High-voltage lithium ion battery positive electrode material with spinel structure and preparation method thereof

A spinel structure, lithium-ion battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as high cost, low temperature, agglomeration, etc., and achieve easy industrial production, simple synthesis process, and material properties. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

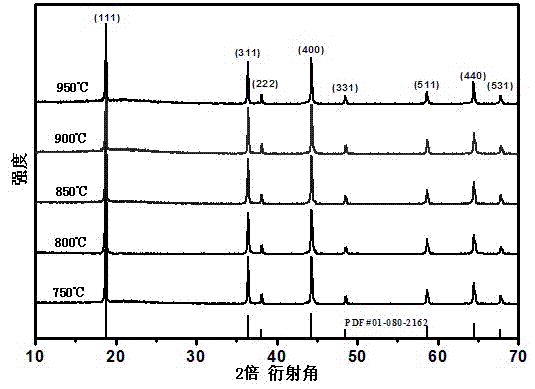

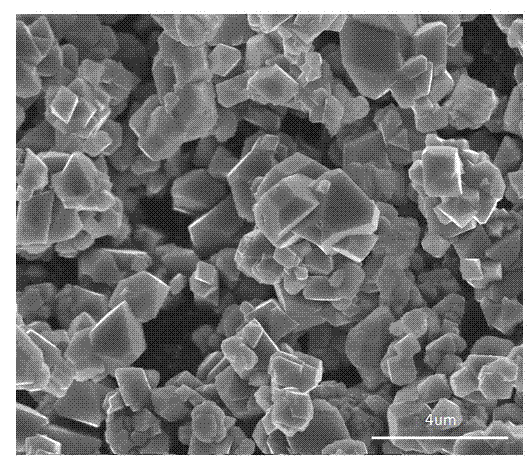

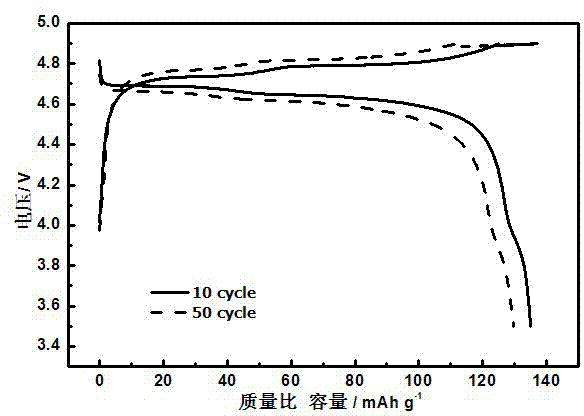

[0034] The stoichiometric ratio of manganese acetate and nickel acetate was added to deionized water and dissolved to prepare a solution a with a concentration of 0.5 mol / L. At the same time, an appropriate amount of oxalic acid was weighed to prepare a solution b with a concentration of 0.5 mol / L. Under continuous stirring and a water bath at 40°C, solution b was slowly added to solution a, and the reaction was continued for 3 h, and then the precipitate and the mother liquor were evaporated to dryness at 110°C to obtain the oxalate precursor precipitate of nickel and manganese powder. The precursor powder was pretreated in a muffle furnace at 550 °C for 5 h to obtain black nickel-manganese oxide powder. Mix stoichiometric lithium carbonate with the obtained nickel-manganese oxide powder (excess lithium carbonate 10%), add ethanol as a grinding aid, grind fully, and then bake at 750-950°C for 15 h, and cool naturally to Room temperature, and finally grind it to get the posit...

Embodiment 2

[0037] The stoichiometric ratio of nickel nitrate hexahydrate and manganese nitrate solution was added to deionized water and dissolved to prepare a solution a with a concentration of 0.5 mol / L. At the same time, an appropriate amount of oxalic acid was weighed to prepare a solution b with the same concentration of 0.5 mol / L. Under continuous stirring and a water bath at 40°C, solution b was slowly added to solution a, reacted for 3 h, and then the precipitate and mother liquor were evaporated to dryness at 110°C to obtain nickel-manganese oxalate precursor powder. The nickel-manganese oxalate precursor powder was pretreated in a muffle furnace at 550 °C for 5 h to obtain a black powder. Fully mix the stoichiometric ratio of lithium carbonate with the obtained black powder (excess lithium carbonate 10%), add isopropanol as a grinding aid, fully grind, then place it at 900 ° C for 15 h, cool naturally to room temperature, and finally Grind it into powder to obtain the positive ...

Embodiment 3

[0039] The stoichiometric ratio of manganese acetate and nickel acetate was added to deionized water and dissolved to prepare a solution a with a concentration of 0.5 mol / L. At the same time, an appropriate amount of oxalic acid was also weighed to prepare a solution b with a concentration of 0.5 mol / L. Under continuous stirring and a water bath at 40 °C, solution b was slowly added to solution a, and the reaction was continued for 3 h after the addition was complete, then the precipitate was filtered, washed several times, and dried to obtain nickel-manganese oxalate precursor powder. The precursor powder was pretreated in a muffle furnace at 550 °C for 5 h to obtain a black powder. Fully mix the stoichiometric ratio of lithium carbonate with the obtained black powder (10% excess lithium carbonate), add acetone as a grinding aid, and grind thoroughly. Then bake at 900 °C for 15 h, cool naturally to room temperature, and finally grind it to obtain the positive electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com