Admixture special for color concrete and application method and using method of admixture

A technology of colored concrete and admixtures, applied in the field of building materials, can solve the problems of large slump loss, high cost, difficult dispersion of pigment agglomeration, etc., to improve alkali resistance, improve bonding strength, and good water reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

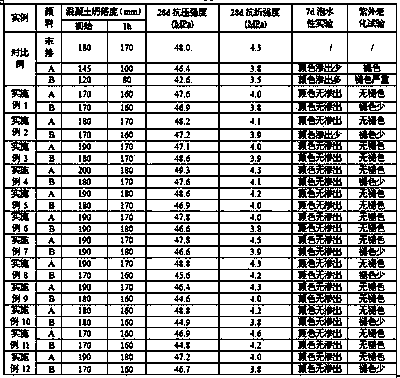

Examples

Embodiment 1

[0033] In terms of mass fraction, the mixing ratio of special admixtures for colored concrete is:

[0034] Water-reducing dispersible components: 8 parts of modified sodium lignosulfonate, 30 parts of polymethylene naphthalene sodium sulfonate, 5 parts of sodium dodecylsulfonate, and 57 parts of water. The dosage is 1.5% of the weight of the concrete cementitious material.

[0035] Modified durable components: 16 parts of styrene-maleimide, 15 parts of γ-glycidyl ether propyl trimethoxysilane, 20 parts of sodium stearate, 46 parts of styrene / acrylate copolymer, 2, 3 parts of sodium benzophenone 2'-dihydroxy-4,4'dimethoxy-5,5'disulfonate. The dosage is 2.0% of the weight of the concrete cementitious material.

[0036] Colored concrete is composed of mineral powder, cement, other mineral admixtures, water, pigments, special admixtures for concrete, coarse aggregate, and fine aggregate. The cementitious materials are: mineral powder, cement, and other mineral admixtures.

[0...

Embodiment 2

[0044] In terms of mass fraction, the mixing ratio of special admixtures for colored concrete is:

[0045] Water-reducing dispersible components: 20 parts of modified sodium lignosulfonate, 28 parts of polymethylene naphthalene sodium sulfonate, 2 parts of sodium dodecylsulfonate, and 50 parts of water. The dosage is 1.0% of the weight of the concrete cementitious material.

[0046] Modified durable components: 8 parts of styrene-maleimide, 28 parts of γ-glycidyl ether propyl trimethoxysilane, 8 parts of sodium stearate, 49 parts of styrene / acrylate copolymer, 2, 7 parts of sodium 2'-dihydroxy-4,4'dimethoxy-5,5'disulfonate benzophenone. The dosage is 1.5% of the weight of the concrete cementitious material.

[0047] All the other are with embodiment 1.

[0048]

Embodiment 3

[0050] In terms of mass fraction, the mixing ratio of special admixtures for colored concrete is:

[0051] Water-reducing dispersible components: 20 parts of modified sodium lignosulfonate, 15 parts of polymethylene naphthalene sodium sulfonate, 1 part of sodium dodecylsulfonate, and 64 parts of water. The dosage is 2.0% of the weight of the concrete cementitious material.

[0052]Modified durable components: 15 parts of styrene-maleimide, 18 parts of γ-glycidyl ether propyl trimethoxysilane, 20 parts of sodium stearate, 40 parts of styrene / acrylate copolymer, 2, 7 parts of sodium 2'-dihydroxy-4,4'dimethoxy-5,5'disulfonate benzophenone. The dosage is 3.0% of the weight of the concrete cementitious material.

[0053] All the other are with embodiment 1.

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com