Cardanol modified phenolic resin for glass fiber reinforced plastic laminated materials and preparation method thereof

A fiberglass layer and phenolic resin technology, applied in the field of phenolic resin, can solve the problems of high cost of polyvinyl butyral, unfavorable resin storage stability, Na ion residue, etc., and achieve easy polishing, low cost, pure and transparent color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

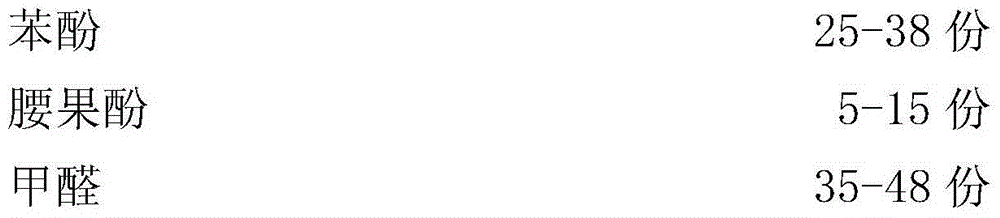

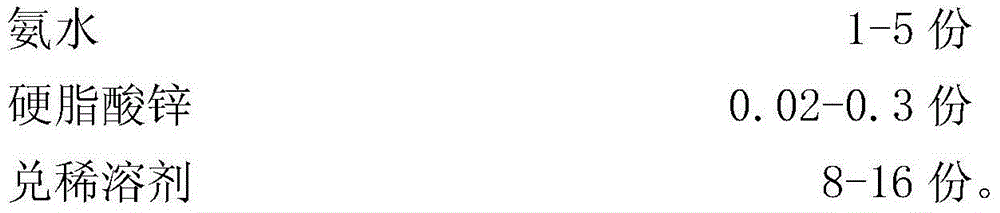

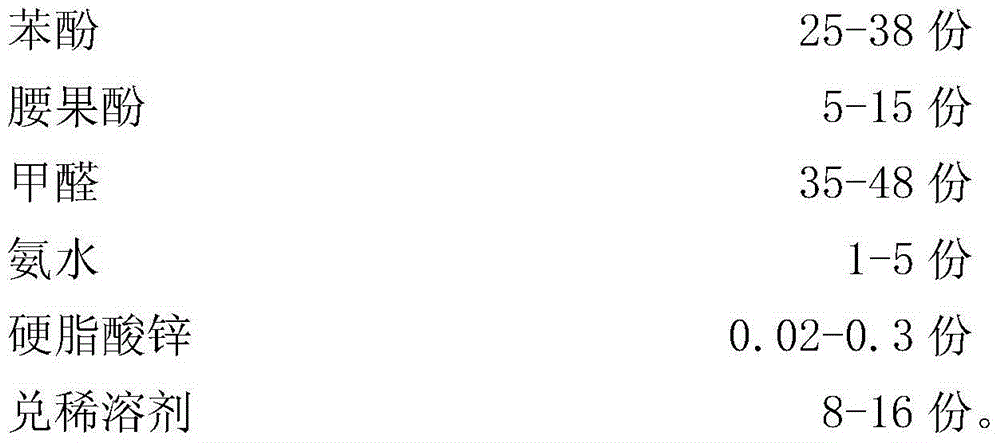

[0021] A cardanol-modified phenolic resin for fiberglass laminated materials, which is formulated by the following components in parts by weight:

[0022]

[0023] The above-mentioned preparation method of the cardanol-modified phenolic resin used for FRP laminates is prepared according to the following method:

[0024] (1), phenol, cardanol, formaldehyde are added in reaction container, be heated up to 65-70 ℃ and stir evenly;

[0025] (2) Add ammonia water and react at a temperature of 80-85°C for 0.5-1.5 hours;

[0026] (3) After dehydration, add zinc stearate, then add dilute solvent and dilute to 50-60% solid content and then discharge.

[0027] The diluted solvent in the above components is one or any combination of ethanol, methanol, and n-butanol, wherein the volume concentration of ethanol is 95%, the mass fraction of methanol is 98%-99%, and the mass fraction of n-butanol is 99.9%. The phenol is phenol produced by Shanghai Gaoqiao Chemical Industry. The cardano...

Embodiment 1

[0029] Embodiment 1: a kind of cardanol-modified phenolic resin that is used for FRP laminated material, it is formulated by following components by weight and number ratio:

[0030]

[0031] A preparation method for a cardanol-modified phenolic resin for fiberglass laminates, prepared according to the following method:

[0032] (1), after preparing the materials, add phenol, cardanol, and 37% formaldehyde solution to the reaction kettle successively, heat up to 65°C, and stir evenly;

[0033] (2), add 20% ammonia solution, stop heating and stirring, rely on the exothermic reaction to heat up to 82 ° C, and keep warm for 0.5 hours;

[0034] (3), turn on the vacuum pump to depressurize to 0.8MPa for dehydration, add zinc stearate after dehydration, then dilute with ethanol to 50% solid content, and discharge.

[0035] Through the test of present embodiment, the present invention is used for the cardanol-modified phenolic resin of FRP laminated material each technical perfor...

Embodiment 2

[0037] Embodiment 2: a kind of cardanol-modified phenolic resin that is used for FRP laminated material, it is formulated by following components by weight and number ratio:

[0038]

[0039] A preparation method for a cardanol-modified phenolic resin for fiberglass laminates, prepared according to the following method:

[0040] (1), after preparing the materials, add phenol, cardanol, and 37% formaldehyde solution to the reaction kettle successively, heat up to 65°C, and stir evenly;

[0041] (2), add 20% ammonia solution, stop heating and stirring, rely on the exothermic reaction to heat up to 80°C, and keep the temperature for 1 hour;

[0042] (3), turn on the vacuum pump to depressurize to 0.8MPa for dehydration, add zinc stearate after dehydration, then dilute with n-butanol to 52% solid content, and discharge.

[0043] Through the test of present embodiment, the present invention is used for the cardanol-modified phenolic resin of FRP laminated material each technica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com