Metal-organic framework MOF material with high methane adsorption and storage density

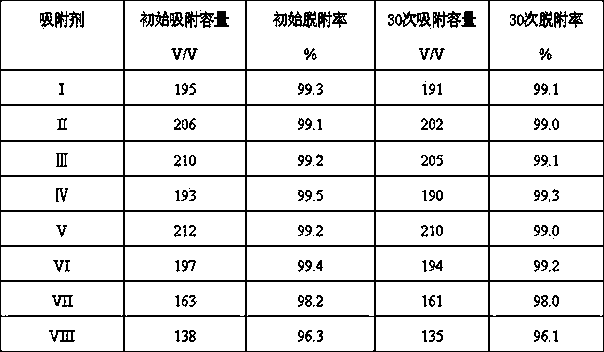

A storage density, organic framework technology, applied in organic chemistry, bismuth organic compounds, iron organic compounds, etc., can solve the problems of complex preparation and molding process, small methane adsorption capacity, unstable quality, etc., and achieve excellent molecular diffusion and adsorption. --Desorption performance, large adsorption capacity, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.92 g of 5-sulfonic acid group, 0.92 g of 2,7-naphthalene dicarboxylic acid and 0.30 g of ferric chloride hydrate into a 100 mL Teflon stainless steel reaction kettle, then add 15 mL of cyclohexanol, 10 mL of ethanol and 20 mL of deionized water, and stir After uniform sealing, react at 110-120°C for 20-24 hours. The product is cooled to room temperature to obtain a colorless block crystal, which is filtered and dried, and then evaporated in a nitrogen stream at 110°C to remove water and solvents to make MOF. Adsorbent I.

Embodiment 2

[0023] Add 0.78 g of 1-nitro, 2, 6-naphthalene dicarboxylic acid and 0.35 g of aluminum chloride hydrate into a 100 mL Teflon stainless steel reaction kettle, then add 10 mL of cyclohexanol, 15 mL of ethanol and 20 mL of deionized water, and stir well After sealing, react at 110-120°C for 20-24 hours. The product is cooled to room temperature to obtain a colorless block crystal, which is filtered and dried, and then volatilized in a nitrogen stream at 110°C to remove water and solvent to make MOF adsorption. Agent II.

Embodiment 3

[0025] Add 0.95 g of 3-amino, 2,6-naphthalene dicarboxylic acid and 0.62 g of hydrated lanthanum nitrate into a 100mL Teflon stainless steel reaction kettle, then add 5 mL of methylcyclohexanol, 12 mL of ethanol and 20 mL of deionized water, stir evenly and seal Afterwards, react at 110-120°C for 20-24 hours. The product is cooled to room temperature to obtain a colorless block crystal, which is filtered and dried, and then evaporated to remove water and solvent in a nitrogen stream at 110°C to make a MOF adsorbent. III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com