Rock soil curing agent and preparation method thereof

A solidifying agent and geotechnical technology, applied in the field of geotechnical solidifying agent and its preparation, can solve the problems of restricting the use of geotechnical solidifying agents, great differences in solidification performance, and lack of pertinence and compatibility of solidifying agents, so as to reduce construction costs. Road cost, little difference in curing performance, and the effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

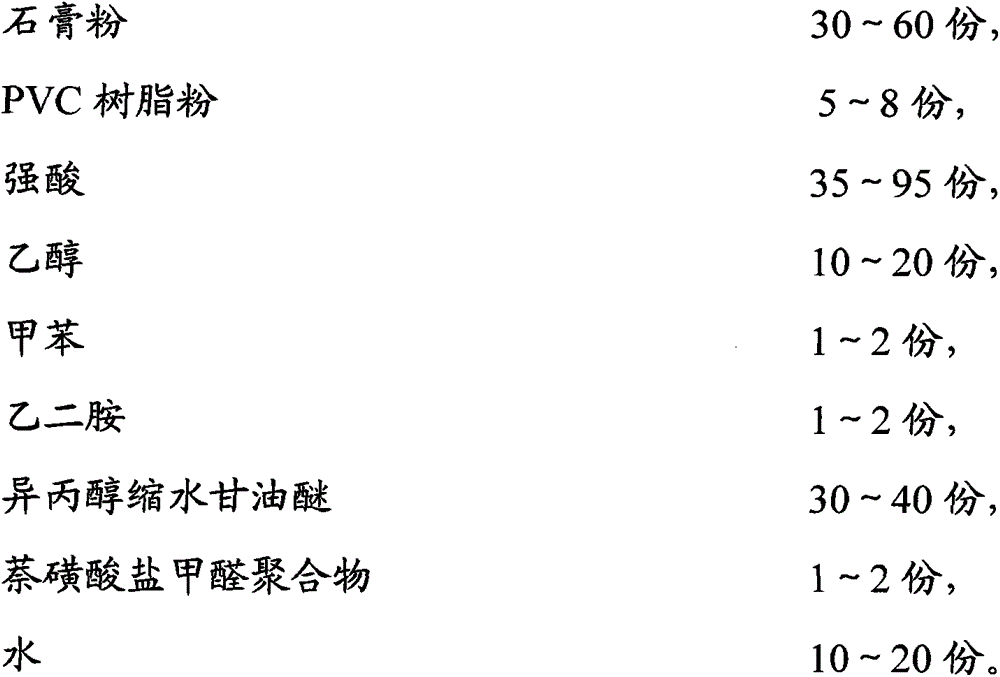

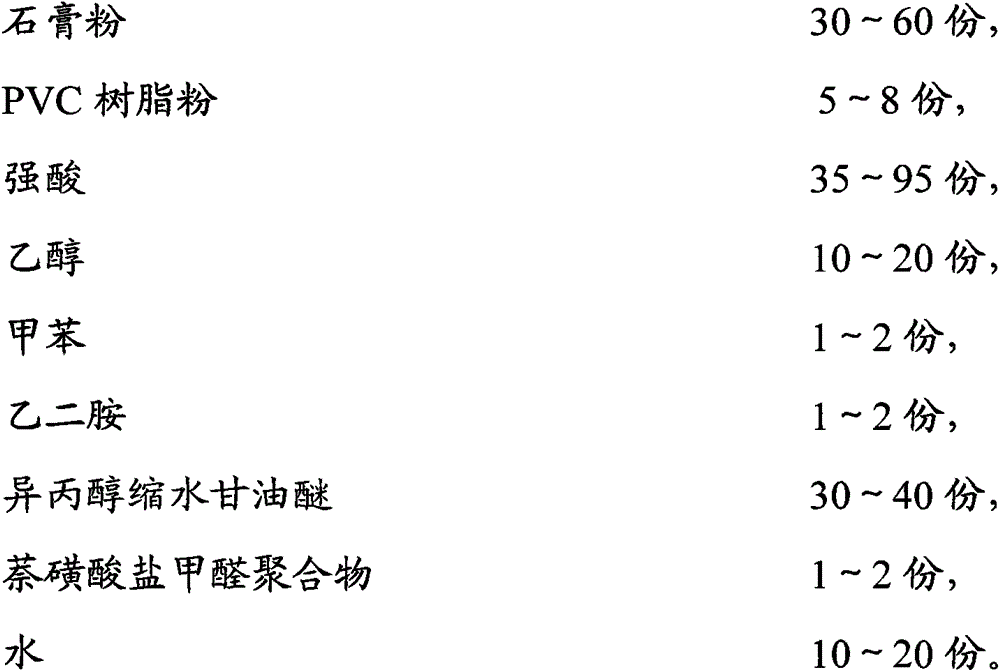

[0019] (1) Mix 5kg PVC resin powder, 20kg ethanol, and 10kg water and stir evenly to obtain mixed solution 1;

[0020] (2) 2kg of toluene, 1kg of ethylenediamine, 40kg of isopropanol glycidyl ether, and 1kg of naphthalenesulfonate formaldehyde polymer were slowly added to 95kg of concentrated hydrochloric acid and stirred evenly to obtain a mixed solution 2;

[0021] (3) Mix the mixed solution 1 and the mixed solution 2 to obtain the mixed solution 3, add 30 kg of gypsum powder into the mixed solution 3 and stir evenly to obtain the rock solidification agent 1.

[0022] (4) cement is added in the soil by its weight ratio with soil as 5: 95, according to the natural water content of soil is 9%, calculates if will reach optimal water content 11% in cement and waste gas weathering rock-soil mixture, Then it is necessary to add 2% of the water amount accounting for the total weight of the cement and the waste gas weathered rock-soil mixture, and then add the rock-soil solidifying ...

Embodiment 2

[0024] (1) Mix 8kg PVC resin powder, 10kg ethanol, and 20kg water and stir evenly to obtain mixed solution 1;

[0025] (2) 1kg of toluene, 2kg of ethylenediamine, 30kg of isopropanol glycidyl ether, and 2kg of naphthalenesulfonate formaldehyde polymer were slowly added to 35kg of concentrated hydrochloric acid and stirred evenly to obtain a mixed solution 2;

[0026] (3) Mix the mixed solution 1 and the mixed solution 2 to obtain the mixed solution 3, add 60 kg of gypsum powder into the mixed solution 3 and stir evenly to obtain the rock solidification agent 2.

[0027] (4) crushing the earth-encrusted rock, making the particle diameter of the earth-encrusted stone after crushing less than 3 centimeters, then adding cement and lime to the earth-entrained rock in a weight ratio of 5:5:90, According to the natural moisture content of the soil intercalation stone is 4%, it is calculated that if the optimum water content of 9% is to be achieved in the mixture of cement, lime and s...

Embodiment 3

[0029] (1) Mix 6kg PVC resin powder, 15kg ethanol, and 15kg water and stir evenly to obtain mixed solution 1;

[0030] (2) 1kg of toluene, 2kg of ethylenediamine, 35kg of isopropanol glycidyl ether, and 1kg of naphthalenesulfonate formaldehyde polymer were slowly added to 50kg of concentrated hydrochloric acid and stirred evenly to obtain a mixed solution 2;

[0031] (3) The mixed solution 1 and the mixed solution 2 were mixed to obtain a mixed solution 3, and 40 kg of gypsum powder was added to the mixed solution 3 and stirred evenly to obtain a rock solidification agent 3.

[0032] (4) The mixture of loess and weathered rock is crushed so that the particle size of the broken loess and weathered rock is less than 3 cm, and then lime is added to the mixture in a weight ratio of 6:94, according to The natural water content of mixture is 12%, calculates if will reach optimum water content 16% in weathered rock and lime mixture, then need add and account for weathered rock and li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com