Co<0.85>Se catalyst material and preparation method thereof

A catalyst and chemical catalysis technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve the problems of restricting the development of high-performance Co materials, poor controllability of morphology, and unfavorable widespread promotion, etc. The effect of easy promotion, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

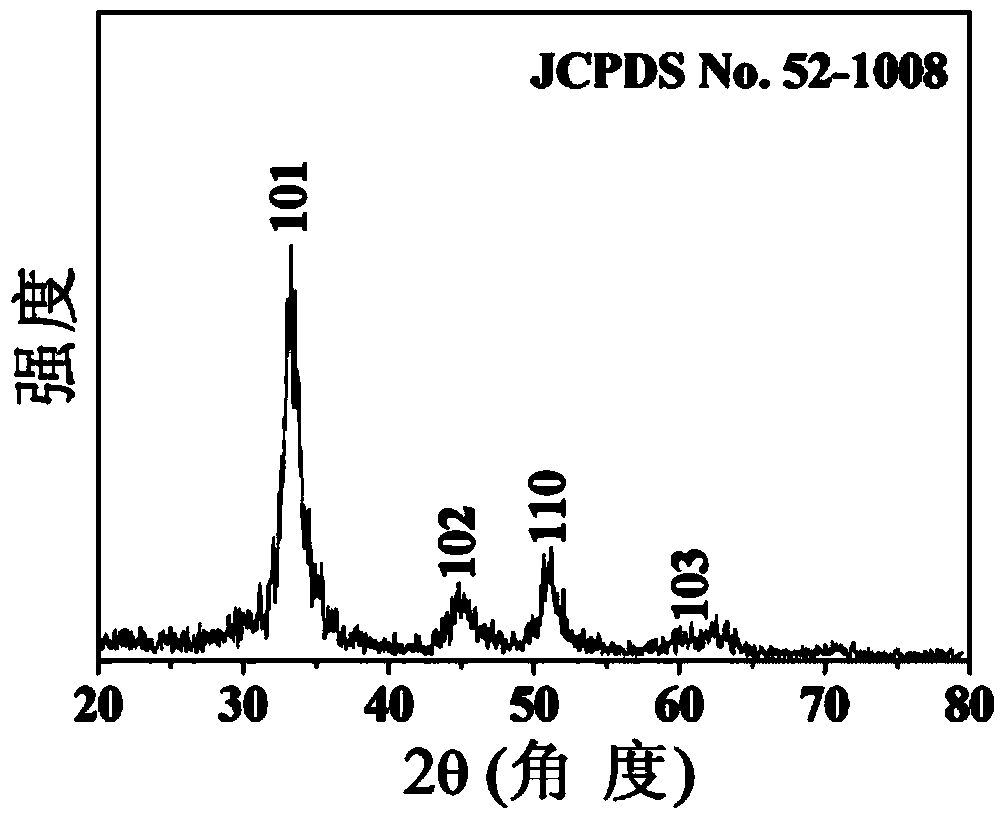

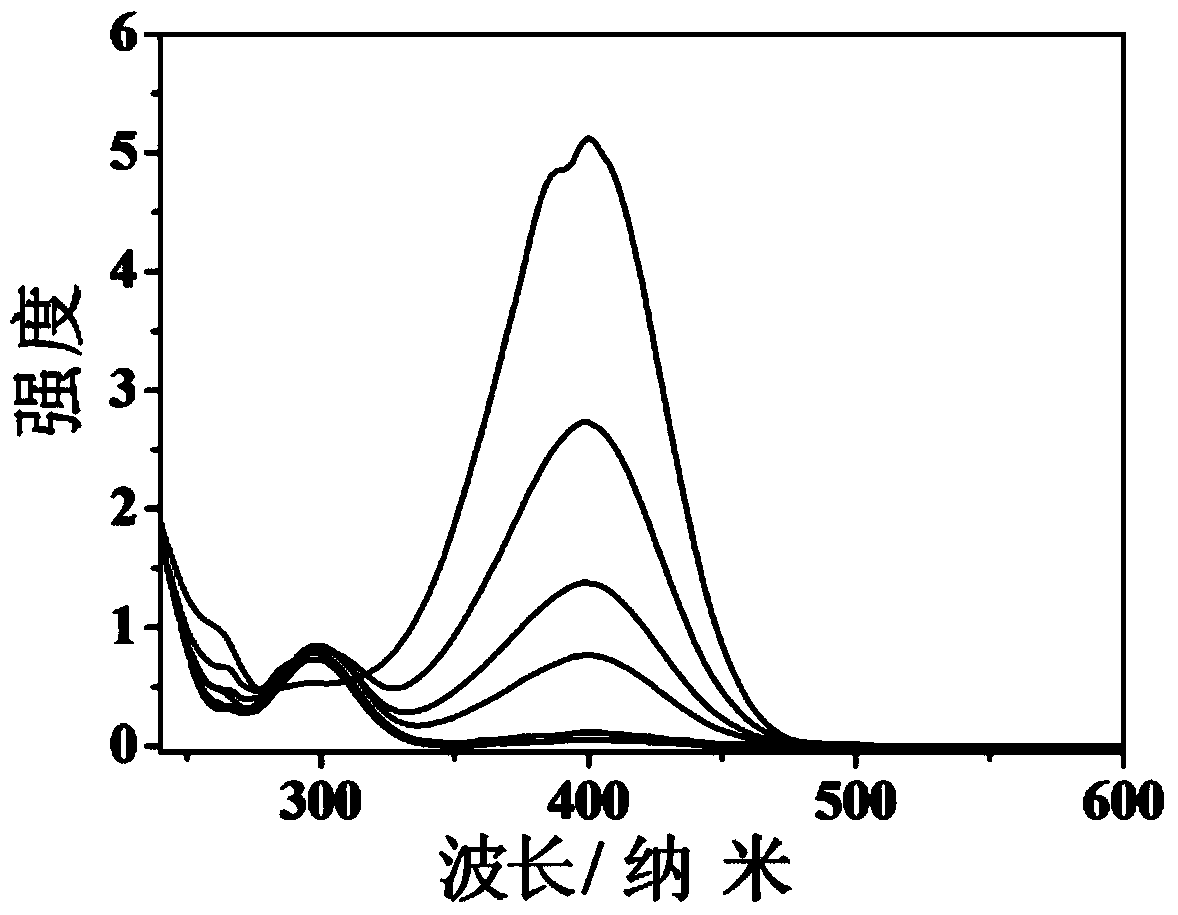

[0025] A Co 0.85 The Se catalyst material has a beam-like structure with a length of 1.0-1.8 microns and a diameter of 300-600 nanometers.

[0026] A Co 0.85 The preparation method of Se catalyst material includes the following steps:

[0027] A. Dissolve cobalt chloride and urea in a mixed solvent formed by glycerin and water, stir well to form a uniform solution, then put them into a polytetrafluoroethylene lined high pressure reactor, and react under hydrothermal conditions at 140°C for 10 After hours, the product is naturally cooled to room temperature, and the product is washed clean with deionized water and ethanol by centrifugation, and dried in vacuum at 60°C for 6 hours to constant weight, to obtain bundle Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 O precursor;

[0028] B. Weigh 100 parts by mass of the above-mentioned bunched Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 The O precursor is ultrasonically dispersed in deionized water to form a dispersion, the freshly prepared sodium hydrog...

Embodiment 2

[0033] A Co 0.85 The Se catalyst material has a beam-like structure with a length of 1.0-2.5 microns and a diameter of 350-650 nanometers.

[0034] A Co 0.85 The preparation method of Se catalyst material includes the following steps:

[0035] A. Dissolve cobalt chloride and urea in a mixed solvent of glycerin and water, stir well to form a uniform solution, then put them into a polytetrafluoroethylene lined high pressure reactor, and react at 160℃ for 8 hours under hydrothermal conditions , And then naturally cooled to room temperature, the product was washed clean with deionized water and ethanol by centrifugation, and dried in vacuum at 60°C for 6 hours to constant weight to obtain bundle Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 O precursor;

[0036] B. Weigh 100 parts by mass of the above-mentioned bunched Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 The O precursor is ultrasonically dispersed in deionized water to form a dispersion, the freshly prepared sodium hydrogen selenide is added dro...

Embodiment 3

[0039] A Co 0.85 The Se catalyst material has a beam-like structure with a length of 1.2-2.5 microns and a diameter of 400-720 nanometers.

[0040] A Co 0.85 The preparation method of Se catalyst material includes the following steps:

[0041] A. Dissolve cobalt chloride and urea in a mixed solvent of glycerin and water, stir well to form a uniform solution, then put them into a polytetrafluoroethylene lined high pressure reactor, and react at 200°C for 3 hours under hydrothermal conditions , And then naturally cooled to room temperature, the product was washed clean with deionized water and ethanol by centrifugation, and dried in vacuum at 60°C for 6 hours to constant weight to obtain bundled Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 O precursor;

[0042] B. Weigh 100 parts by mass of the above-mentioned bunched Co(OH) 1.1 (CO 3 ) 0.35 Cl 0.2 ·NH 2 The O precursor is ultrasonically dispersed in deionized water to form a dispersion, the freshly prepared sodium hydrogen selenide is added d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com