Preparation method of denitration catalyst for effectively inhibiting SO2 oxidation

A denitration catalyst, SO2 technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of blue smoke emission concentration, large deviation of removal efficiency, etc. , to achieve the effect of simple production process, low SO2 conversion rate and good denitration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An effective inhibitor of SO 2 The preparation method of the denitration catalyst of oxidation, the steps are as follows:

[0019] Step 1: Dissolve 0.0343g of ammonium metavanadate, 0.2814g of ammonium paratungstate and 1g of oxalic acid in 20mL of deionized water, and stir at 60°C until ammonium metavanadate, ammonium paratungstate and oxalic acid are dissolved in the solution to become solution 1;

[0020] Step 2: Add 5g of titanium dioxide into 20mL of deionized water and stir to form a suspension 1;

[0021] Step 3: Pour solution 1 into 20mL suspension 1, immerse and stir for 1 hour, then heat to 80°C, continue stirring until it becomes a paste, and dry at 120°C;

[0022] Step 4: Crushing the dried block and calcining in air at 550° C. for 5 hours to obtain the catalyst.

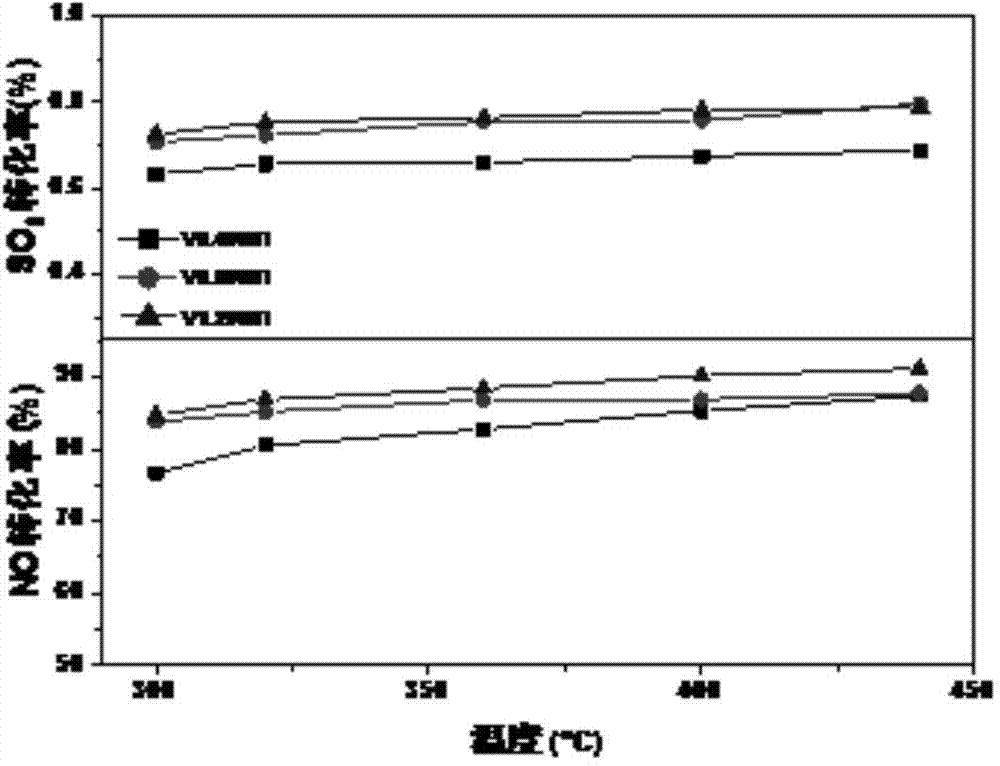

[0023] Catalyst evaluation conditions (the same below): 0.2g catalyst, flue gas concentration 500ppmNH 3 , 500ppm NO, 3%O 2 and 2000ppm SO 2 , the equilibrium gas is N 2 , the total gas volu...

Embodiment 2

[0025] An effective inhibitor of SO 2 The preparation method of the denitration catalyst of oxidation, the steps are as follows:

[0026] Step 1: Weigh 0.0343g of ammonium metavanadate and 0.2814g of ammonium paratungstate respectively, dissolve them in 20mL of 1g of oxalic acid solution, and stir at 60°C until ammonium metavanadate and ammonium paratungstate are dissolved in the oxalic acid solution to become solution 1;

[0027] Step 2: Add 0.0853g of barium nitrate, 0.0837g of magnesium nitrate and 0.0690g of strontium nitrate to 20mL of a suspension containing 5g of titanium dioxide, and stir for 1 hour to form a suspension 1;

[0028] Step 3: Pour solution 1 into suspension 1, immerse and stir for 1 hour, then heat to 80°C, continue to stir until it becomes a paste, and dry at 120°C;

[0029] Step 4: crush the dried block and calcinate in air at 550° C. for 5 hours to obtain the catalyst.

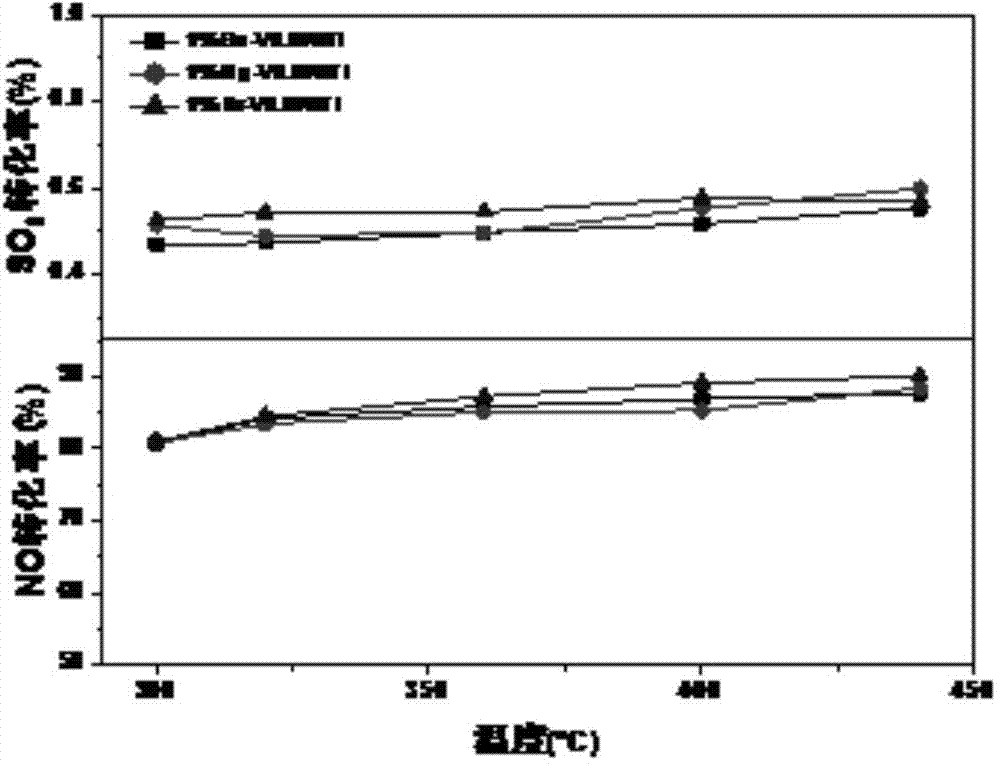

[0030] figure 2 Be the denitrification efficiency and SO of embodiment 2 2 co...

Embodiment 3

[0032] An effective inhibitor of SO 2 The preparation method of the denitration catalyst of oxidation, the steps are as follows:

[0033] Step 1: Dissolve 0.0343g of ammonium metavanadate, 0.2814g of ammonium paratungstate and 1g of oxalic acid in 20mL of deionized water, and stir at 60°C until the ammonium metavanadate and ammonium paratungstate are dissolved in the oxalic acid solution to become solution 1;

[0034] Step 2: Add 0.0853g of barium nitrate to 4.75g of titanium dioxide, 0.83g of silica sol (5wt%); or 4.5g of titanium dioxide, 1.67g of silica sol (10wt%); or 4g of titanium dioxide, 3.35g of silica sol ( 20wt%) in the mixed solution for 1 hour and stirred for 1 hour to become a suspension 1;

[0035] Step 3: Pour solution 1 into suspension 1, immerse and stir for 1 hour, then heat to 80°C, continue to stir until it becomes a paste, and dry at 120°C;

[0036] Step 4: Crushing the dried block and calcining in air at 550° C. for 5 hours to obtain the catalyst.

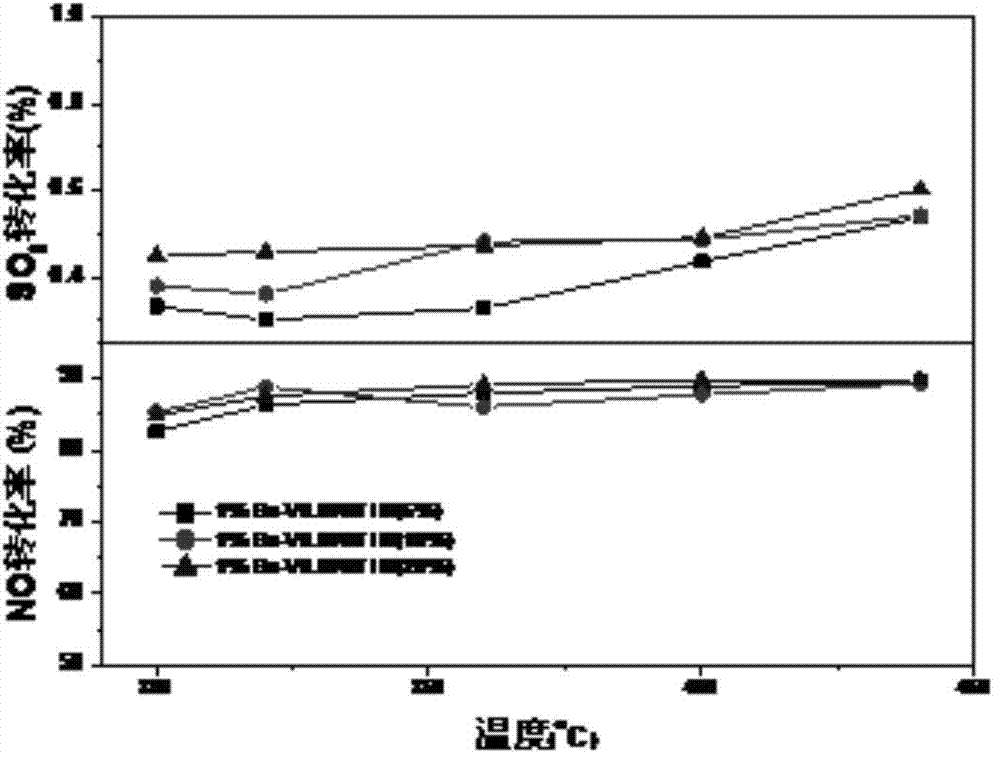

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com