High-voltage positive electrode material precursor, lithium battery positive electrode material prepared therefrom, and preparation method

A positive electrode material and precursor technology, applied in the field of lithium-ion battery electrode materials, to achieve high volume specific energy, low-cost competitive advantage, and improve the effect of surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Add 15L of deionized water, turn on the stirring paddle, and heat to 45-47°C to prepare 200L of a feed solution with a total concentration of nickel-manganese-cobalt of 1.8mol / L and a ratio of nickel-manganese-cobalt of 6:2:2. Add 10L of 170g / L ammonia solution to the prepared feed solution to obtain a mixed solution, and simultaneously pass the mixed solution and 9mol / L sodium hydroxide solution into the reactor for reaction, and control the pH value in the reactor to 10.5 ~11.0, the reaction temperature is 45~47℃.

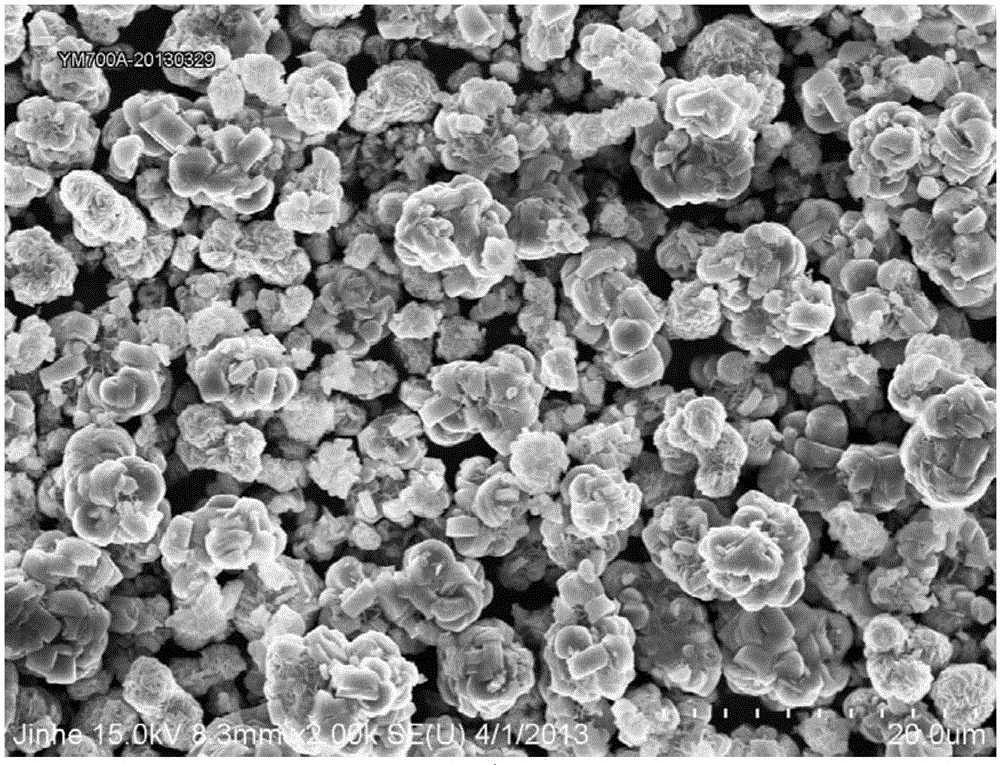

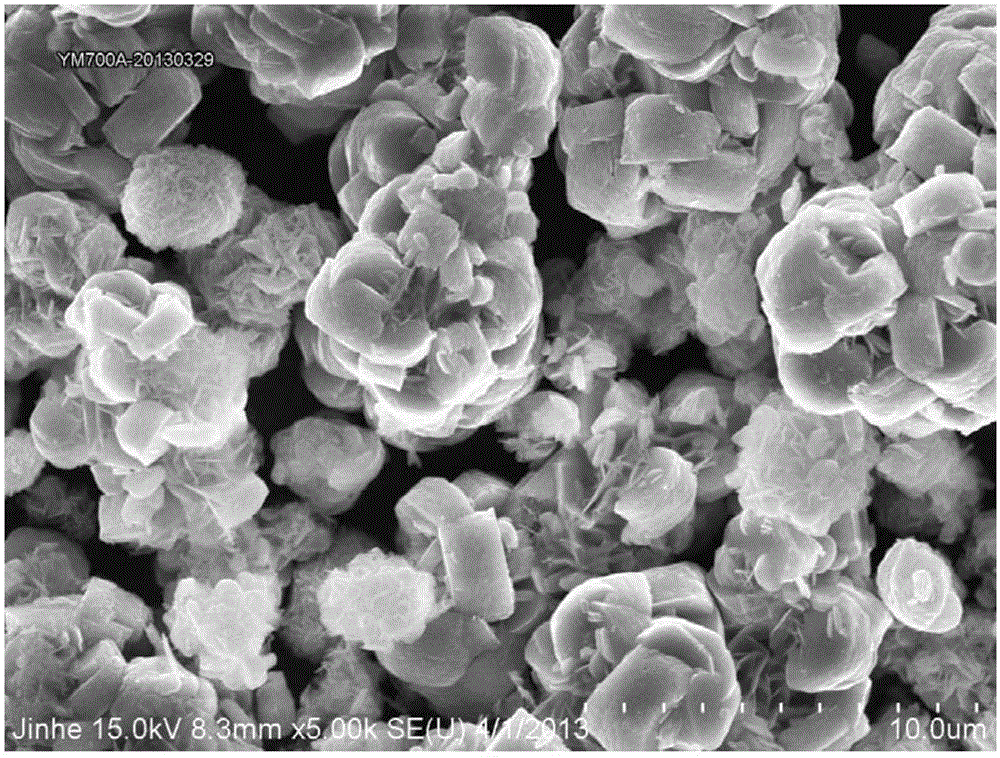

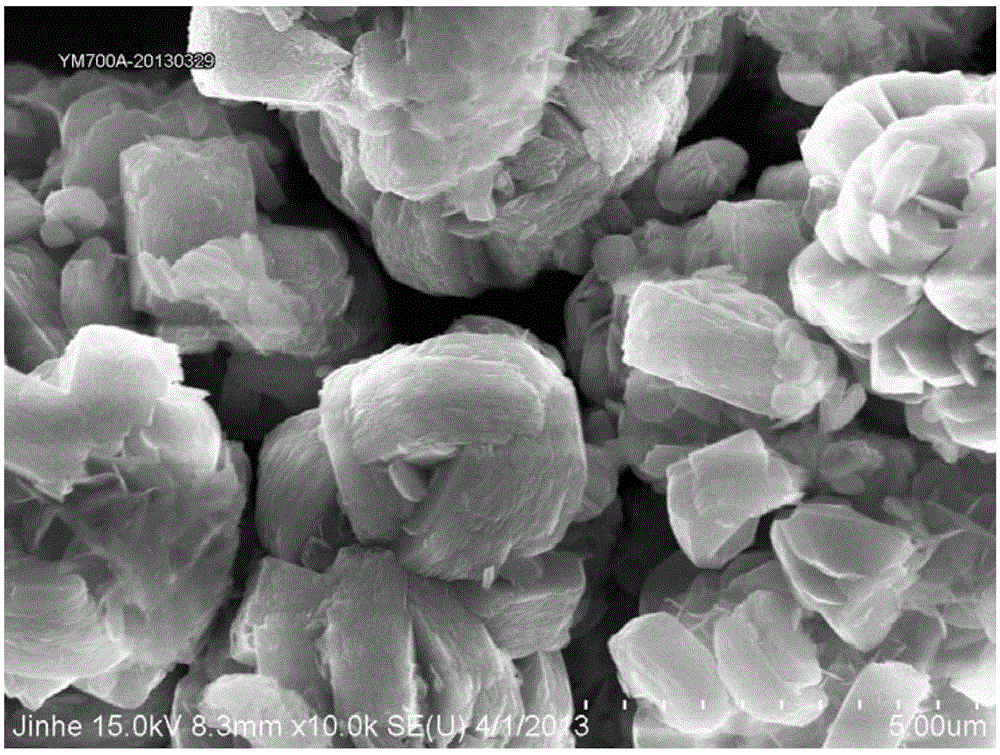

[0041] After feeding the feed liquid, continue to raise the pH to 12.5 by sodium hydroxide solution, keep it warm at 85-95°C and age for 24 hours. The obtained product is subjected to solid-liquid separation, and the solid product is washed with deionized water to The pH value is 7.5, and the washed product is dried in a dryer at 80-120°C to obtain the molecular formula Co 0.2 mn 0.2 Ni 0.6 (OH) 2 Nickel-based material with a large primary particle siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com