Memory and preparation method thereof

A memory and memory technology, applied in the field of organic microelectronic materials, can solve the problems of complex manufacturing process, difficult control of semiconductor materials, high cost, etc., and achieve the effect of high response signal, large industrialization potential and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

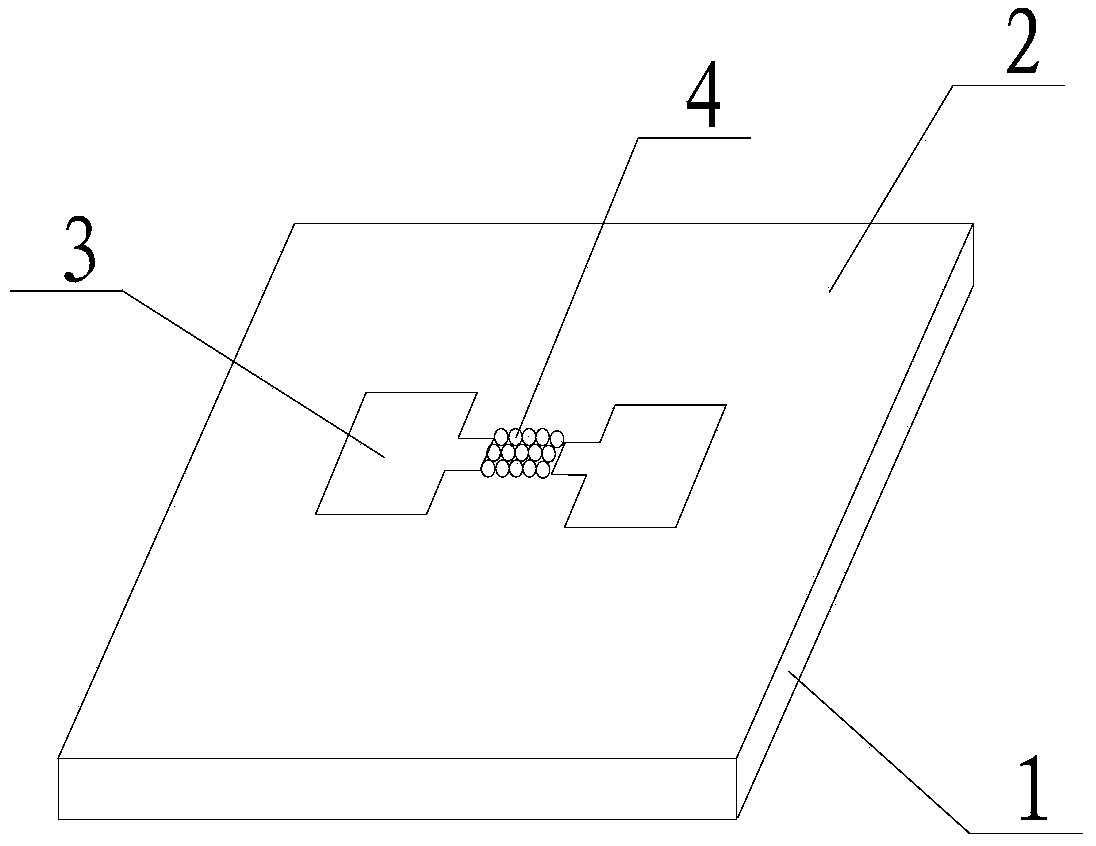

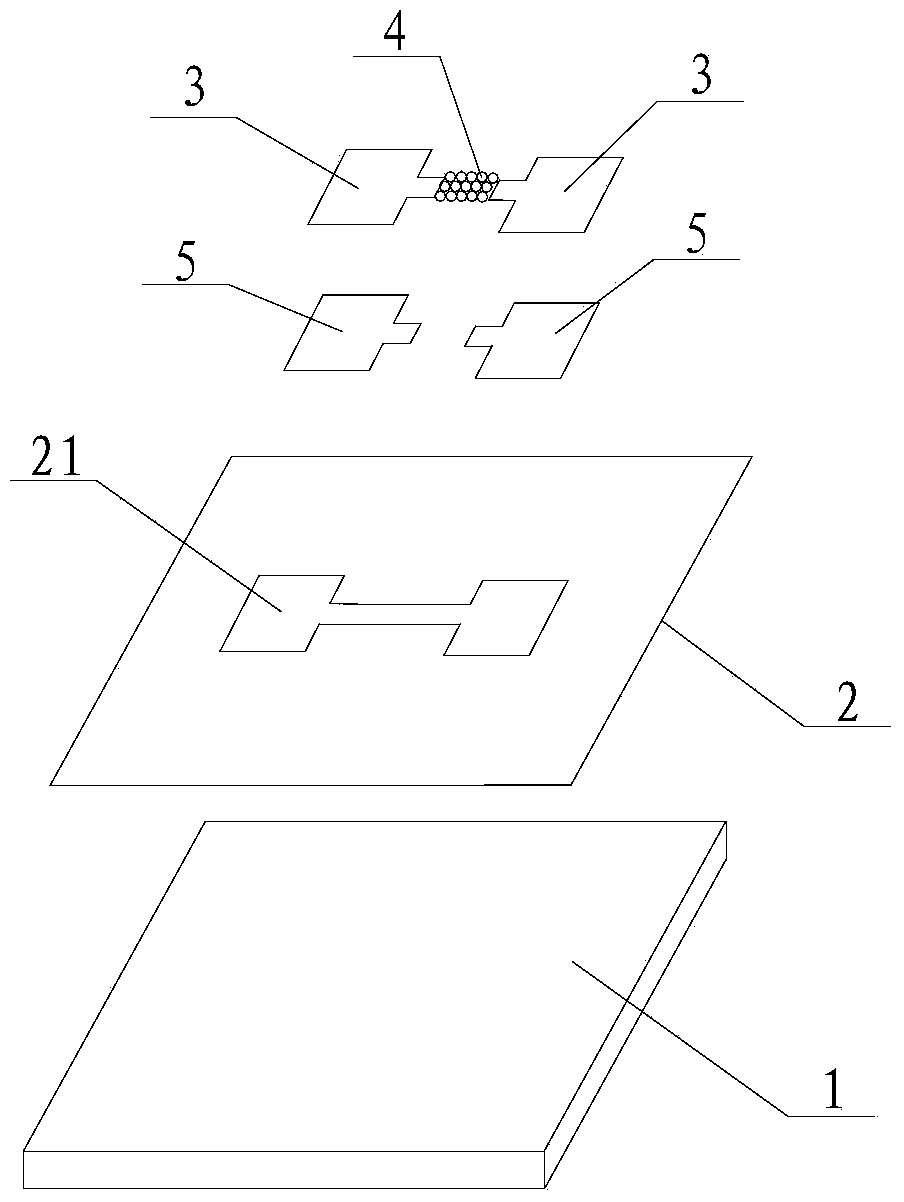

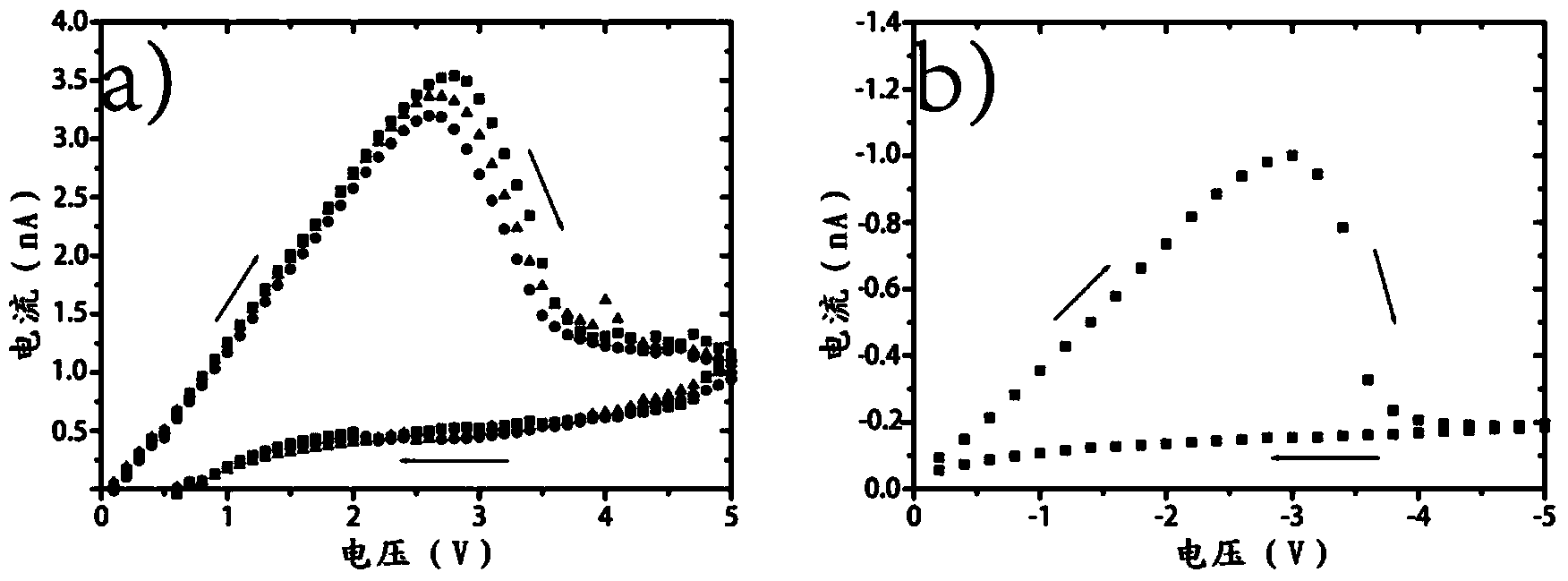

[0030] This embodiment provides a memory storage, such as figure 1 with figure 2 As shown, it mainly includes a semiconductor substrate 1 , an electrode 3 and a thin film layer 4 . Wherein, there are two electrodes 3, which are arranged separately on the upper plane of the semiconductor substrate 1; the thin film layer 4 is also arranged on the upper plane of the semiconductor substrate 1 and connected between the two electrodes 3, and the thin film layer 4 is made of a noble metal coated with a conductive polymer. Nanoparticle composition (i.e. noble metal nanoparticles / conducting polymer composites). Using this composite material to form a thin film layer 4 makes the memory storage device simple in structure, small in size and high in integration, and has great industrialization potential, and the memory storage device has the advantages of low cost, high response signal, and high stability, and has a significant negative differential resistance effect.

[0031] In this ...

Embodiment 2

[0034] This embodiment provides a method for preparing a memory storage device in Embodiment 1, comprising the following steps:

[0035] (a) Spin-coat a layer of photoresist on the semiconductor substrate, heat it at 80-120°C for 1-3 minutes, and carve a cavity on the photoresist;

[0036] (b) Use photolithography or magnetron sputtering technology to first deposit a 3-8nm thick metal chromium layer in the cavity, and then deposit a 15-30nm thick gold layer to form two separated gold electrodes, and then place them in acetone Medium ultrasonic cleaning for about 30 minutes;

[0037] (c) Add 3.6mL of 0.004g / mL chloroauric acid solution to 90.5mL of deionized water, stir and heat to boiling, then add 5mL of 0.0114g / mL sodium citrate solution, and keep boiling for 15min to prepare a 13nm gold nanoparticle solution ;

[0038]Add 25 mL of deionized water, 5 mL of ferric chloride solution with a concentration of 0.125 g / mL, and 50 microliters of pyrrole solution (0.967 g / mL) into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com