Membrane treatment method of landfill leachate concentrate

A technology for landfill leachate and concentrated liquid, which is applied in the fields of dehydration/drying/concentrated sludge treatment, chemical instruments and methods, and multi-stage water/sewage treatment. and other problems, to achieve the effect of low processing cost, low equipment investment and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

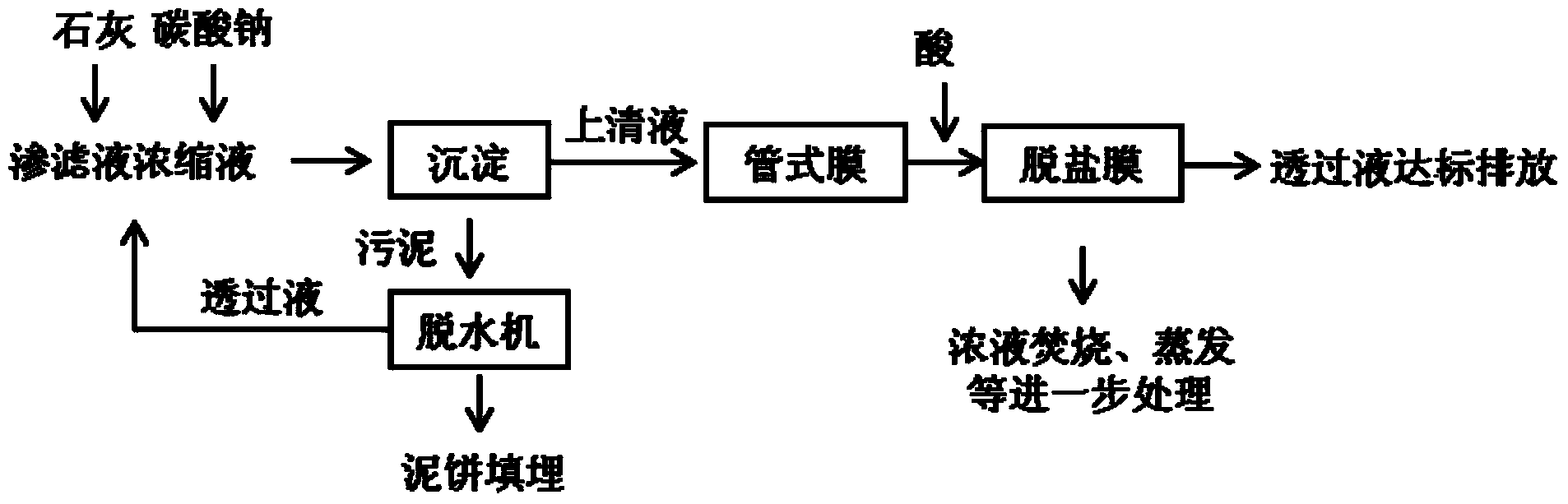

[0030] Such as figure 1 Shown, the membrane treatment method of the landfill leachate concentrate of this implementation, its steps are as follows:

[0031] 1) Add 0.5g / L lime to the landfill leachate concentrate, stir and mix for 5 minutes, then add 0.2g / L sodium carbonate, mix and stir for 5 minutes, and settle for 1 hour;

[0032] 2) Filter the precipitated supernatant with a tubular membrane ultrafiltration membrane to remove impurities such as suspended solids and colloids in the concentrated solution, and obtain a turbidity of 0.3 NTU in the filtrate;

[0033] 3) adding hydrochloric acid to the tubular membrane permeate to adjust the pH value to 7;

[0034] 4) Use the reverse osmosis membrane to treat the concentrated solution after adjusting the PH value. The permeated solution COD is 45mg / L, total nitrogen is 15mg / L, and the chromaticity is 1, reaching the discharge standard, and the water recovery rate is 50%;

[0035] 5) Use a plate and frame filter press to dehydr...

Embodiment 2

[0037] Such as figure 1 Shown, the membrane treatment method of the landfill leachate concentrate of this implementation, its steps are as follows:

[0038] 1) Add 2g / L lime to the landfill leachate concentrate, stir and mix for 15 minutes, then add 0.5g / L sodium carbonate, mix and stir for 15 minutes, and settle for 2 hours;

[0039] 2) Filter the precipitated supernatant with a tubular membrane microfiltration membrane to remove impurities such as suspended solids and colloids in the concentrated solution, and obtain a turbidity of 0.5 NTU in the filtrate;

[0040] 3) Add hydrochloric acid to the tubular membrane permeate to adjust the pH value to 6.5;

[0041] 4) Using nanofiltration membrane to treat the concentrated solution after adjusting the pH value, the permeated solution COD85mg / L, total nitrogen 25mg / L, chromaticity 1, reached the discharge standard, and the water recovery rate was 65%;

[0042] 5) Use a belt filter press to dehydrate the sediment to form a mud c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com