A method for preparing multi-component cerium oxide-based nanosheet material

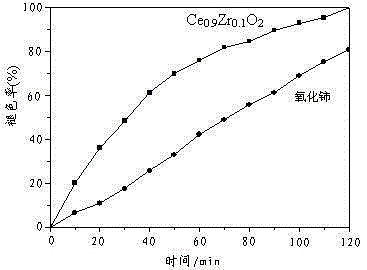

A technology of nano-flakes and cerium oxide, which is applied in the field of preparing nano-flakes materials, and achieves the effects of good experiment repeatability, improved decolorization ability, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

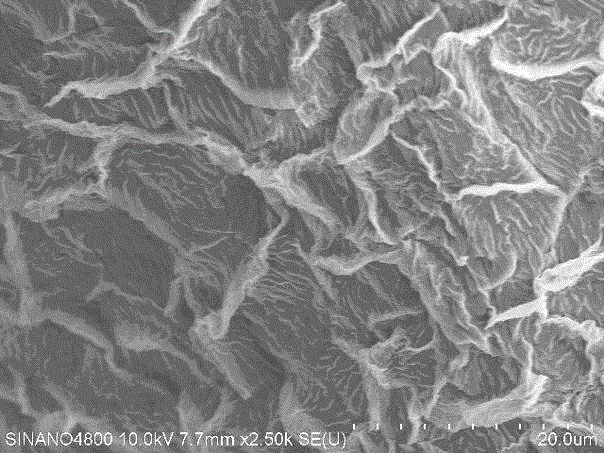

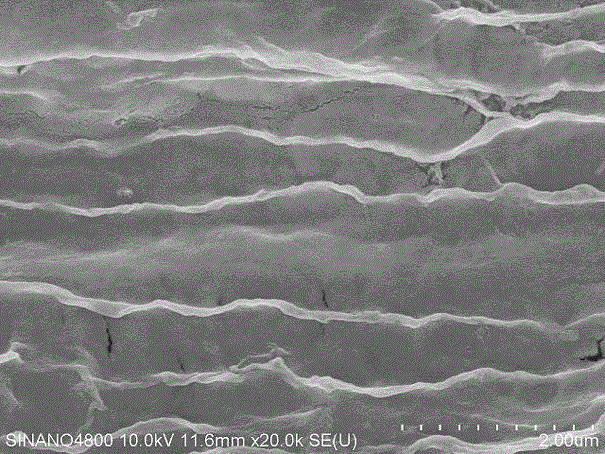

[0029] Collect rose petals, wash the petals with clean water, soak them in 5% dilute hydrochloric acid solution for 2 hours, take them out, wash them with ethanol, and then soak them in 5% dilute hydrochloric acid for 2 hours , then wash it with ethanol, take it out, rinse it repeatedly with clear water and dry it in the shade to form a biological template; prepare an aqueous solution with a ratio of 9:1 with cerium nitrate: zirconium nitrate molar ratio, the total concentration of inorganic salts in the aqueous solution 0.1mol / L, the pretreated biological template was added to the above aqueous solution and immersed for 24 hours; the impregnated product was taken out, the sample was first washed with ethanol aqueous solution, then washed with deionized water, dried, and dried in a muffle In the furnace, the temperature was raised to 550°C at a rate of 2°C / min, kept for 3 hours, and then taken out after natural cooling to obtain Ce 0.9 Zr 0.1 o 2 nanosheet material.

[0030...

Embodiment 2

[0036]Collect peach blossom petals, wash the peach blossom petals with clean water and soak them in a 5% dilute hydrochloric acid solution for 2 hours, take them out, wash them with ethanol, and soak them in 5% dilute hydrochloric acid for 2 hours hour, take it out and then wash it with ethanol, then take it out and rinse it repeatedly with clean water and dry it in the dark to form a biological template; prepare an aqueous solution with a ratio of cerium chloride: copper chloride molar ratio of 9.5:0.5, in the aqueous solution The total concentration of inorganic salts is 0.05mol / L. Add the pretreated biological template into the above aqueous solution and soak for 18 hours; take out the impregnated product, wash the sample with ethanol aqueous solution first, then wash it with deionized water and dry it , and raised the temperature to 700°C at a rate of 2°C / min in the muffle furnace, kept it for 2 hours, and took it out after natural cooling to obtain Ce 0.95 Cu 0.05 o 1.9...

Embodiment 3

[0040] Collect chrysanthemum petals, wash the chrysanthemum petals with water and soak them in a 5% dilute hydrochloric acid solution for 2 hours, take them out, wash them with ethanol, and soak them in 5% dilute hydrochloric acid for 2 hours hour, take it out and wash it with ethanol again, then take it out and rinse it repeatedly with clear water and dry it in the shade to form a biological template; with cerium sulfate:titanium tetrachloride molar ratio is 9.9:0.1 ratio preparation aqueous solution, in the aqueous solution The total concentration of inorganic salts is 0.2mol / L. Add the pretreated biological template into the above aqueous solution and soak for 18 hours; take out the impregnated product, wash the sample with ethanol aqueous solution first, and then wash it with deionized water. Dry, and heat up to 600°C at a rate of 2°C / min in a muffle furnace, keep it warm for 2 hours, and take it out after natural cooling to obtain Ce 0.99 Ti 0.01 o 2 nanosheet material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com