A kind of large-scale production of metal oxide nano-powder preparation method

An oxide, large-scale technology, applied in the direction of oxide/hydroxide preparation, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of high requirements for experimental equipment and experimental conditions, and is not suitable for large-scale Problems such as industrial promotion and easy agglomeration of nano-powder to achieve the effect of uniform product dispersion, fast reaction speed, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of zinc oxide nanopowder:

[0034] 1) Weigh Zn(NO 3 )·6H 2 Pour O14.6206g into a beaker, add an appropriate amount of deionized water to dissolve, then add citric acid (20.6610g) with twice the amount of metal ions (that is, twice the total number of zinc ions) to the solution, and mix well until completely dissolved In a solvent, a sol is formed;

[0035] 2) Add ammonia water dropwise to the above sol to adjust the pH of the sol to 7;

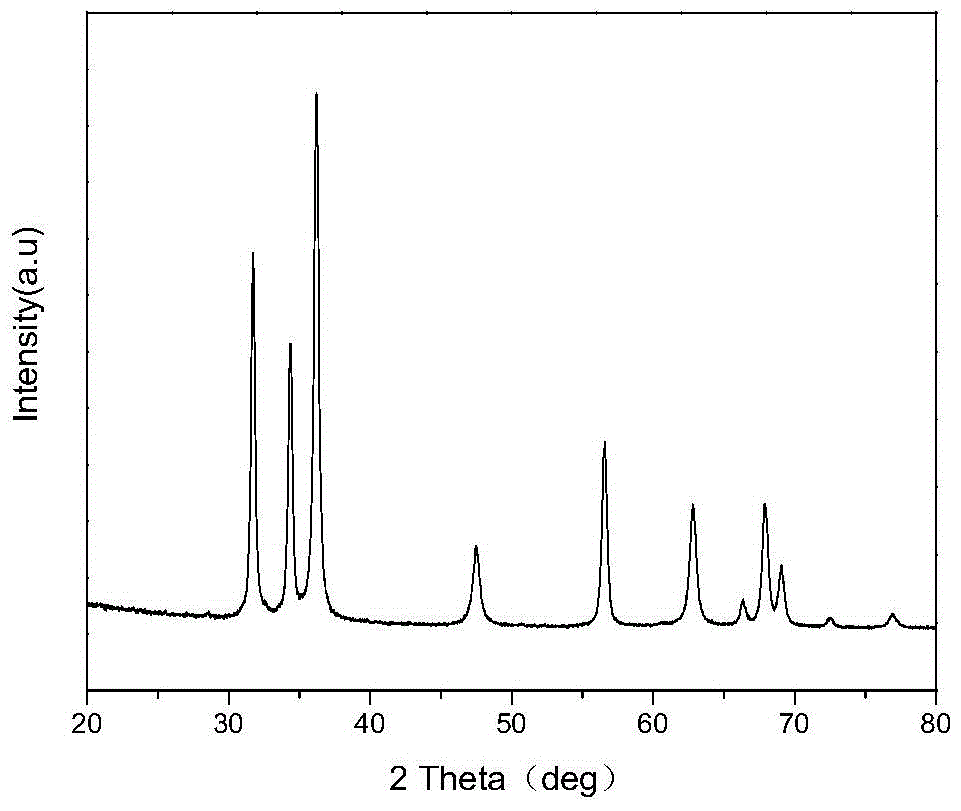

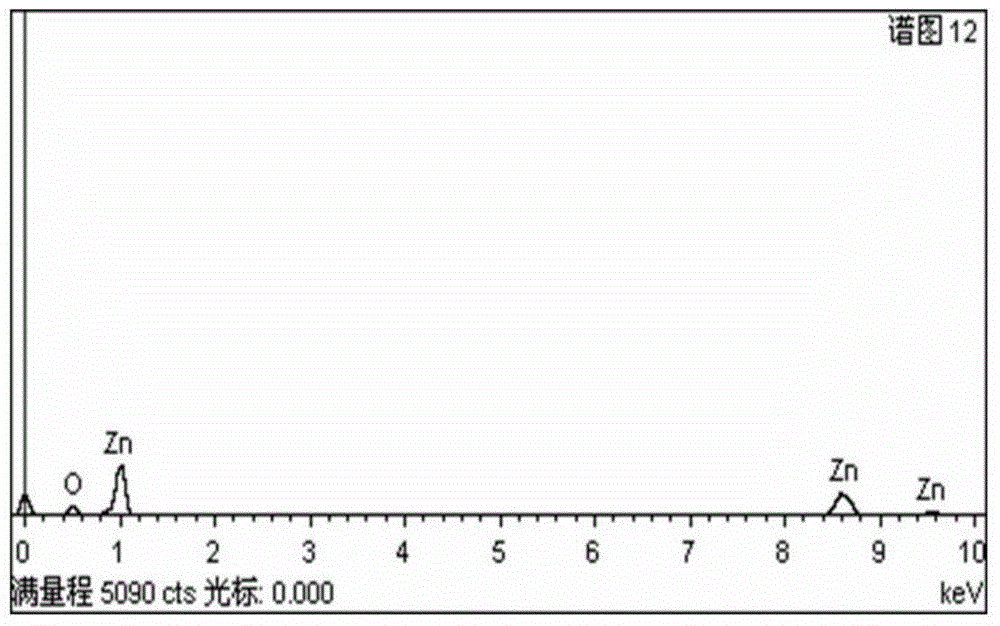

[0036] 3) The sol with a pH of 7 is passed through a spray device to form mist droplets, which are sprayed on a heat source at 600°C for combustion to obtain zinc oxide nanopowder (such as Figure 1-3 shown). The phase formation temperature of zinc oxide is about 510°C (such as Figure 4 shown).

Embodiment 2

[0038] Preparation of Composite Metal Oxide Zn 0.982 Y 0.018 o 1-δ Nano powder:

[0039] 1) Weigh Zn(NO 3 )·6H 2 O14.6206g is poured into a beaker, add an appropriate amount of deionized water to dissolve, according to the stoichiometric ratio of Y and Zn in the composite metal oxide, measure the yttrium nitrate solution of 24.6ml volume (the preparation of yttrium nitrate solution: weigh 6.8942g six Water yttrium nitrate, add appropriate amount of deionized water to dissolve, and transfer the solution to a 500ml volumetric flask to constant volume) Pour into the zinc nitrate solution and mix evenly, then add 2 times the amount of metal ions (that is, zinc ions and yttrium The citric acid (21.0334g) of 2 times of the total molar number of ions) is fully mixed until completely dissolved in the solvent to form a sol;

[0040] 2) Add ammonia water dropwise to the above sol to adjust the pH of the sol to 7;

[0041] 3) The sol with a pH of 7 is passed through a spray device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com