Chitosan double-network quick response-type injectable hydrogel and preparation method thereof

A technology of chitosan and water injection, applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of poor mechanical properties of temperature-sensitive gels, unfavorable rapid prototyping, and long response time, and achieve good thermal stability and short transition time control, short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: gel forming method of gel and detection of gel forming time by inversion method

[0027]Weigh 3.0 g of chitosan powder (deacetylation degree 96%, molecular weight 100 kDa), dissolve it in 50 mL of 0.1 mol / L hydrochloric acid solution, and obtain a chitosan solution with a mass fraction of 6%. Take out 9mL of this solution, and add 1mL of sodium glycerophosphate solution with a mass fraction of 50% (in which β-sodium glycerophosphate accounts for 90% of the solid powder of sodium glycerophosphate) dropwise in an ice-water bath at 0°C. After the addition is complete, at this time The pH value of the solution is about 7.2, and the solution is stored at 4°C, and this solution is used as solution A. Weigh 0.11 g of glutaraldehyde (mass ratio to chitosan in liquid A is 0.02:1) and dissolve it in 1 mL of water, and this solution is used as liquid B.

[0028] Put liquid A and liquid B into tube A and tube B respectively, where the maximum volume of tube A is 10 m...

Embodiment 2

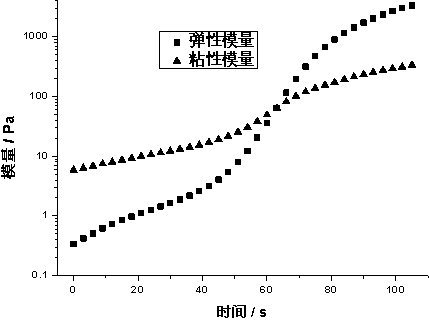

[0029] Example 2: Detection of gelation time by cone-plate rotational rheometer

[0030] Weigh 3.0 g of chitosan powder (deacetylation degree 96%, molecular weight 100 kDa), dissolve it in 50 mL of 0.1 mol / L hydrochloric acid solution, and obtain a chitosan solution with a mass fraction of 6%. Take out 9mL of this solution, and add 1mL of sodium glycerophosphate solution with a mass fraction of 50% (in which β-sodium glycerophosphate accounts for 90% of the solid powder of sodium glycerophosphate) dropwise in an ice-water bath at 0°C. After the addition is complete, at this time The pH value of the solution is about 7.2, and the solution is stored at 4°C, and this solution is used as solution A. Weigh 0.11 g of glutaraldehyde (mass ratio to chitosan in liquid A is 0.02:1) and dissolve it in 1 mL of water, and this solution is used as liquid B.

[0031] Put liquid A and liquid B into tube A and tube B respectively, where the maximum volume of tube A is 10 mL, and the maximum v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com