Preparation and priming method of medicago sativa seed priming solution

A seed and alfalfa technology, which is applied in the preparation and initiation of alfalfa seed priming solution, can solve the problems of difficult production practice, unfavorable industrialization promotion, and difficult control of sand water content, etc., and achieve simple priming technology and good production application value, eliciting noticeable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

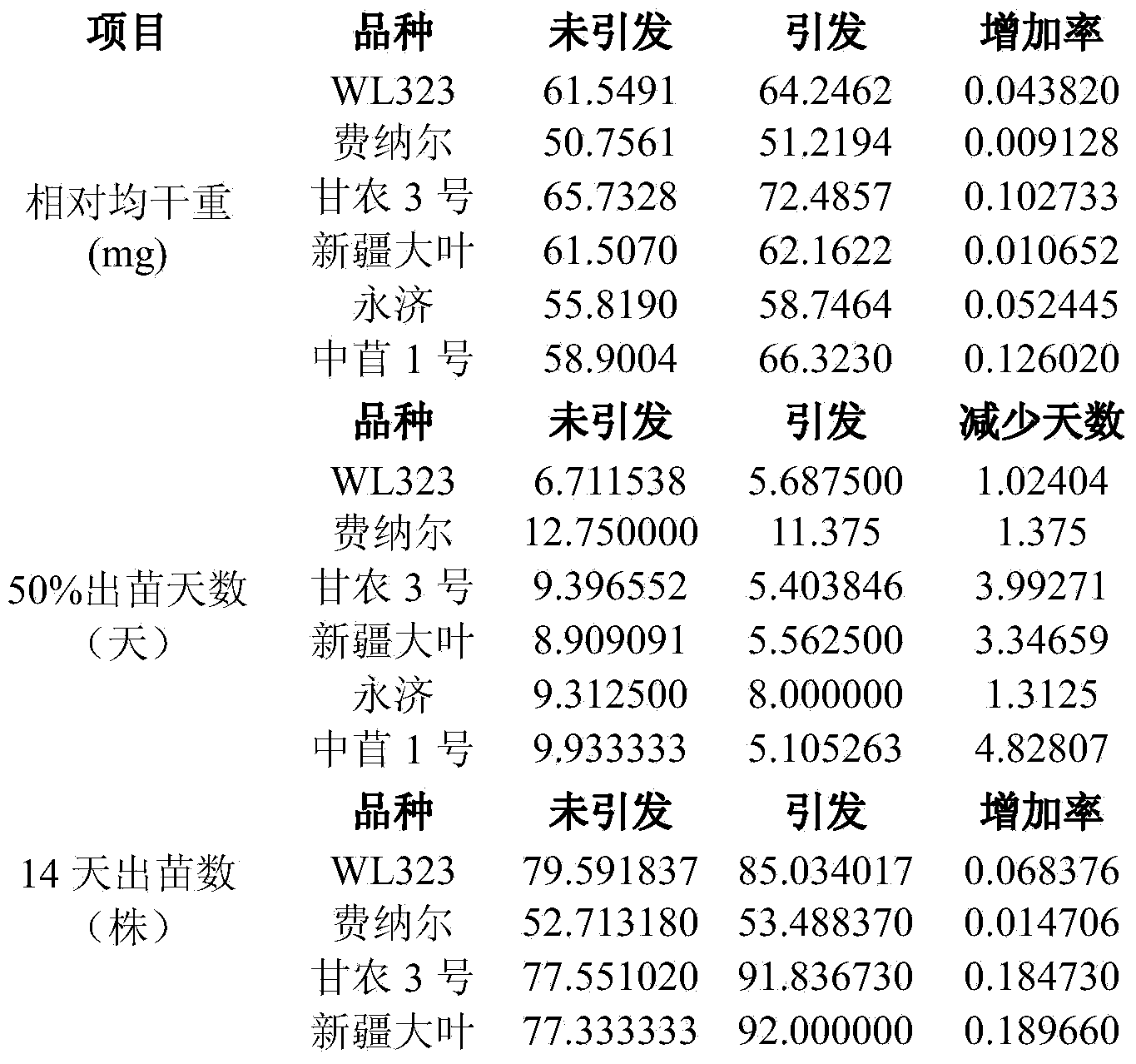

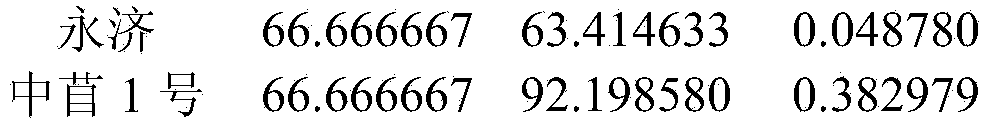

Examples

Embodiment 1

[0075] (1) Raw material preparation for the initiator solution: The raw material components mixed according to the mass fraction ratio are as follows:

[0076] KNO 3 : 160mM

[0077] K H 2 PO 4 : 140mM

[0078] Salicylic acid: 0.15mM

[0079] (2) Initiating solution configuration:

[0080] ① Weigh KNO 3 Dissolve in 1000mL water, stir until dissolved, and make a 160mM solution, due to KNO 3 Dust is irritating to the respiratory tract, if a large amount of KNO is inhaled 3 The powder can cause pulmonary edema; it is also highly irritating to the skin and eyes. Repeated skin contact can cause skin dryness, chapping and rashes. Therefore, corresponding protective equipment should be worn during use.

[0081] ② Weigh KH 2 PO 4 Dissolve in 1000mL of the above solution, stir until dissolved, and make KH 2 PO 4 up to 140mM;

[0082] ③Heat the above solution on a heater, weigh salicylic acid at the same time, pour it into the solution, and stir until it dissolves so that t...

Embodiment 2

[0091] (1) Raw material preparation for the initiator solution: The raw material components mixed according to the mass fraction ratio are as follows:

[0092] KNO 3 : 140mM

[0093] K H 2 PO 4 : 120mM

[0094] Salicylic acid: 0.1mM

[0095] (2) Initiating solution configuration:

[0096] ①Weigh 0.0138g of salicylic acid, measure 5mL of absolute ethanol, pour salicylic acid into absolute ethanol, stir until dissolved,

[0097] ② Weigh KNO 3 14.15g, pour it into 1000mL water, then add the absolute ethanol with salicylic acid dissolved in it, stir until dissolved, because KNO3 dust is irritating to the respiratory tract, if you inhale a large amount of KNO3 3 The powder can cause pulmonary edema; it is also highly irritating to the skin and eyes, and repeated skin contact can cause dry skin, chapped skin and rash. Therefore, corresponding protective equipment should be worn during use.

[0098] ③ Weigh KH 2 PO 4 16.33g, dissolved in 1000mL of the above solution, stirr...

Embodiment 3

[0107] (1) Raw material preparation for the initiator solution: The raw material components mixed according to the mass fraction ratio are as follows:

[0108] KNO 3 : 180mM

[0109] K H 2 PO 4 : 160mM

[0110] Salicylic acid: 0.2mM

[0111] (2) Initiating solution configuration:

[0112] ① Weigh KH 2 PO 4 21.77g, dissolved in 1000mL water, stirred until dissolved,

[0113] ② Weigh KNO 3 18.20g, pour into the above 1000mL water, stir until dissolved, because KNO3 dust is irritating to the respiratory tract, if a large amount of KNO3 is inhaled 3 The powder can cause pulmonary edema; it is also highly irritating to the skin and eyes, and repeated skin contact can cause skin dryness, chapping and rash. Therefore, corresponding protective equipment should be worn during use.

[0114] ③Heat the above solution on a heater, weigh 0.0276g of salicylic acid at the same time, pour it into the solution, stir until it dissolves, and finally obtain the prepared trigger solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com