A method for preparing surface-modified ceo2 nanomaterials, as well as products and applications

A nanomaterial and surface modification technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of low carrier mobility, poor chemical stability, high cost, and achieve high carrier mobility. efficiency, simple preparation method, and simple mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1, comprises the steps:

[0076] (1) Weigh cerium nitrate hexahydrate and dissolve it in distilled water to configure a concentration of 17mmol / L, and add tert-butylamine dropwise under the condition of an ice-water bath until the pH is 8;

[0077] (2) Take 150 milliliters of the solution described in step (1) and add it to a 500 milliliter reaction kettle, add oleic acid, configure the precursor solution protected by oleic acid with a molar ratio of oleic acid and cerium ion of 10:1, and protect it by oleic acid The volume ratio of precursor solution and toluene is 1:1, add toluene (you can replace toluene with benzene, n-hexane, carbon tetrachloride or dichloromethane), let stand without stirring;

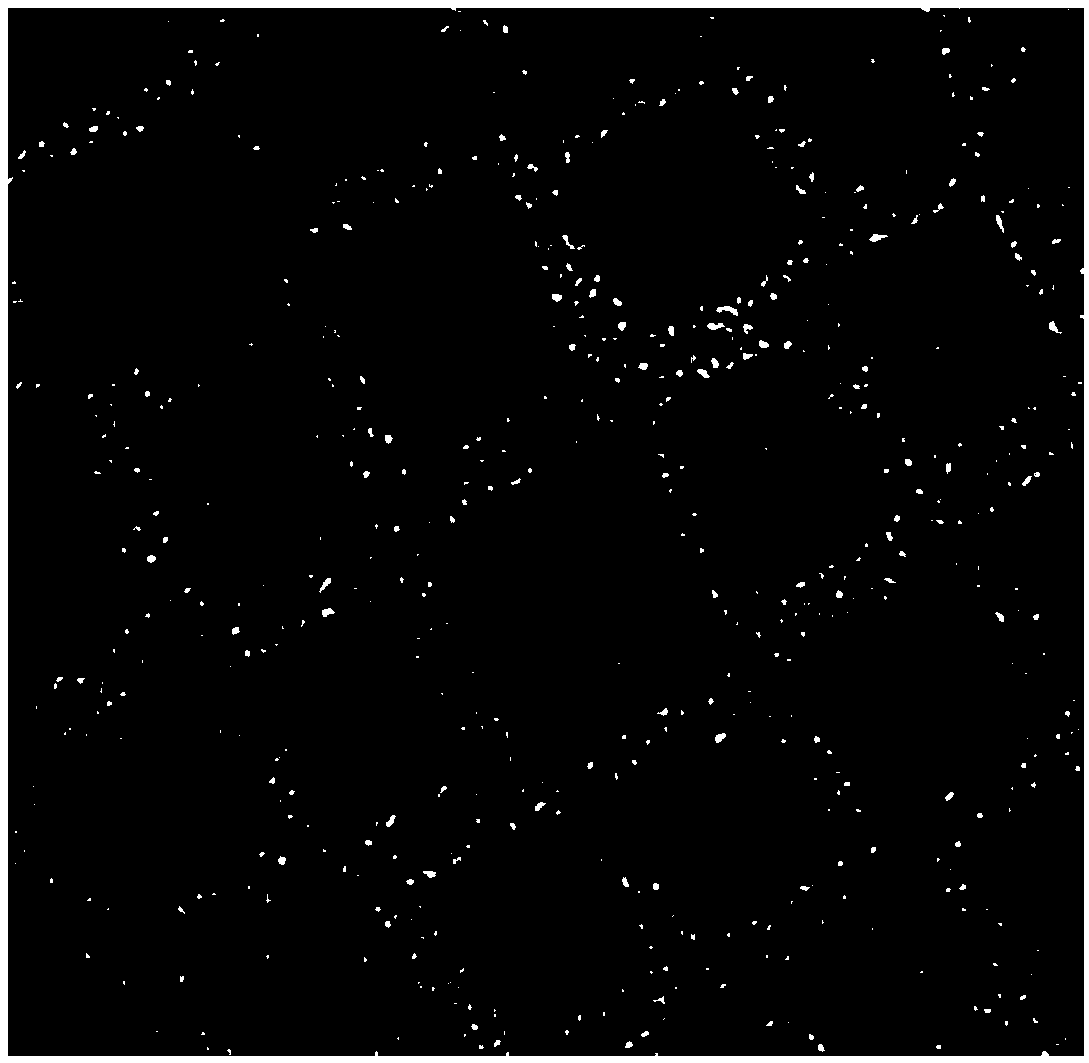

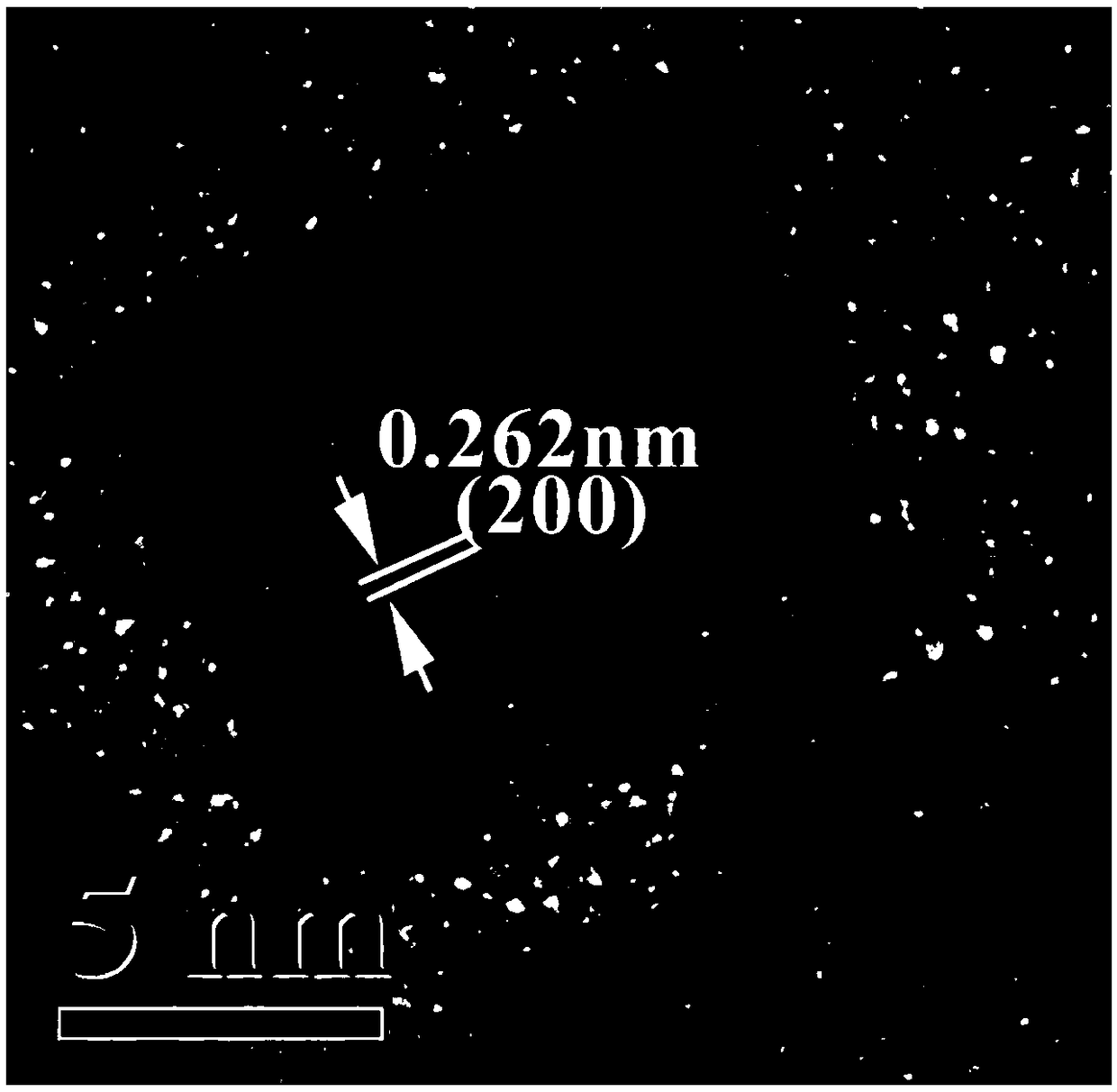

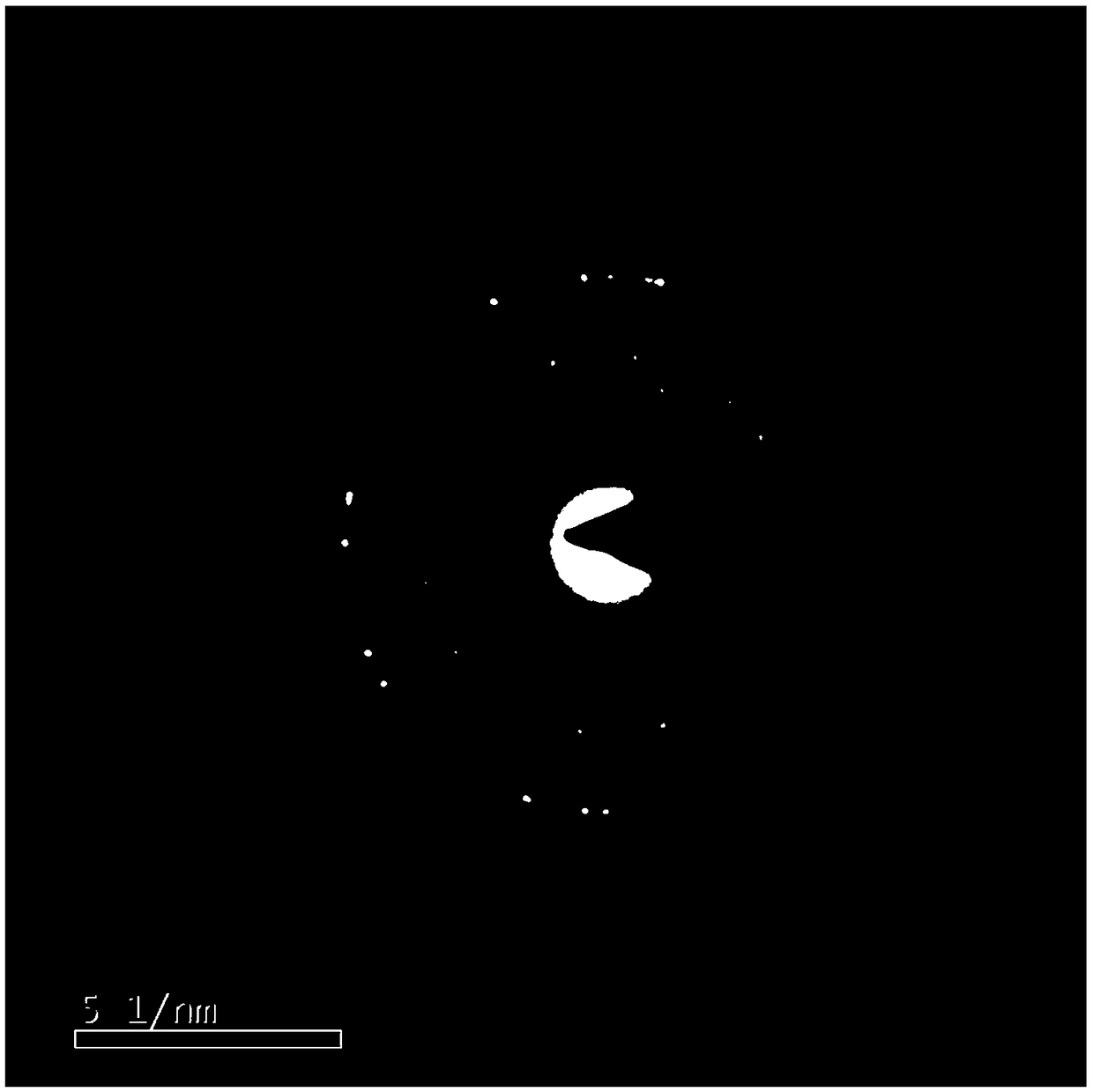

[0078] (3) Move the reaction kettle filled with about 60% of the step (2) into an oven with a constant temperature of 180 degrees Celsius, react for 24 hours and cool to room temperature, take it out, take the upper layer of brown clear liquid to obtain the tolu...

Embodiment 2

[0087] Embodiment 2, comprises the steps:

[0088] (1) Steps for configuring the modified cerium oxide solution: disperse the cerium oxide slurry described in step (11) of Example 1 in an ethanol solvent to obtain a modified cerium oxide solution.

[0089] (2) Cleaning steps: select indium-doped tin oxide (ITO) glass with a square resistance of 5-25 ohms and a transmittance of 70%-90% as the substrate, and then clean it with detergent, distilled water, ethanol and acetone in sequence , treated with oxygen plasma beam for 10 minutes after nitrogen drying;

[0090] (3) Preparation of the modified cerium oxide film: get 70 microliters of the solution described in step (1) and spin-coat it on the surface of the indium-doped tin oxide (ITO) described in step (2), at a speed of 5000 revolutions per minute After the solution was spin-coated at a high speed for 30 seconds, it was placed on a hot stage at 80 degrees Celsius and heated for 10 minutes to obtain a modified cerium oxide f...

Embodiment 3

[0101] Embodiment 3 is used to prepare a battery device for a formal planar perovskite solar cell, comprising the following steps:

[0102] (1) Cleaning steps: select indium-doped tin oxide (ITO) glass with a square resistance of 5-25 ohms and a transmittance of 70%-90% as the substrate, and then clean it with detergent, distilled water, ethanol and acetone in sequence , treated with oxygen plasma beam for 10 minutes after nitrogen drying;

[0103](2) Preparation of the electron transport layer solution: take the cerium oxide slurry described in step (11) of Example 1, disperse it in a chlorobenzene solvent at a mass concentration of 5 mg per milliliter, stir at room temperature until completely dispersed, and obtain the cerium oxide slurry Chlorobenzene solution of cerium.

[0104] (3) Preparation of the electron transport layer: get the solution described in step (2) and spin-coat it on the ITO substrate described in step (1), after spinning the solution for 30 seconds at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com