Preparing method of sodium-ion battery cathode material

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., to achieve high charge and discharge efficiency and energy efficiency, improve electrochemical activity, and have no environmental pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

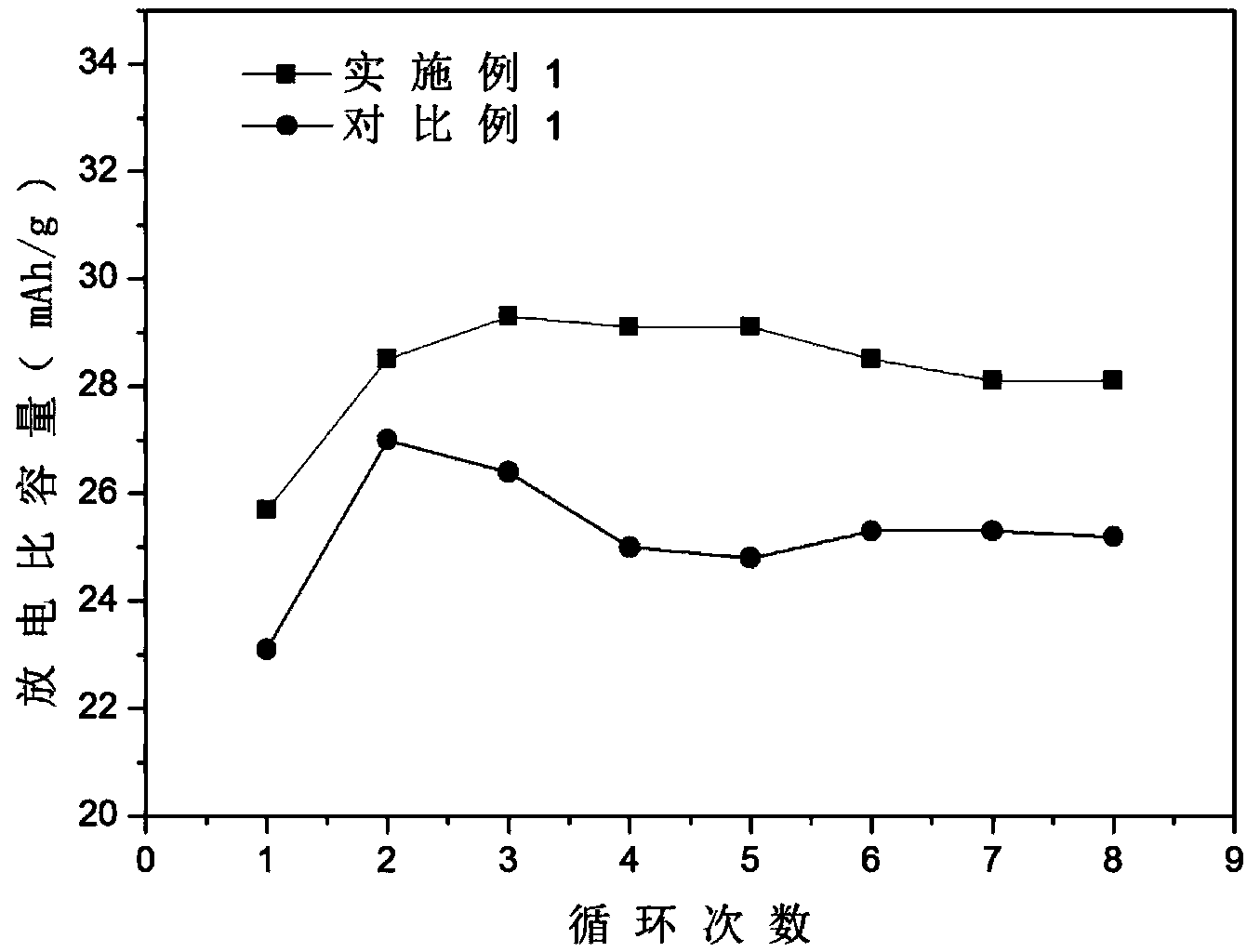

Examples

Embodiment 1

[0033] Add 23.32 g Na 2 CO 3 , 34.78 g MnO 2 and 50 ml of ethanol for ball milling for 6 hours to form a homogeneous slurry; then, transfer the slurry to a stainless steel tray, put it in an oven at 60°C for drying, and obtain a uniformly mixed raw material powder; then use a pressure of 10 MPa Press the raw material powder into a corundum crucible, raise the temperature to 900°C at a rate of 10°C / min, and keep it warm for 10 hours for sintering. After the sintering is completed, naturally cool to room temperature to obtain a black block sintered product.

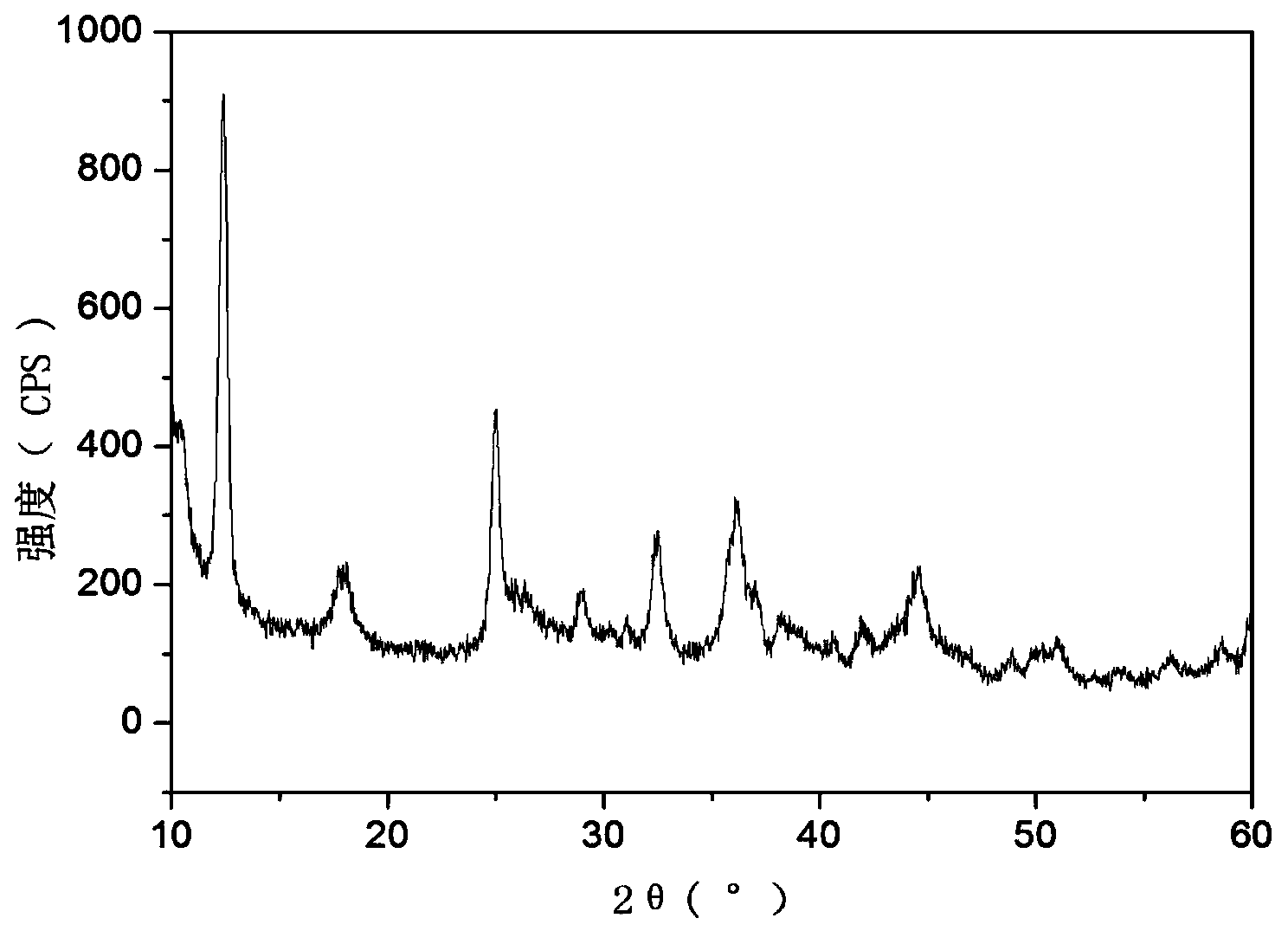

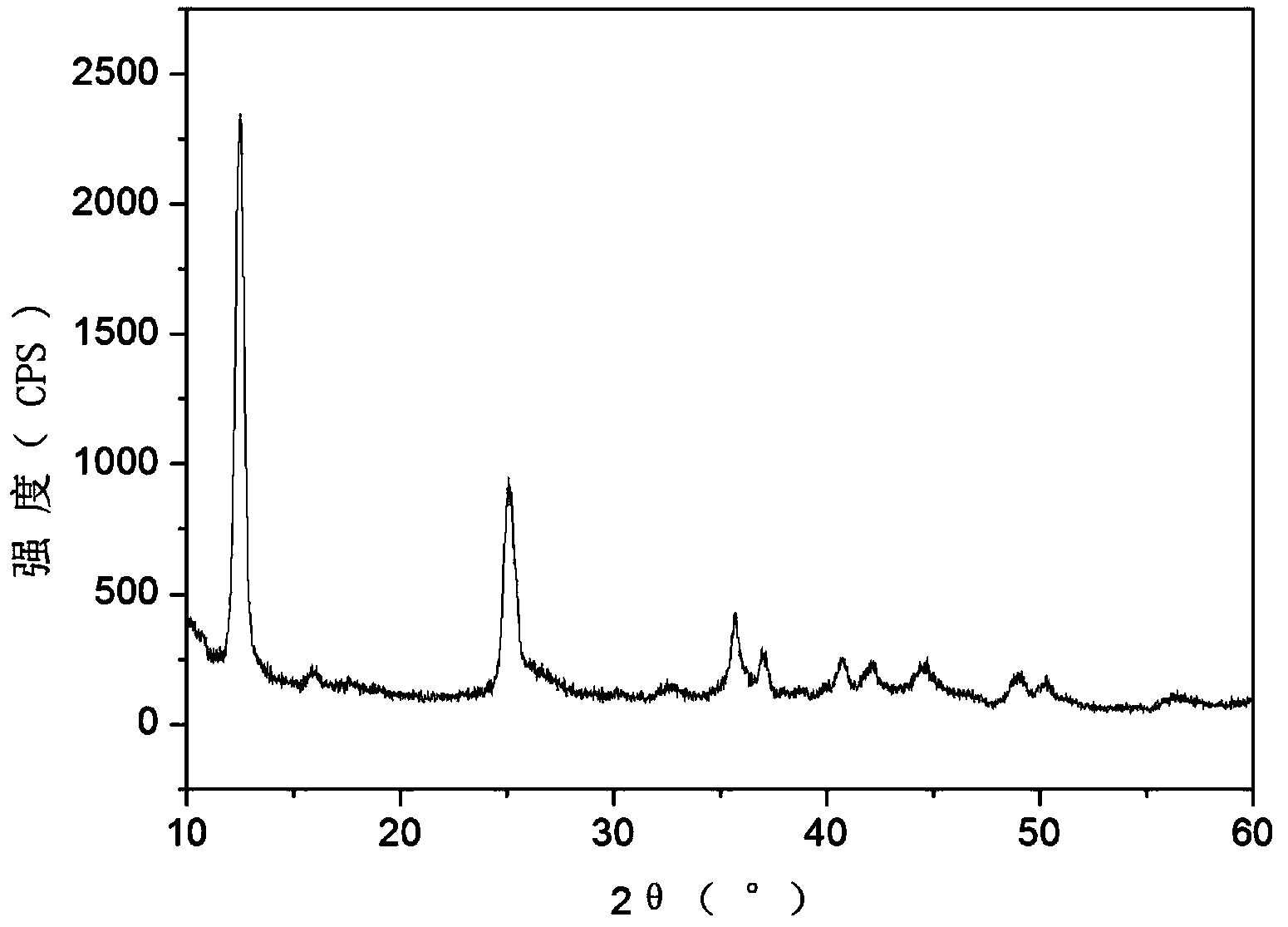

[0034] Grind and pulverize the obtained sintered product, add it to 200 mL of deionized water at 80°C for repeated washing-filtering 4 times, mechanically stir for 2 hours during the washing process, then wash-filtering once with 1:1 ethanol solution , and then dried in an oven at 80° C. to obtain the final product. see figure 1 , the final product obtained by XRD pattern analysis is a layered structure of hydrated sodi...

Embodiment 2

[0036] According to the ratio of Na:Mn molar ratio 1.1:1, 34.98 gNa 2 CO 3 and 45.76 g Mn 3 o 4 The dry powder is ground and mixed evenly, and then pressed into tablets with a pressure of 8 MPa, put into a corundum crucible, raised to 850°C at a rate of 5°C / min, and kept for 12 hours for sintering. After sintering, it is naturally cooled to room temperature to obtain Sintered product of black mass.

[0037] The obtained sintered product was ground and pulverized, added to 300ml of deionized water and repeatedly washed-filtered 3 times, mechanically stirred at room temperature for 3 hours during the washing process, and then vacuum-dried at 85°C for 10 hours to obtain the final product. see figure 1 , the final product obtained by XRD pattern analysis is a layered structure of hydrated sodium manganese base NaMnO 2 ·H 2 O. The specific surface area of the product is shown in Table 1; the performance index of the product used in the sodium ion battery is shown in Tab...

Embodiment 3

[0039] According to the ratio of Na:Mn molar ratio 2:1, 56.82 g Na 2 SO 4 and 34.78 g MnO 2 The dry powder was ball-milled and mixed evenly; after that, it was pressed into tablets with a pressure of 10 MPa, put into a corundum crucible, raised to 1000°C at a rate of 5°C / min, and kept for 6 hours for sintering. After sintering, it was naturally cooled to room temperature to obtain Sintered product of black mass.

[0040] Grind and pulverize the obtained sintered product, add it to 500ml, 85°C deionized water, wash and filter repeatedly 4 times, stir ultrasonically for 2 hours during the washing process, wash and filter once with 1:1 acetone solution, and then freeze Drying for 10 hours gave the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com