Silver nanowire and zinc oxide nanowire monolayer transparent electrode and preparing method thereof

A technology of zinc oxide nanowires and silver nanowires, which is applied in the direction of oxide conductors, cable/conductor manufacturing, circuits, etc., can solve the problem of self-assembly of zinc oxide nanowires and silver nanowires, and achieve surface morphology The effect of leveling, regulating the degree of compounding, and small film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

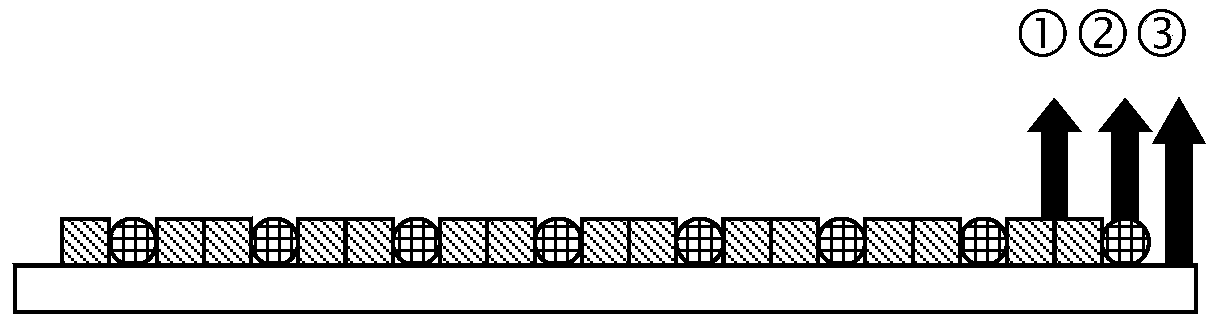

[0035] ①Remove the outer protective film of transparent polymer flexible substrates such as PET.

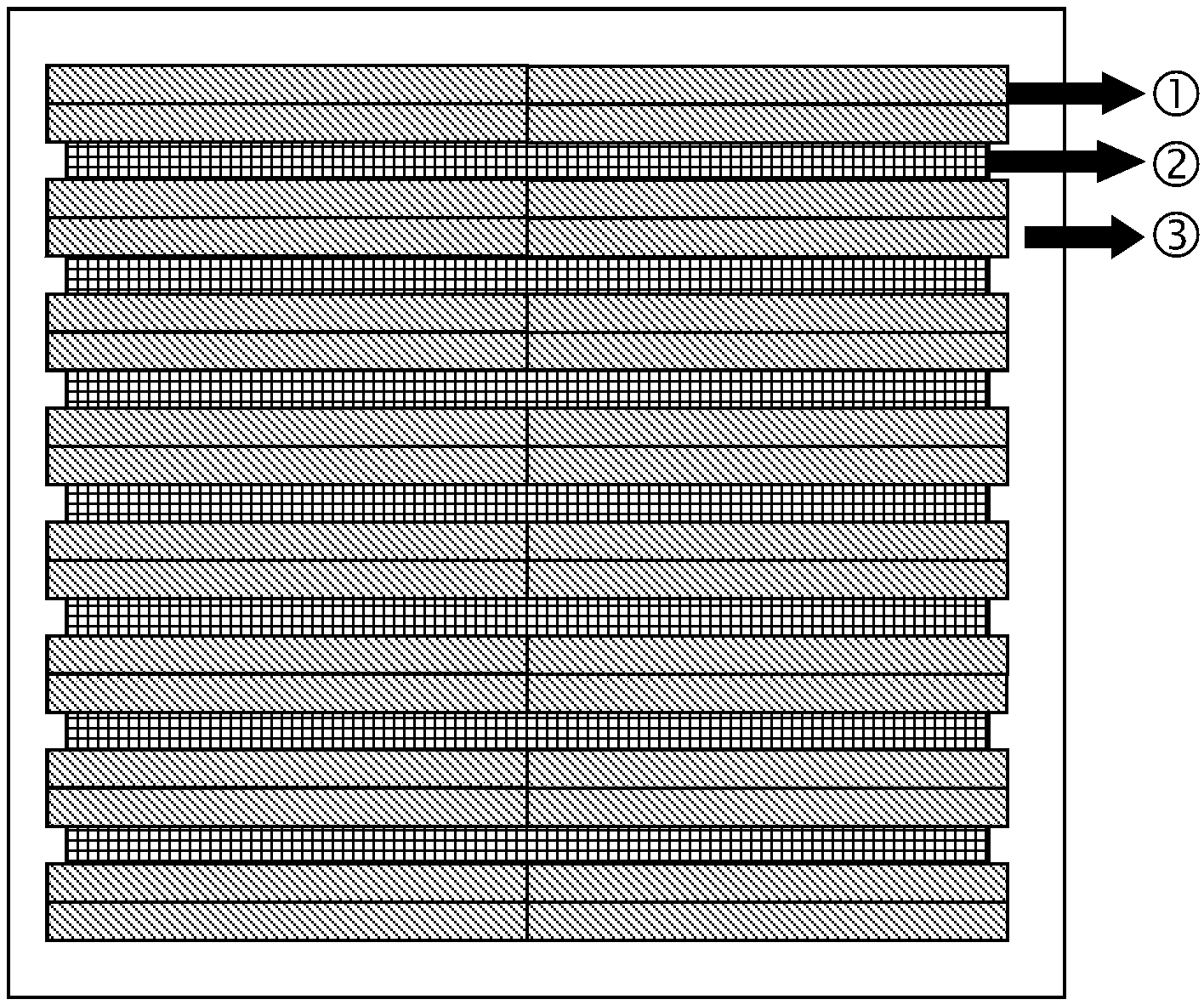

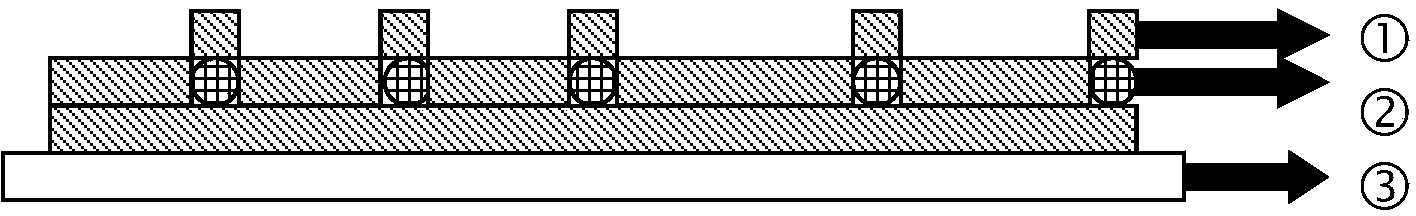

[0036] ② Disperse silver nanowires and zinc oxide nanowires evenly in ethanol, isopropanol, water, nitrogen nitrogen dimethylformamide (DMF), and prepare silver nanowires and zinc oxide nanowires on a polymer substrate by the LB method. Wire composite structure film. The thickness of the composite structure is between 5nm and 300nm.

[0037]③ Place the composite structure film in an environment of room temperature to 120° for 10 to 50 minutes to remove the remaining solvent.

[0038] ④Place the composite structure film under a pressure of 30Mpa to make the composite between the silver nanowires and zinc oxide nanowires more compact, and make the composite film of silver nanowires, silver nanowires, zinc oxide nanowires.

Embodiment 2

[0040] ①Remove the outer protective film of transparent polymer flexible substrates such as PET.

[0041] ② Disperse silver nanowires and zinc oxide nanowires evenly in ethanol, isopropanol, water, nitrogen nitrogen dimethylformamide (DMF), and prepare silver nanowires and zinc oxide nanowires on a polymer substrate by pulling method Composite structure film. The thickness of the composite structure is between 5nm and 300nm.

[0042] ③ Place the composite structure film in an environment of room temperature to 120° for 10 to 50 minutes to remove the remaining solvent.

[0043] ④Place the composite structure film under a pressure of 30Mpa to make the composite between the silver nanowires and zinc oxide nanowires more compact, and make the composite film of silver nanowires, silver nanowires, zinc oxide nanowires.

Embodiment 3

[0045] ①Remove the outer protective film of transparent polymer flexible substrates such as PET.

[0046] ② The silver nanowires were uniformly dispersed in the aqueous solution, and the zinc oxide nanowires were dispersed in the chloroform solution, and the silver nanowires and the zinc oxide nanowires composite structure film were prepared on the polymer substrate by liquid-liquid interface assembly. The thickness of the composite structure is between 5nm and 300nm.

[0047] ③ Place the composite structure film in an environment of room temperature to 120° for 10 to 50 minutes to remove the remaining solvent.

[0048] ④Place the composite structure film under a pressure of 30Mpa to make the composite between the silver nanowires and zinc oxide nanowires more compact, and make the composite film of silver nanowires, silver nanowires, zinc oxide nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com