A kind of preparation method of three-dimensional porous zno nano flake gas-sensing material and gas-sensing element

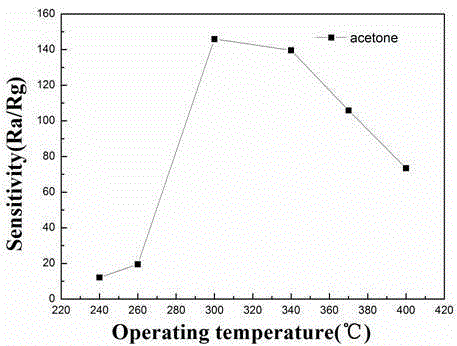

A technology of three-dimensional porous and gas-sensing materials, which is applied in the field of preparation of three-dimensional porous ZnO nanosphere gas-sensing materials and gas-sensing elements, can solve the problems of poor repeatability, low sensitivity and instability of acetone sensors, and achieve low operating temperature and high response - Fast recovery time, good selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

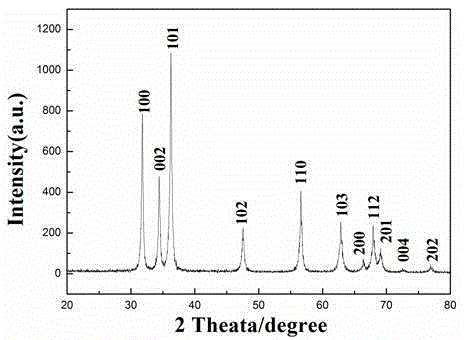

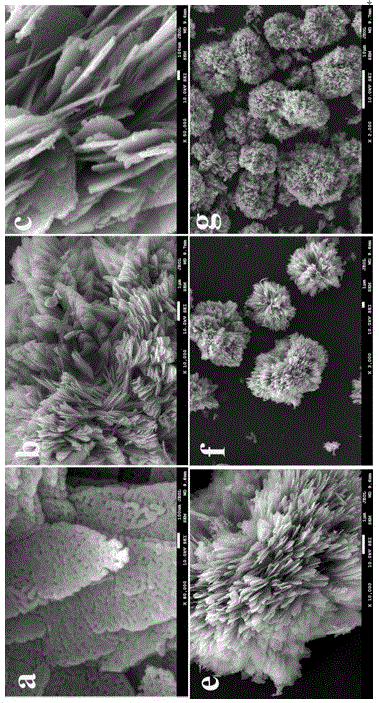

[0023] A preparation method of a three-dimensional porous ZnO nano-sphere gas-sensitive material. Firstly, a three-dimensional ZnO nano-sphere material is synthesized by a hydrothermal method. Into the mixed solution of deionized water and absolute ethanol, wherein the volume ratio of deionized water and absolute ethanol is 1:3 and the amount of deionized water required for every 1mmol dihydrate zinc chloride and 1mmol urea is 10~15ml , then add polyvinylpyrrolidone under stirring, the ratio of the amount of polyvinylpyrrolidone to zinc chloride dihydrate is 1.8~2:1, keep stirring for 30~40min, then transfer the mixed solution to the autoclave And put it into a drying box and raise the temperature to 180~200°C for 16~20h. After the reaction, wait for the reaction kettle to cool down to room temperature naturally, and centrifuge and wash the precipitate 3~5 times with a mixture of deionized water and absolute ethanol. Place it in a vacuum drying oven at 70°C for drying to obtai...

Embodiment 2

[0026] A kind of preparation method of three-dimensional porous ZnO nano flake gas-sensitive material, at first utilize hydrothermal method to synthesize three-dimensional ZnO nano flake material, the steps are as follows: accurately weigh 1mmol (0.1363g) of zinc chloride (ZnCl 2 2H 2 O) and 1mmol (0.6000g) of urea (CO(NH 2 ) 2 ), dissolve them into 10ml of deionized water and 30mL of absolute ethanol, form a uniform and stable solution under vigorous stirring, then add 0.2000g of polyvinylpyrrolidone (PVP) under stirring, and stir for 30min to All the solids were dissolved, and then the mixed solution was transferred to a polytetrafluoroethylene-lined autoclave, and placed in a drying oven to raise the temperature to 180°C for 16 hours. After the reaction, the autoclave was naturally cooled to room temperature, and the precipitate was used Deionized water and absolute ethanol were centrifuged and washed several times, and dried in a vacuum oven at 70°C to obtain a white pow...

Embodiment 3

[0029] A kind of preparation method of three-dimensional porous ZnO nano flake gas-sensitive material, at first utilizing hydrothermal method to synthesize three-dimensional ZnO nano flake material, the steps are as follows: dissolve 2mmol zinc chloride dihydrate and 2mmol urea into 20ml deionized water and 60ml In the mixed solution of absolute ethanol, add 3.6mmol polyvinylpyrrolidone under stirring, continue to stir for 40min until all solids are dissolved, then transfer the mixed solution to a high-pressure reactor and put it in a drying oven to heat up to 200°C for reaction After 16 hours, after the reaction, the reaction kettle was naturally cooled to room temperature, and the precipitate was centrifuged and washed 3 to 5 times with a mixture of deionized water and absolute ethanol, and dried in a vacuum drying oven at 70°C to obtain a white The powdery precursor is the three-dimensional ZnO nanosheet material; then the nanosheet material is calcined at 300°C for 2 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com