Etching liquid and method for etching fine lines of flexible circuit board by using same

A flexible circuit board and etching solution technology, which is applied in the field of etching solution and flexible circuit board thin line etching, can solve the problems of relatively long equipment length design, low production efficiency, and slow etching rate, etc. Side etching and the effect of increasing the etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

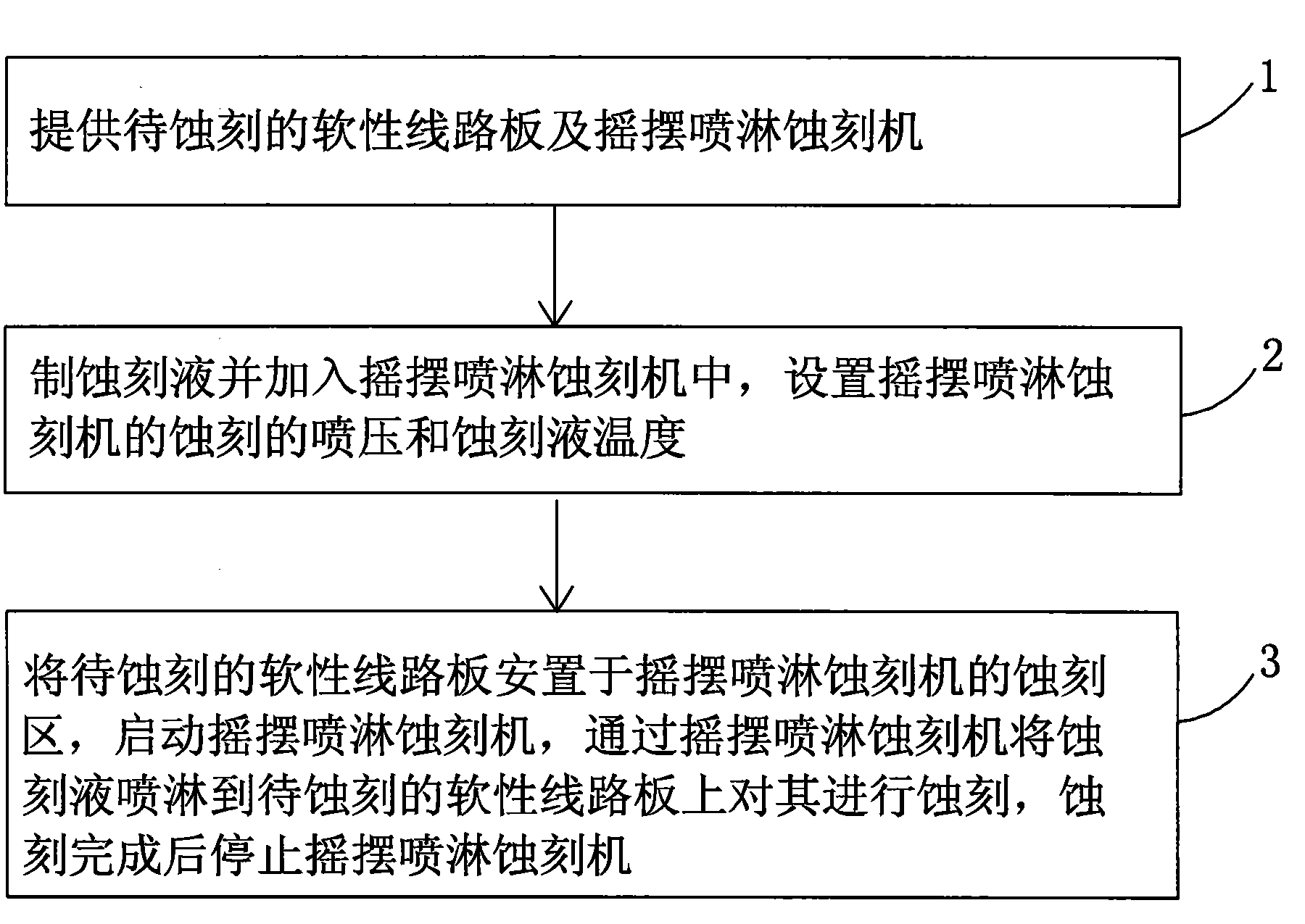

[0040] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0041] The invention provides a kind of etching liquid, uses water as solvent, comprises solute and each solute concentration is as follows:

[0042] Copper chloride dihydrate, 130-250g / L;

[0043] 30% hydrochloric acid, 100-150mL / L;

[0044] Ammonium chloride, 26.7-128.4g / L;

[0045] Bank revetment agent, 0.5-16g / L;

[0046] Auxiliary solvent, 2-6g / L.

[0047] Wherein the bank protection agent is a corrosion inhibitor, such as mercaptobenzothiazole, benzotriazole, tolyltriazole, etc., and the corrosion inhibitor can form a protective film on the surface of the copper foil of the flexible circuit board. Benzotriazole is preferably used as a bank revetment agent in this embodiment. The auxiliary solvent is polyhydric alcohol, which has ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com