Etching liquid composition for copper/molybdenum film or copper/molybdenum alloy film

A technology of composition and molybdenum alloy, which is applied in the field of etching solution composition, can solve problems such as product failure, and achieve the effects of reducing manufacturing costs, reducing failure rate, and slowing down etching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

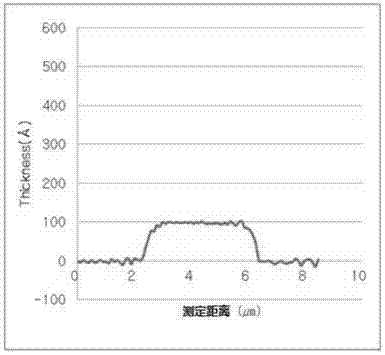

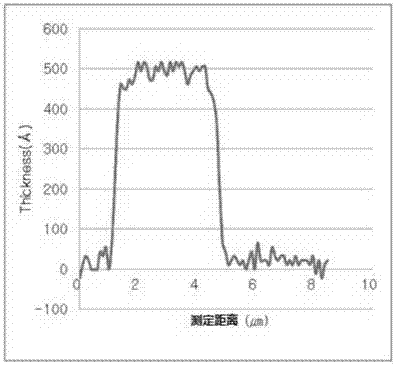

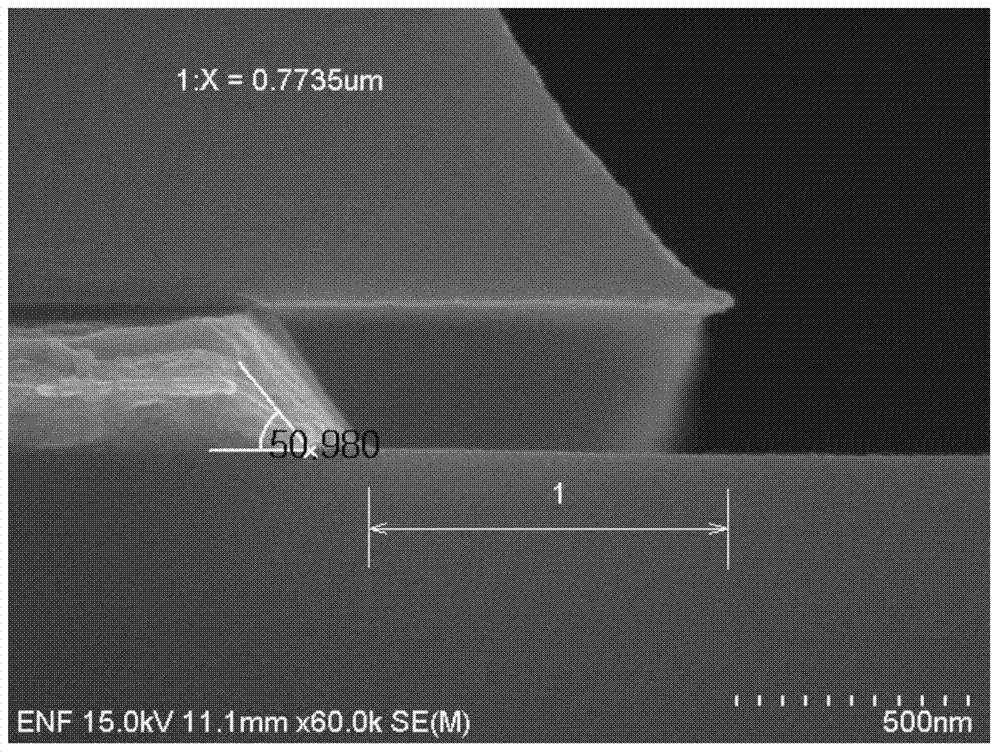

Image

Examples

Embodiment 1 to 14 and comparative example 1

[0035] The contents of the components listed in Table 1 below were mixed to prepare the etching solution compositions of Examples 1 to 14 and Comparative Example 1 of the present invention. The water content is the remaining amount of 100% of the total weight in the composition.

[0036] Table 1

[0037]

[0038] ATZ: 5-aminotetrazole (5-aminotetrazole),

[0039] IDA: iminodiacetic acid (iminodiacetic acid),

[0040] BTZ: benzothiazole (benzothiazole),

[0041] PEG: polyethylene glycol (polyethylene glycol)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com