Method for producing graphene based on sodium dodecylbenzene sulfonate

A technology of sodium dodecylbenzene sulfonate and graphene, which is applied in the direction of graphene and nano-carbon, can solve the problems of complex chemical vapor deposition process, low yield of micro-mechanical stripping method, and low quality of graphene. Achieve the effects of high practicability, popularization and application value, low price, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

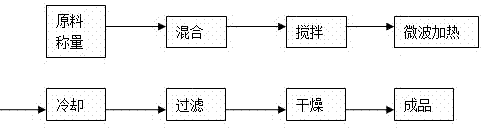

[0029] Example 1: Press figure 1 Shown, the production raw material and proportioning are:

[0030] Expanded graphite: 5%

[0031] Nitromethylpyrrolidone: 45%

[0032] Sodium dodecylbenzenesulfonate: 5%

[0033] Ethanol: 45%

[0034] The preparation process of graphene is:

[0035] (1) Weigh various raw materials as required;

[0036] (2) Put various raw materials into the container and mix and stir to make the raw material composition uniform;

[0037] (3) Put the uniformly mixed raw materials together with the container into a microwave oven for microwave heating. The characteristics are: the heating power is 500W, and the heating time is 30 minutes;

[0038] (4) Turn off the power of the microwave oven and let the product cool down slowly in the microwave oven;

[0039] (5) After the product is cooled to room temperature, it is taken out from the microwave oven, then filtered and dried, and finally the graphene product is obtained.

[0040]

Embodiment 2

[0041] Example 2: Press figure 1 Shown, the production raw material and proportioning are:

[0042] Expanded graphite: 10%

[0043] Nitromethylpyrrolidone: 40%

[0044] Sodium dodecylbenzenesulfonate: 10%

[0045] Ethanol: 40%

[0046] The preparation process of graphene is:

[0047] (1) Weigh various raw materials as required;

[0048] (2) Put various raw materials into the container and mix and stir to make the raw material composition uniform;

[0049] (3) Put the uniformly mixed raw materials together with the container into the microwave oven for microwave heating. The characteristics are: the heating power is 600W, and the heating time is 25 minutes;

[0050] (4) Turn off the power of the microwave oven and let the product cool down slowly in the microwave oven;

[0051] (5) After the product is cooled to room temperature, it is taken out from the microwave oven, then filtered and dried, and finally the graphene product is obtained.

[0052]

Embodiment 3

[0053] Embodiment 3: press figure 1 Shown, the production raw material and proportioning are:

[0054] Expanded graphite: 15%

[0055] Nitromethylpyrrolidone: 35%

[0056] Sodium dodecylbenzenesulfonate: 15%

[0057] Ethanol: 35%

[0058] The preparation process of graphene is:

[0059] (1) Weigh various raw materials as required;

[0060] (2) Put various raw materials into the container and mix and stir to make the raw material composition uniform;

[0061] (3) Put the uniformly mixed raw materials together with the container into the microwave oven for microwave heating. The characteristics are: the heating power is 700W, and the heating time is 20 minutes;

[0062] (4) Turn off the power of the microwave oven and let the product cool down slowly in the microwave oven;

[0063] (5) After the product is cooled to room temperature, it is taken out from the microwave oven, then filtered and dried, and finally the graphene product is obtained.

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com