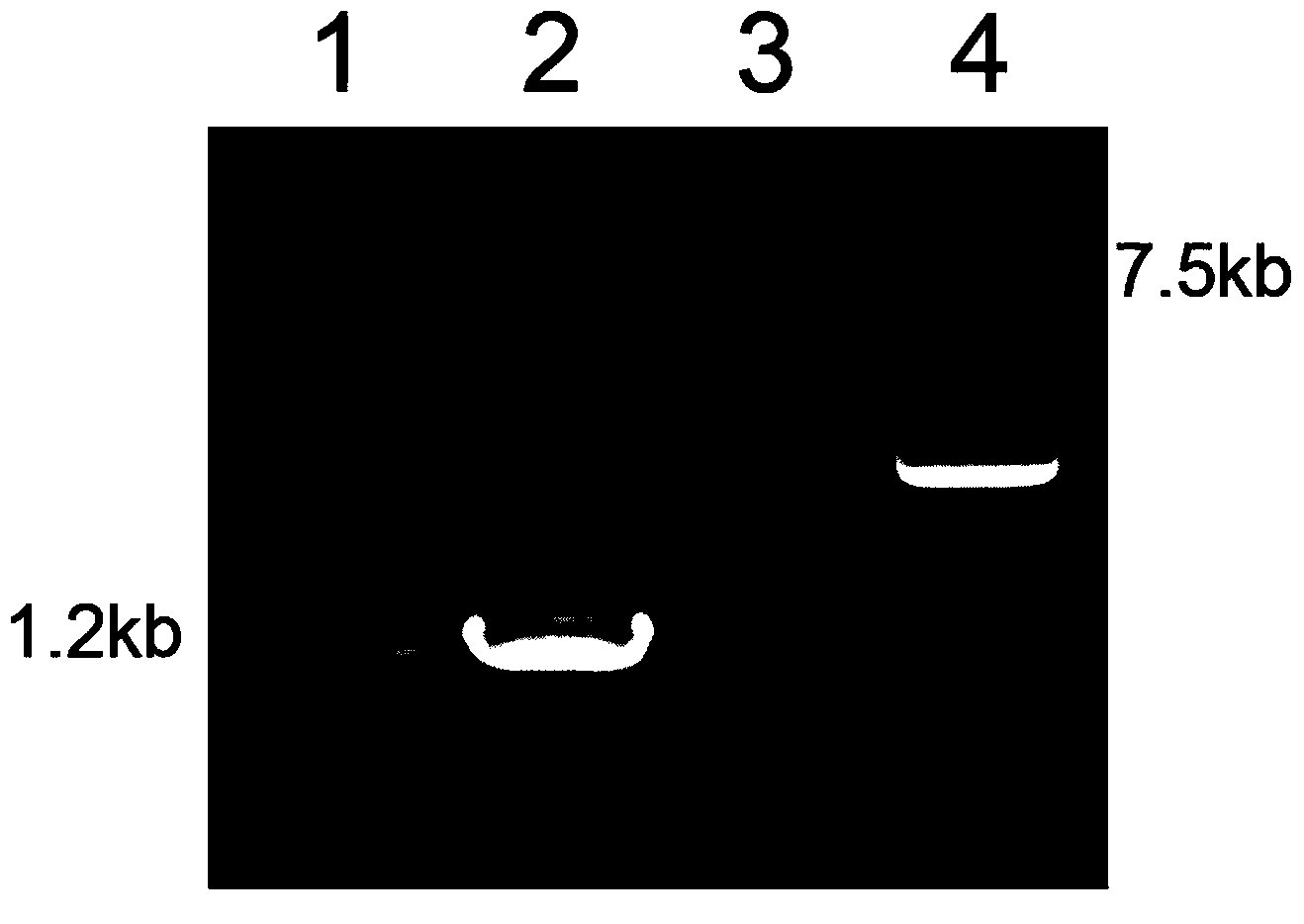

[0057] Construction of Bacillus subtilis-Escherichia coli shuttle plasmid carrying lipopeptide carrier protein gene ycxA

[0058] Pick a single colony of Bacillus subtilis 1012wt (purchased from MoBiTec), inoculate it in LB liquid medium, cultivate it for 16 hours at a temperature of 37°C and a shaker speed of 200 rpm, and centrifuge at 12,000 rpm for 5 minutes to collect the bacterial precipitate. Bacillus subtilis 1012wt genomic DNA was extracted with the Bacterial Genome Extraction Kit from Omega. Using the above obtained Bacillus subtilis 1012wt genomic DNA as a template, the upstream primer ycxAFB (sequence shown in SEQ ID No: 2) and the downstream primer ycxARS (sequence shown in SEQ ID No: 3) were used for PCR gene amplification. Primers were synthesized by Platinum Biotechnology (Shanghai) Co., Ltd., dissolved in sterile water, and diluted to 10 μM for use. The polymerase, buffer and dNTP used in PCR amplification were purchased from TaKaRa Company. The PCR amplifica...

Embodiment 2

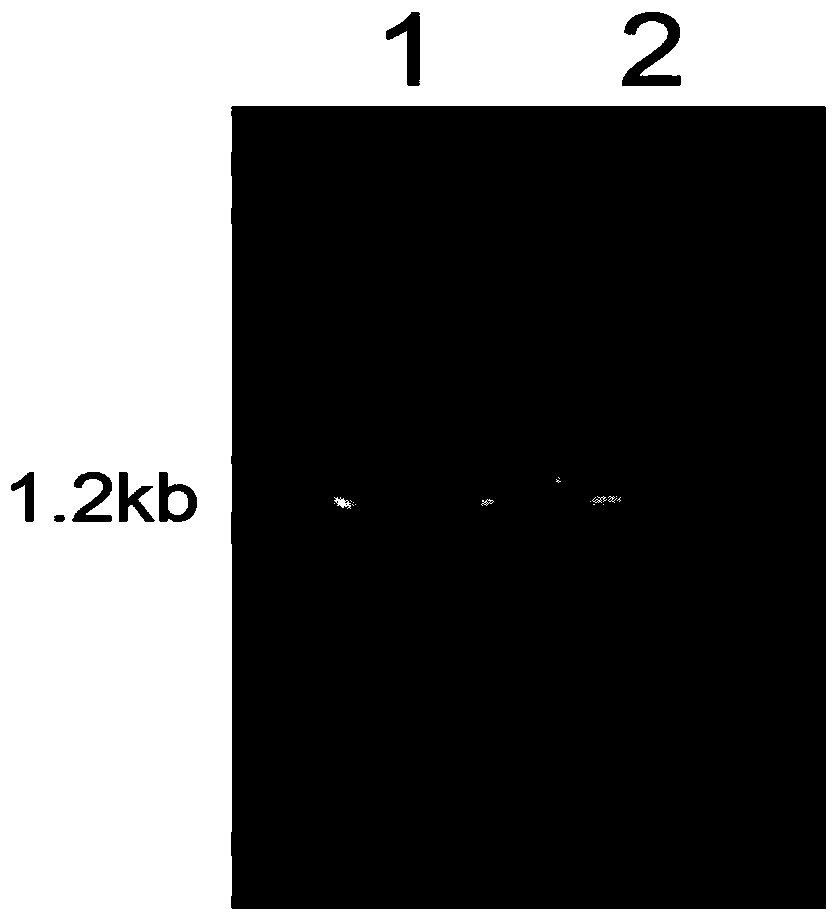

[0062] Construction of Genetic Engineering Bacteria Overexpressing Lipopeptide Carrier Protein YcxA

[0063] The Bacillus subtilis-Escherichia coli shuttle plasmid pHT-ycxA carrying the lipopeptide carrier protein gene ycxA constructed in Example 1 was transformed into competent cells of Bacillus subtilis THY-7 by electroporation to obtain an overexpressed lipopeptide carrier protein Genetic engineering strain TS589 of YcxA. Wherein, the preparation of Bacillus subtilis THY-7 competent cells adopts the method of Xue et al. (Journal of Microbiological Methods, 1999, 34:183-191). Add 2.5 μL of recombinant plasmid pHT-ycxA and 50 μL of Bacillus subtilis THY-7 competent cells to a 1.5 mL centrifuge tube, mix well, add a 0.1 cm electroporation cup, and ice-bath for 30 min; adjust the voltage of the electroporator to 1.25 kV, and turn the Put the cup into the electroporation instrument and press the electric shock button; after the electroporation, add 1mL recovery medium (see Xue ...

Embodiment 3

[0065] Production of lipopeptide surfactant—surfactin by using genetically engineered bacteria TS589

[0066] The overexpressed lipopeptide carrier protein ycxA genetically engineered bacterium TS589 obtained in Example 2 was inoculated in LB liquid medium (containing 5 μg / mL chloramphenicol), cultured at 37°C and 200 rpm for 16 hours, and inserted into the fermentation at a ratio of 5%. In the culture medium, cultivate at 37°C and 200 rpm for 4 hours, add IPTG (final concentration 1mM), and continue to cultivate for 24 hours to obtain lipopeptide-containing fermentation broth. Take 100 μL of the fermentation broth obtained in step 1, add 900 μL of deionized water, mix well, filter through a 0.22 μm filter membrane, and load the sample for HPLC analysis. The Shimadzu LC20A chromatographic system was used, the chromatographic column was ODS-SP250×4.6mm (GL Sciences), the mobile phase was acetonitrile:water:trifluoroacetic acid=93:7:0.1, the flow rate was 0.8mL / min, and the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com