Application of graphene in energy conversion of moving droplets and methods for energy harvesting and motion sensing

A technology of energy conversion and energy collection, which is used in measuring devices, fluid velocity measurement, indicating/recording actions, etc., to achieve the effect of simple preparation method and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

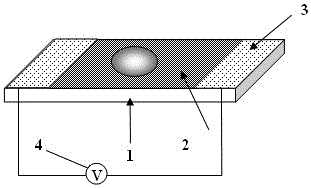

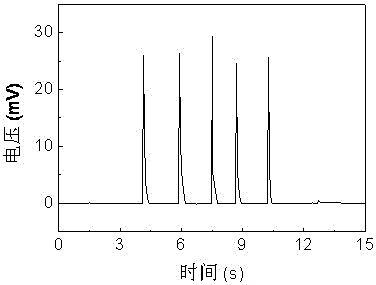

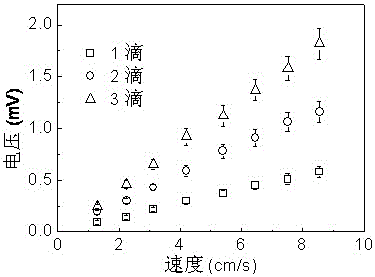

Method used

Image

Examples

preparation example Construction

[0052] The above-mentioned method for preparing the electrode can be direct coating of conductive glue, or standard screen printing process, or vacuum coating process such as ion sputtering, electron beam evaporation, thermal evaporation, or magnetron sputtering.

[0053] The aforementioned hydrophobic materials are paraffin, silica gel, grease, polytetrafluoroethylene and the like.

[0054] The droplets mentioned above can be any liquid containing ions such as salt solution, acid solution, alkali solution, etc. The droplet volume is not limited.

Embodiment 1

[0057] 1. Prepare the polyethylene substrate, ultrasonically clean the substrate with acetone, ethanol, and deionized water for 10 minutes, and then dry.

[0058] 2. Vapor chemical deposition of graphene: Take 25 micron thick copper foil as the base, maintain the growth temperature of 1000 ℃, and pass in methane and hydrogen. The gas flow is 25 sccm of methane and 10 sccm of hydrogen. After 15 minutes of growth, turn off the methane and keep the hydrogen flow at 10 sccm. It is quickly cooled to room temperature under protection, and a graphene material with 1-2 layers is obtained on the copper.

[0059] 3. The graphene is transferred to the polyethylene substrate: the surface of the copper sheet covered with graphene is suspended-coated with PMMA solution. After the solvent evaporates, the copper sheet is soaked in a 0.6M ammonium persulfate solution. After 2 hours, the copper is completely dissolved to obtain The graphene-PMMA layer floating on the solution is transferred to the p...

Embodiment 2

[0064] According to the method of implementation example 1, but the difference from implementation example 1 is

[0065] 1. Prepare the quartz substrate, ultrasonically clean the substrate with acetone, ethanol, and deionized water for 10 minutes, and then dry.

[0066] 2. Vapor chemical deposition of graphene: Take 25 micron thick copper foil as the base, maintain the growth temperature of 1000 ℃, and feed in methane and hydrogen. The gas flow is 40 sccm of methane and 10 sccm of hydrogen. After 15 minutes of growth, turn off the methane and keep the flow of hydrogen at 10 sccm. It is quickly cooled to room temperature under protection, and a graphene material with 1-3 layers is obtained on the copper.

[0067] 3. The graphene is transferred to the polyethylene substrate: the surface of the copper sheet covered with graphene is suspended-coated with PMMA solution. After the solvent evaporates, the copper sheet is soaked in a 0.6M ammonium persulfate solution. After 2 hours, the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com