Rare-earth-ion-doped LiGdI4 microcrystalline glass and preparation method thereof

A technology of glass-ceramic and rare-earth ions is applied in the field of rare-earth ion-doped LiGdI4 glass-ceramic and its preparation. Low production cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Table 1 shows the glass formula and the first crystallization temperature value of Embodiment 1.

[0022] Table 1

[0023]

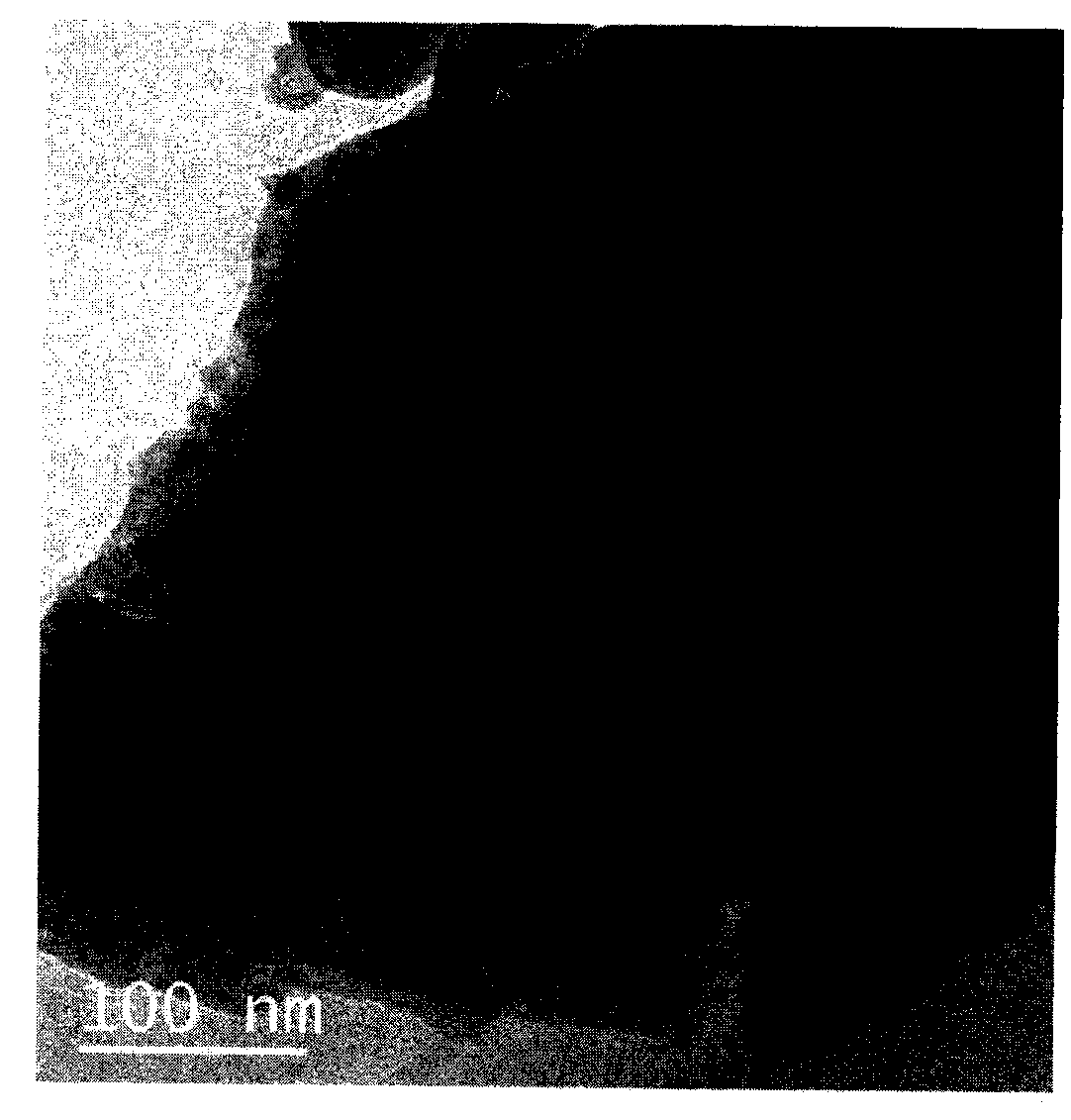

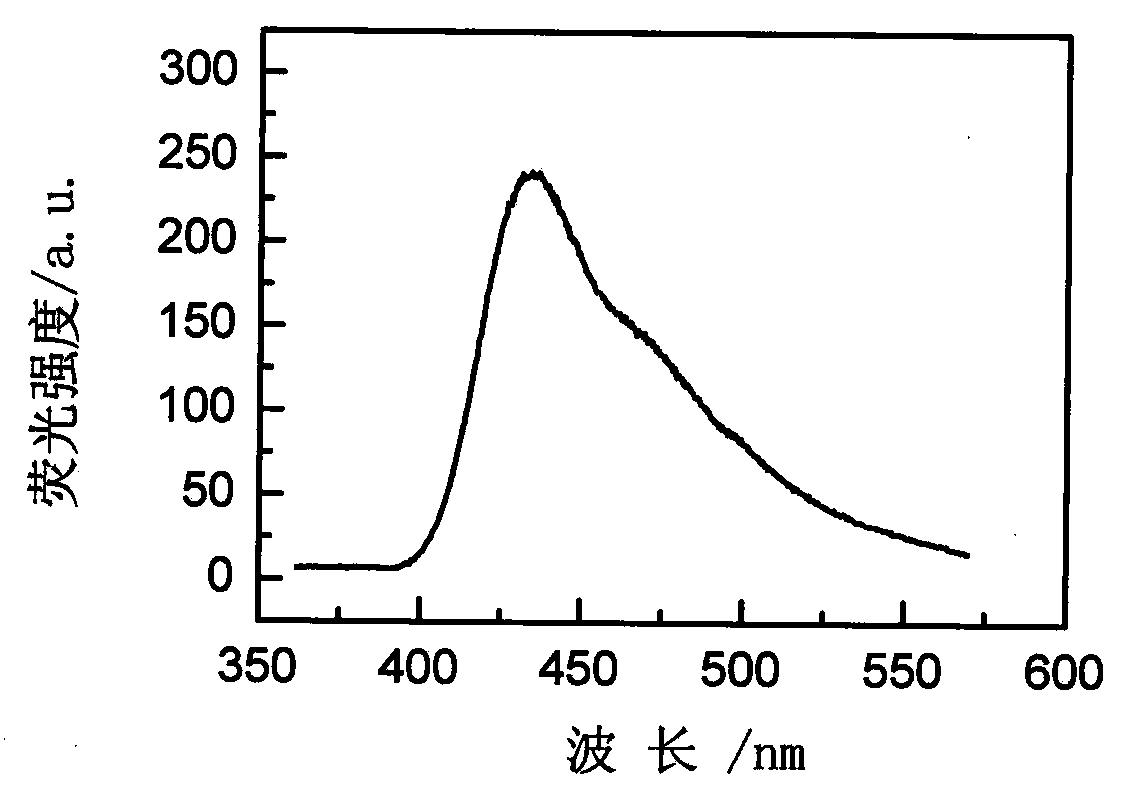

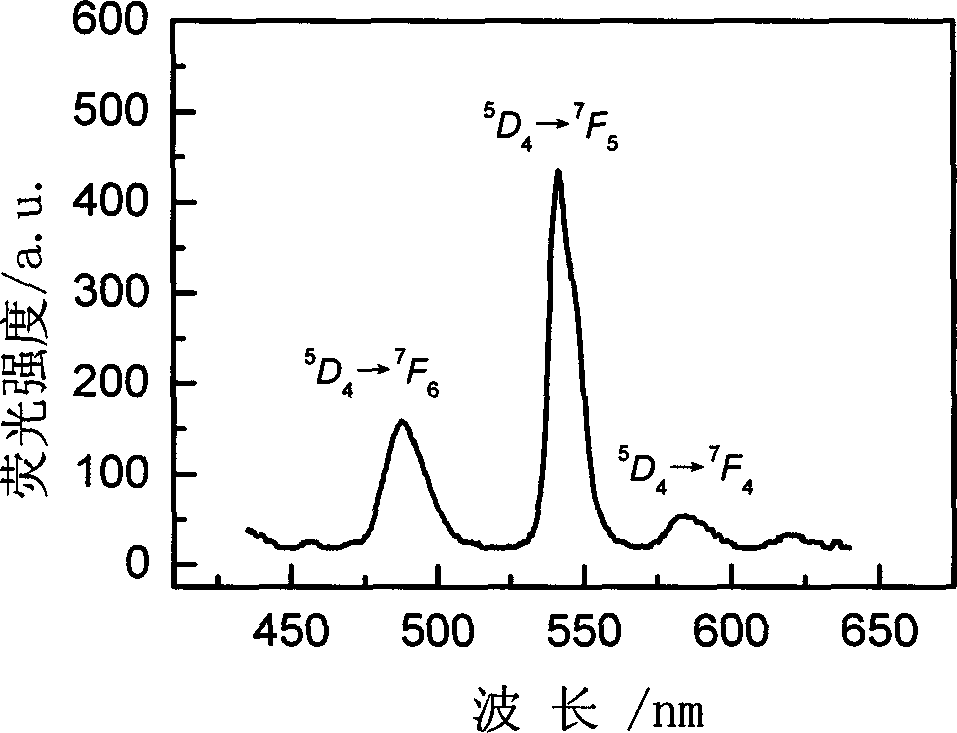

[0024] The specific preparation process is as follows: in the first step, weigh 50 grams of analytically pure raw materials according to the formula in Table 1, add 2.5 grams of NH 4 HF 2 , 2.5 g NH 4 HI 2 , mix the raw materials evenly and pour them into a quartz crucible to melt, the melting temperature is 800°C, keep warm for 2 hours, pour the glass melt into a cast iron mold, then place it in a muffle furnace for annealing, and keep warm at the glass transition temperature Tg for 1 Hours later, cool down to 50°C at a rate of 10°C / hour, turn off the power supply of the muffle furnace to automatically cool down to room temperature, and take out the glass; in the second step, according to the thermal analysis (DTA) experimental data of the glass, the first crystallization temperature of 445 ℃, heat-treat the prepared glass in...

Embodiment 2

[0026] Embodiment 2: Table 2 shows the glass formula and the first crystallization temperature value of Embodiment 2.

[0027] Table 2

[0028]

[0029] The specific preparation process is as follows: in the first step, weigh 50 grams of analytically pure raw materials according to the formula in Table 2, add 2.5 grams of NH 4 HF 2 , 2.5 g NH 4 HI 2 , Mix the raw materials evenly and pour them into a corundum crucible for melting, the melting temperature is 850°C, keep warm for 1 hour, pour the glass melt into a cast iron mold, then place it in a muffle furnace for annealing, and keep warm at the glass transition temperature Tg for 1 hour Hours later, cool down to 50°C at a rate of 10°C / hour, turn off the power supply of the muffle furnace to automatically cool down to room temperature, and take out the glass; in the second step, according to the experimental data of thermal analysis (DTA) of the glass, the first crystallization temperature of 450 ℃, heat-treat the prep...

Embodiment 3

[0031] Embodiment 3: Table 3 shows the glass formula and the first crystallization temperature value of Embodiment 3.

[0032] table 3

[0033]

[0034] The specific preparation process is as follows: in the first step, weigh 50 grams of analytically pure raw materials according to the formula in Table 3, add 2.5 grams of NH 4 HF 2 , 2.5 g NH 4 HI 2 , mix the raw materials evenly and pour them into a quartz crucible to melt at a melting temperature of 900°C and keep it warm for 1.5 hours. Hours later, the temperature was lowered to 50° C. at a rate of 10° C. / hour, the power of the muffle furnace was turned off and the temperature was automatically lowered to room temperature, and the glass was taken out. In the second step, according to the glass thermal analysis (DTA) experimental data, the first crystallization temperature is 453°C, and the prepared glass is placed in a nitrogen precision annealing furnace for heat treatment at 472°C for 5 hours, and then at 5°C / hour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com