Novel SINP silicone blue-violet battery and preparation method thereof

A violet photocell and silicon-based technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of high dislocation density, decreased blue-violet light response of conventional crystalline silicon photocells, and affecting the collection efficiency of short-wavelength photogenerated carriers. To achieve the effect of improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

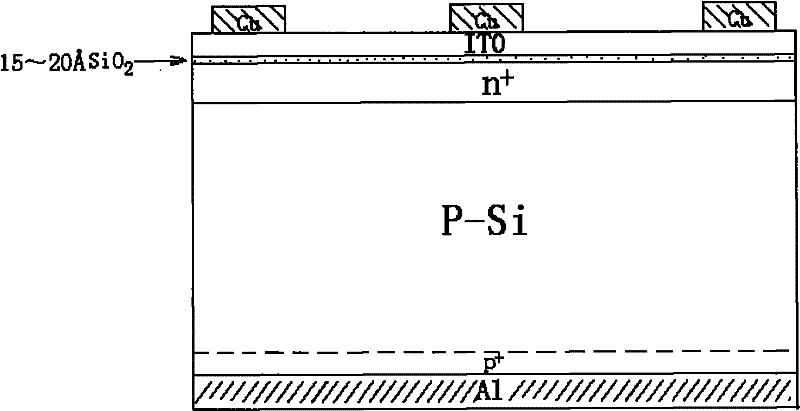

[0033] see figure 1 , the silicon-based SINP structure blue-violet light cell, including a P-type silicon single wafer substrate 1, is characterized in that a layer of n-type region 2, a layer of ultra-thin SiO 2 layer 3 and a layer of ITO anti-reflection / collection electrode film 4, Cu grid finger electrodes 5 are arranged on the surface of the ITO anti-reflection / collection film 4; a layer of Al layer (6) is provided on the back of the substrate 1.

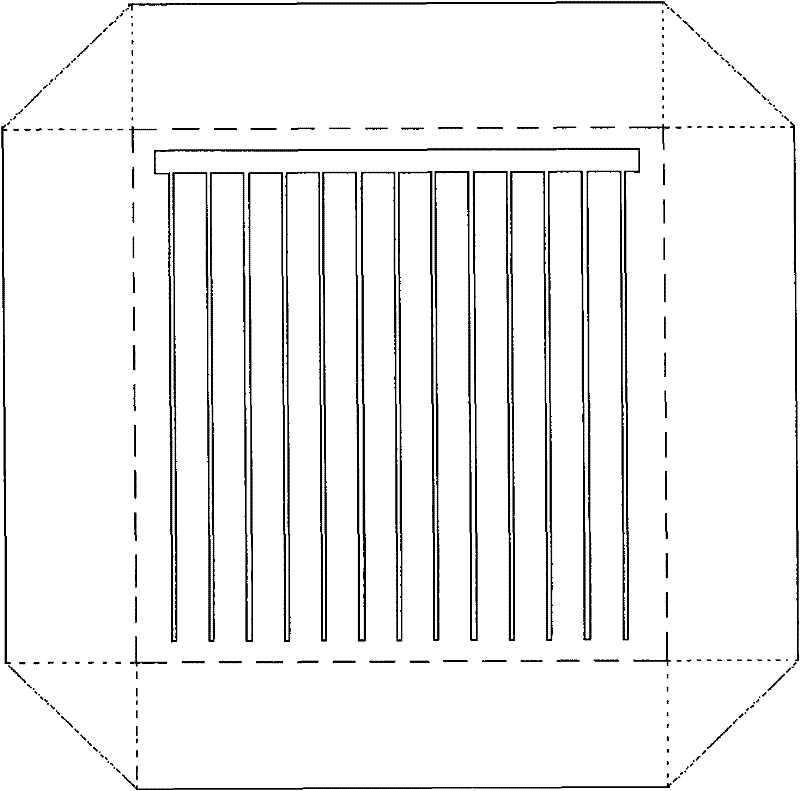

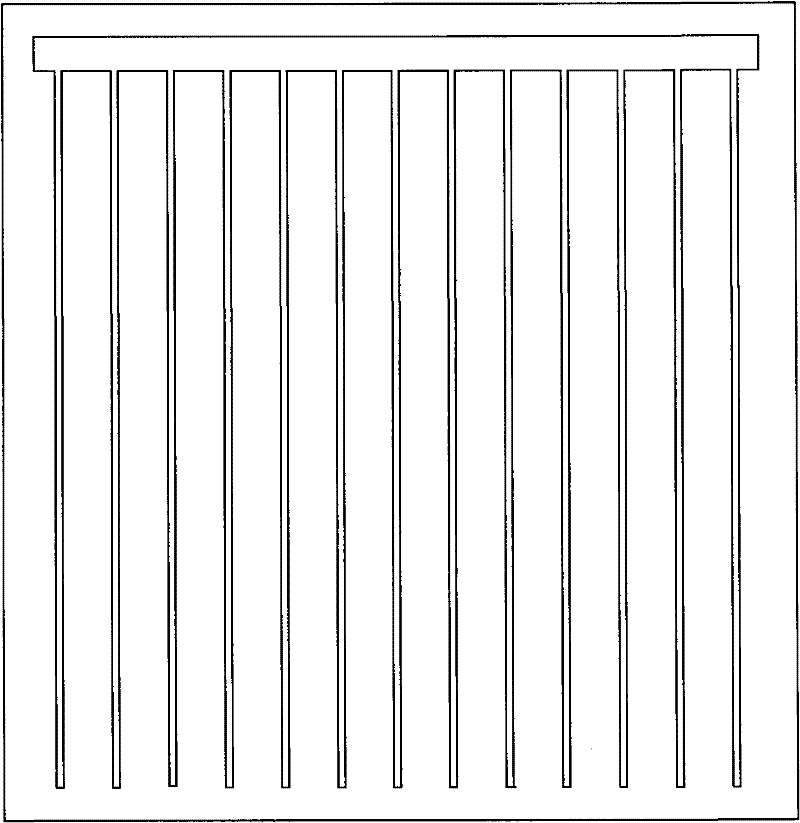

[0034] see figure 1 , Figure 2 and image 3 , the crystal orientation of the substrate 1 is (100), the resistivity is 1-2.0 Ω·cm, and the thickness is 220 μm±30 μm. The ultra-thin SiO 2 The thickness of layer 3 is 15~ The thickness of the ITO anti-reflection / collection film 4 is 70nm±7nm, and the thickness of the Cu grid finger electrode 5 is 1 μm±0.1 μm.

[0035] see figure 1 , Figure 2 and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com