Preparation method of weikang capsule

A technology of Weikang capsules and process steps, which is applied in the field of preparation of Weikang capsules, can solve the problems of longer production cycle, longer time for active ingredient absorption, higher production costs, etc., to achieve easy crushing, avoid heat softening and stickiness, Effect of reducing volatile loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

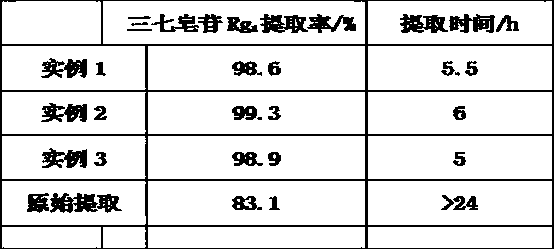

Examples

Embodiment 1

[0019] 1. Take 64g of Baiji, 63g of squid octopus, 38g of gallinaceous gold, 1g of egg shell (scrambled) and 13g of Baicao cream, and carry out ultrafine grinding, pass through a 200-300 mesh sieve, and make ultrafine powder for later use;

[0020] 2. Take 63g of frankincense and 15g of myrrh to pulverize with an ultra-low temperature pulverizer, pass through a 180-300 mesh sieve, and make superfine powder for later use;

[0021] 3. Take 64g of Panax notoginseng and 64g of Rhizoma Cyperi, crush them into fine powder, add 65% ethanol, conduct ultrasonic continuous countercurrent extraction for 45min, filter the extract for later use, and repeat the extraction twice. The filtrates were combined and concentrated to a thick paste for subsequent use;

[0022] 4. Put 63g of Radix Astragali and 64g of Radix Paeoniae Alba into an extraction tank, add 8 times the amount of water, decoct and extract for 2 hours, filter the extract for later use, and repeat the extraction three times. T...

Embodiment 2

[0025] 1. Take 64g of Baiji, 63g of squid octopus, 38g of gallinaceous gold, 1g of egg shell (scrambled) and 13g of Baicao cream, and carry out ultrafine grinding, pass through a 200-300 mesh sieve, and make ultrafine powder for later use;

[0026] 2. Take 63g of frankincense and 15g of myrrh to pulverize with an ultra-low temperature pulverizer, pass through a 180-300 mesh sieve, and make superfine powder for later use;

[0027] 3. Take 64g of Panax notoginseng and 64g of Cyperus cyperi, crush them into fine powder, add 75% ethanol, conduct ultrasonic continuous countercurrent extraction for 60min, filter the extract for later use, and repeat the extraction twice. The filtrates were combined and concentrated to a thick paste for subsequent use;

[0028] 4. Put 63g of Radix Astragali and 64g of Radix Paeoniae Alba into an extraction tank, add 8 times the amount of water, decoct and extract for 2 hours, filter the extract for later use, and repeat the extraction three times. T...

Embodiment 3

[0031] 1. Take 64g of Baiji, 63g of squid octopus, 38g of gallinaceous gold, 1g of egg shell (scrambled) and 13g of Baicao cream, and carry out ultrafine grinding, pass through a 200-300 mesh sieve, and make ultrafine powder for later use;

[0032] 2. Take 63g of frankincense and 15g of myrrh to pulverize with an ultra-low temperature pulverizer, pass through a 180-300 mesh sieve, and make superfine powder for later use;

[0033] 3. Take 64g of Panax notoginseng and 64g of Cyperus cyperi, crush them into fine powder, add 85% ethanol, conduct ultrasonic continuous countercurrent extraction for 30min, filter the extract for later use, and repeat the extraction twice. The filtrates were combined and concentrated to a thick paste for subsequent use;

[0034] 4. Put 63g of Radix Astragali and 64g of Radix Paeoniae Alba into an extraction tank, add 8 times the amount of water, decoct and extract for 2 hours, filter the extract for later use, and repeat the extraction three times. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com