Compound super absorbent resin and preparation method thereof

A technology of superabsorbent resin and sodium bisulfite, which is applied in the field of oil drilling, can solve the problem of high cost and achieve the effect of low cost, low price and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

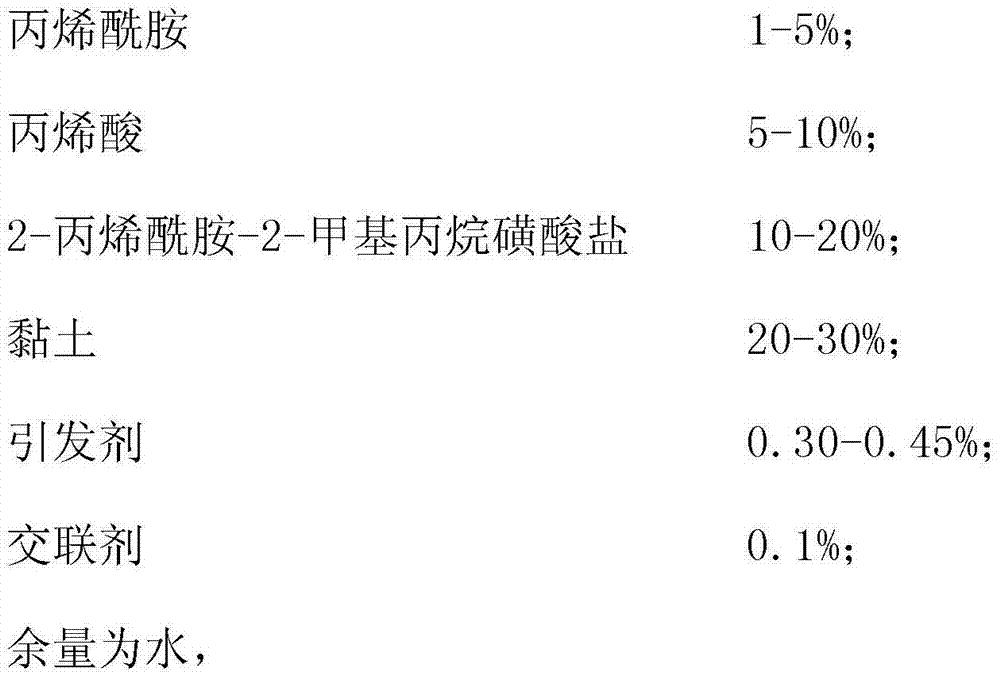

Embodiment 1

[0011] Preparation of composite superabsorbent resin: the weight percentage of each reaction raw material in the preparation process consists of: 5% acrylamide; 10% acrylic acid; 15% 2-acrylamide-2-methylpropanesulfonate; 20% Kaolin; 0.4% ammonium persulfate, sodium bisulfite initiator system, 0.1% crosslinking agent N,N-methylenebisacrylamide, and the balance is water. Specific steps: according to the above weight percentage composition, first add acrylic acid and 2-acrylamide-2-methylpropane sulfonate into distilled water, stir well until the monomers are dissolved, then add acrylamide and kaolin, stir well and then add hydrogen Sodium oxide neutralizes the pH value of the solution to 8-9, and then continues to add an initiator and a crosslinking agent to the solution, react at a constant temperature of 60°C for 4 hours, then dry, pulverize, and granulate to obtain the product.

[0012] Determination of water absorption rate and salt water absorption rate: use sieve filtrati...

Embodiment 2-19

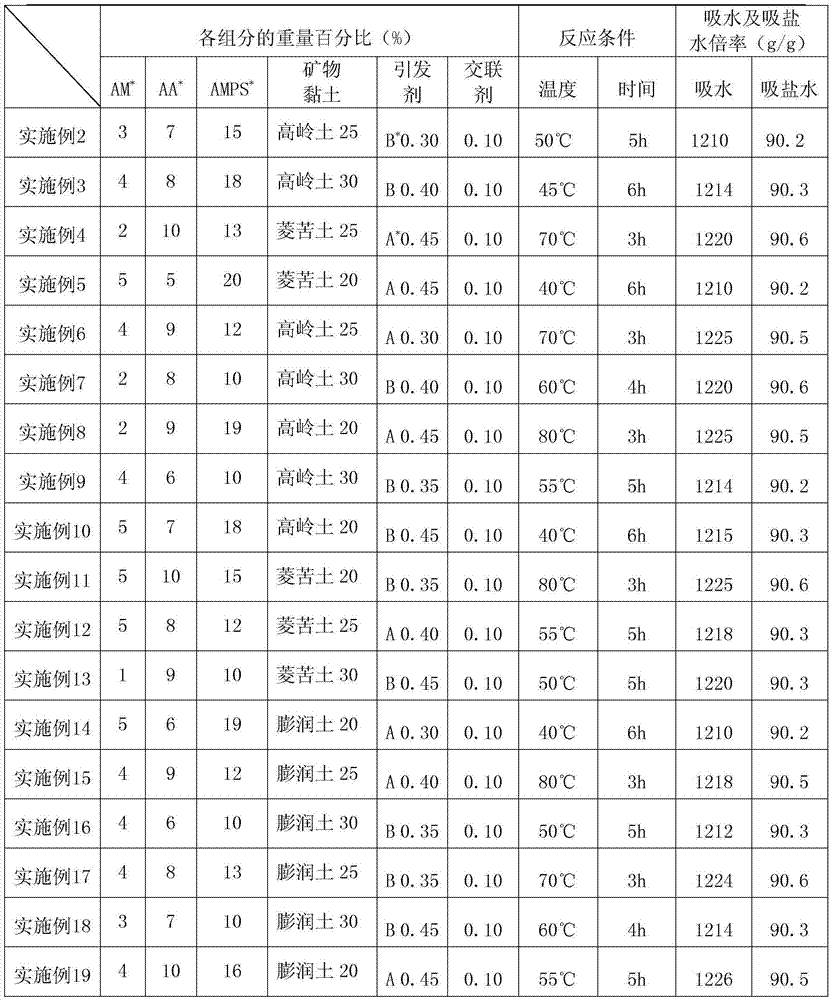

[0015] In order to fully prove the feasibility of the composite superabsorbent resin and its preparation method in the present invention, the composition, proportion and reaction conditions (temperature and time) of each component in the preparation process were changed in Examples 2-19, and the remaining method steps include The determination of the water absorption ratio and the saline absorption ratio is the same as in Example 1, see Table 1 for details.

[0016] The composition, proportioning, reaction conditions and performance test results of each component in the embodiment 2-19 of table 1, in each embodiment in the table, except each component listed, the balance is water

[0017]

[0018] * Note: AM, AA, and AMPS are the abbreviations of acrylamide, acrylic acid, and 2-acrylamide-2-methylpropanesulfonate, respectively, and A and B represent ammonium persulfate, sodium bisulfite system, and potassium persulfate, respectively. Sodium bisulfite system

[0019] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com