A soilless board for rice seedling raising and its application in the field of rice soilless machine transplanting

A technology for raising rice seedlings and soil slabs is applied in the directions of application, soilless cultivation, botanical equipment and methods, etc., and can solve the problems of unfavorable large-scale mechanized production and application, labor-intensive preparation of rice seedlings, complicated operation procedures, etc. Industrialization development, reduction of void rate and seedling injury rate, and the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Material preparation

[0040] 1.1 Operation location: It was carried out at the Danyang Experimental Base of Nanjing Agricultural University (32°00′N, 119°32′E, 7masl) from 2011 to 2013.

[0041] 1.2 Materials: Rice husks produced by Yanfeng Rice Processing Factory, Yanling Town, Danyang City, commercially available non-woven fabrics

[0042] 1.3 Selection of rice species: conventional japonica rice Wuyunjing No. 24, 1,000-grain weight 27g.

[0043] 2. Operation steps

[0044] 2.1 Production of rice seedling-free soil board

[0045] In 2011, choose different densities (10g / m2) from all over the country 2 , 20g / m 2 、30g / m 2 ), non-woven fabrics of different production processes (spunbonded non-woven fabrics, melt-blown non-woven fabrics, water-repellent non-woven fabrics), and sponges are used as covering layers to cover the seedling trays evenly, with a thickness of 1.0cm. Above the rice husk of the bottom layer, ensure that the covering layer is flat and complet...

Embodiment 2

[0063] 1. Material preparation as in Example 1

[0064] 2. Operation steps

[0065] 2.1 Production of rice seedling-free soil board

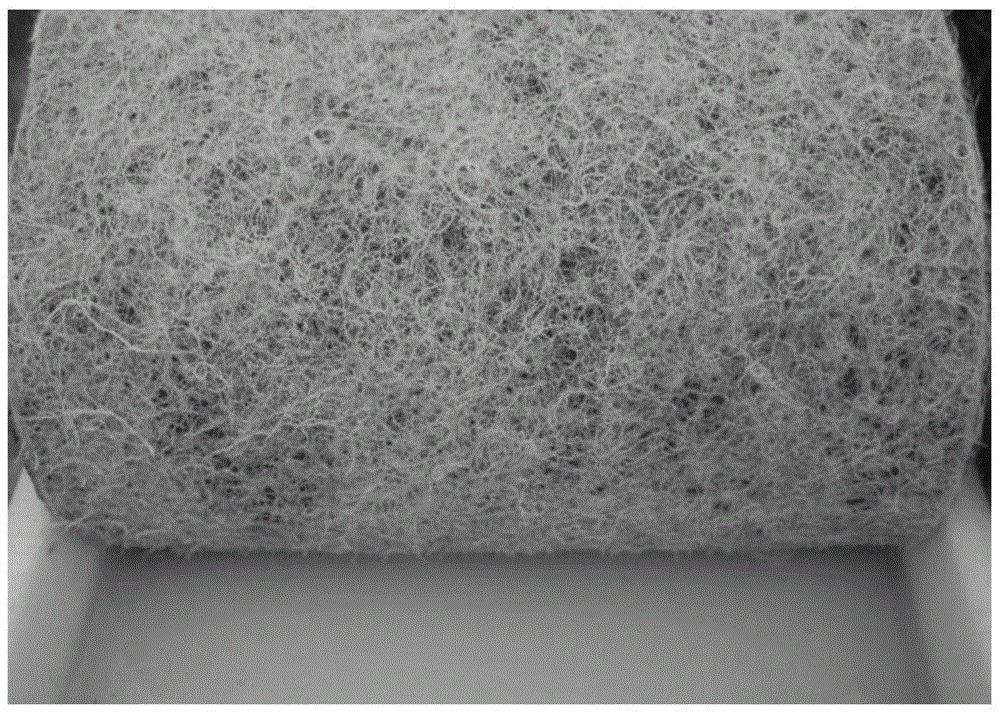

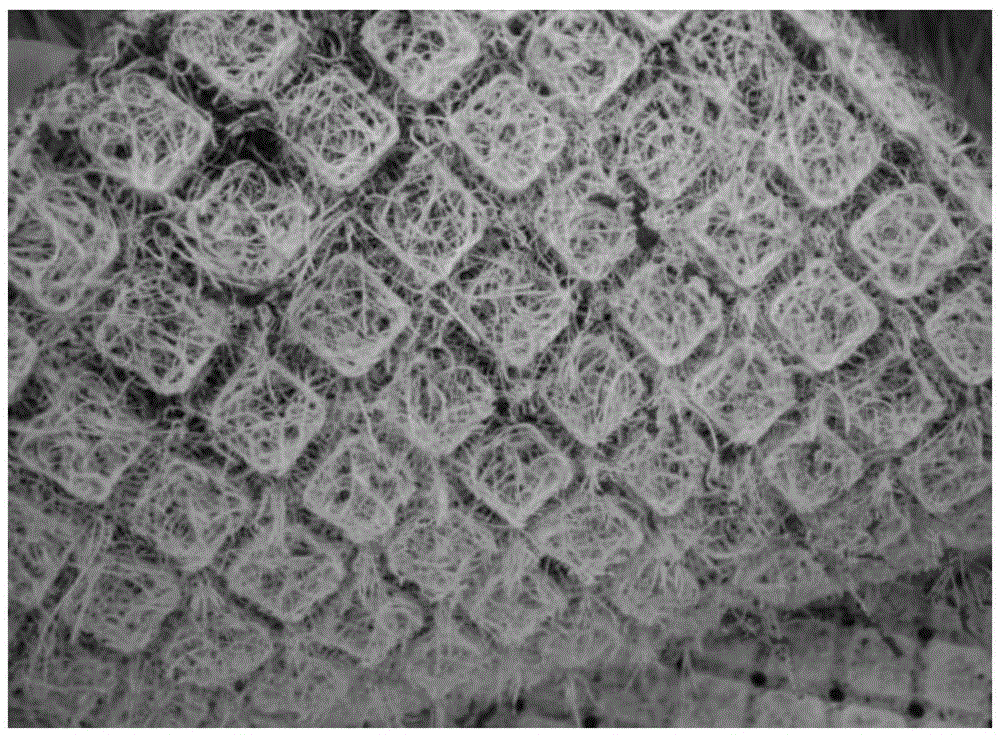

[0066] In 2012 and 2013, 1.5 cm of rice husks were evenly spread on the seedling trays to ensure that the rice husks were evenly distributed on the seedling trays and had a consistent thickness. Among them, the specification of the seedling tray is height*width*length 0.05m*1.2m*3m, which is composed of four seedling troughs as a whole, and the height*width*length of each seedling trough is 0.05m*0.28m*3m. Choose 20g / m with better effect in 2011 2 The spunbonded non-woven fabric is covered on the rice husk (structural levels such as Figure 6 shown), measured according to the traditional seedling tray (28cm×58cm×3cm), the rice seed sowing rate is 120g, and it is marked as LMSH group.

[0067] Conventional nutrient soil was used as a medium to form a traditional seedling-raising plate as the control group CK1, in which the seedling-raising pl...

Embodiment 3

[0085] 1. Material preparation as in Example 1

[0086] 2. Operation steps

[0087] 2.1 Production of rice seedling raising board

[0088] In 2012 and 2013, 0.5cm of rice husk was evenly spread on the seedling tray as the base layer. The specification of the seedling tray was height*width*length 0.05m*1.2m*6m. The height*width*length is 0.05m*0.28m*6m, choose 20g / m with better effect in 2011 2 The spunbonded non-woven fabric is used as a covering layer to cover the rice husk (the structure level is as follows: Figure 6 shown), labeled as LMSH group.

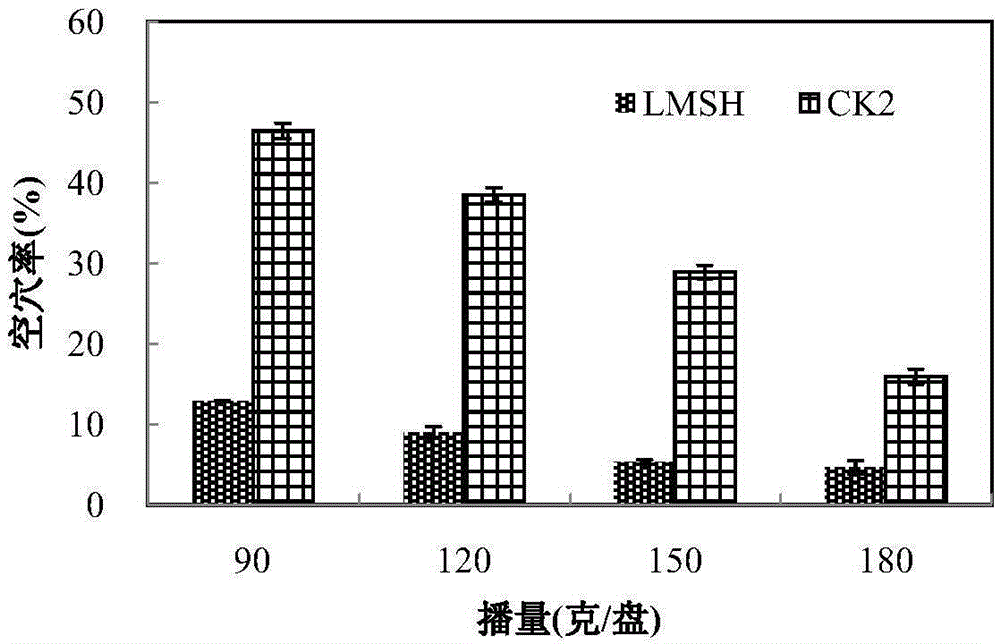

[0089] The seedling-raising board formed with non-woven fabric as the seedling-raising medium was used as the control group CK2, that is, the seedling-raising board used 20g / m 2 The spunbonded non-woven fabric does not use rice husk as the medium, and the specification of the seedling tray is the same as that provided by the above-mentioned LMSH group in this embodiment. The operations of the two groups are managed in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com