Preparation method of cobalt-doped amorphous carbon film/silicon photovoltaic device

An amorphous carbon film and device technology, applied in the field of cobalt-doped amorphous carbon film/silicon photovoltaic device and its preparation, can solve the problems of poor corrosion resistance and reuse performance, high production cost, long production cycle, etc. Low cost, high working stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

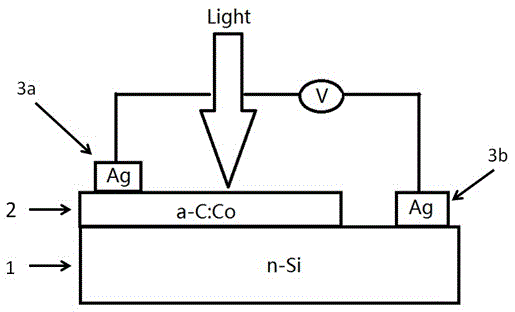

[0019] Prototypes are made according to the above-mentioned technical scheme. The N-type silicon (n-Si) substrate is a phosphorus-doped n-Si substrate, and its resistivity is 8-13Ω·cm. On one area of the substrate (the upper surface of one end of the substrate), a cobalt-doped amorphous carbon a-C:Co film was prepared by pulsed laser deposition using 99.99% pure graphite and 99.9% metallic Co as targets. Source, the metal Co sheet is pasted on the graphite target. During operation, uniform doping is achieved by the rotation of the target and the sample substrate. The Co doping amount is about 10%, the laser energy is 320 mJ / pulse, and the vacuum degree of the cavity is 1×10 -4 mBar, the substrate temperature is 400°C, the distance between the target and the substrate is 5cm, the temperature is naturally cooled to room temperature after coating, and the film thickness is about 25nm. Then adopt the vacuum thermal evaporation method, by the control of the mask plate, on the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com